Businesses use a host of methodologies to bring structure to the process of identifying and acting upon opportunities for improvement. You may be familiar with Six Sigma, Kaizen, Lean, Toyota Production System, and others. Although these methodologies differ, the foundation of each of them is the continuous improvement model.

The continuous improvement model reflects the idea that organizations should constantly implement incremental improvements to services, products, and processes. The approach applies to every industry and size of business. Several central principles guide the continuous improvement model.

Principle 1: Standard work must be defined

The first principle that standard work must be defined is often overlooked, but it is the bedrock of continuous improvement. Standard work is the current best practice for any activity or process. It must be well documented, created by the process operators, and readily available in the place where work is done.

Standard work becomes the foundation upon which improvement happens. When there is a suggested improvement, the team begins a structured cycle such as PDSA or DMAIC to test potential adjustments to the standard. If the change results in a measurable, sustainable improvement, the standard is updated, and the process starts again with the subsequent improvement idea.

Principle 2: Improvements are based on small-scale changes rather than significant paradigm shifts or new inventions

This element of improvement culture is essential because significant changes often feel frightening and destabilizing to organizations. By approaching change in small, incremental steps, the continuous improvement model reduces the fear factor and increases the speed of improvement. Following this principle, the organization does not need to wait for a strategic shift or a new product release to advance.

Any idea that eliminates waste, speeds production times, reduces defects, or allows employees to develop new skills is worth exploring. In addition, this approach opens the door to considering small-scale proposals to improve processes and enable employees to do their best work.

Principle 3: Employee ideas guide improvement work

The continuous improvement model relies greatly on employees, not only leadership, to identify opportunities for improvement. This bottom-up improvement model is effective because employees are closest to the problems and thus better equipped to solve them.

When thinking of these two principles, consider the value of engaging your staff. If you ask everyone in the organization for ideas to create a new product line or revolutionize how they care for their patients, you're likely to get little input; staff members are focused on their day-to-day work. They, understandably, can't come up with monumental ideas that change the organization's direction.

Instead, ask people what improvement they could make to save them 5 minutes a day. Then empower them to implement that improvement, and spread it to everyone else in the organization doing the same type of work. This way, you can take a small idea that anyone could come up with and drive a significant impact. For example, if you get one idea from ten employees, each of which saves them five minutes daily. That's ten ideas. Share all ten of those improvements with one hundred other employees so that each one saves fifty minutes per day (10 ideas x 5 minutes each).

By asking people for a small idea that shaves 5 minutes off their day and propagating those ideas around the organization, you're about to save 3.4 YEARS of manpower with the ideas of just ten people. Imagine how much you would save if you extended the "ask" of a five-minute idea to your entire organization!

Another way to encourage employees to spot opportunities and implement improvements is to ask, "What keeps you from doing your best work?"

Most complaints involve a delta between the current state and the employee's idea of how things should be. Sometimes the issue includes a specific recommendation. It might go something like, "If they would just do X, Y, and Z, the problem would be solved." Sometimes there is no solution included. You might hear, "There's got to be something they could do to fix this!"

Did you notice the operative word in each of these examples? They. When employees are disempowered and disconnected from the improvement process, all they can do is wait for "They" (management) to recognize and correct problems. When that doesn't happen, it's natural (and probably healthy) for people to express their frustration.

Leaders who adopt the continuous improvement solutions don't shy away from employee complaints.

Quite the contrary, they embrace them as opportunities for improvement. If a team member notices something amiss and says something about it, that's a good thing. Gathering employee ideas is the beginning of the improvement cycle. Companies with a culture of improvement take it even further. They give employees a process for reporting and acting upon ideas to save money, improve processes, satisfy clients, and improve quality. What's more, they provide systems and structure for doing so and recognize those who contribute to improving the organization one small initiative at a time.

People are often told not to complain unless they are willing to do something about it. That's only fair when there is something they can do. Good leaders give people that opportunity.

Principle 4: Incremental improvements are typically inexpensive to implement

Employees tend to focus on small changes that can be accomplished without much expense. Many ideas from employees involve eliminating process steps rather than adding them, which is an excellent way to ensure that every activity adds some value to the customer and reduces wasted effort.

We have the benefit here at KaiNexus of seeing the detailed improvement data of organizations at every stage of the improvement journey around the world and in nearly every industry. Through examining that data, we've discovered that 1.4% of improvement ideas have an impact of over $100,000, and each employee has an average annual impact of $25,000. So, not only are these ideas inexpensive to implement, but they can also have a massive effect on your bottom line.

Principle 5: Employees take ownership and are involved in improvement activities

Getting people to change the way they've always done things is hard. What makes it easier is rolling out changes that originated from the front lines. When people develop ideas to improve their work, they intrinsically see the value of change.

By engaging your staff in the continuous improvement model, you empower them to take charge of their work. As a result, they can identify problems or opportunities for improvement, follow through on implementing their ideas, take credit for the work, and see a measurable impact from their efforts. This way, the sole burden of improvement and process management is lifted from managers, who can spend their time more effectively coaching staff on improvement techniques and removing barriers to implementing changes.

For more information about overcoming resistance to change, check out this free webinar:

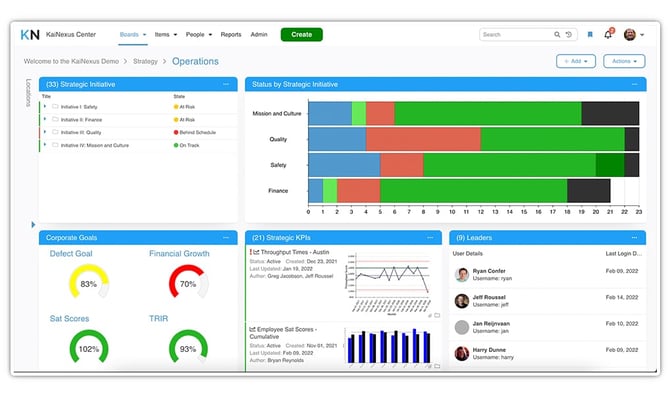

Principle 6: Improvement work is aligned with the strategic goals

While daily improvement is employee-led, properties are decided based on the organization's strategic goals. Through a process called policy deployment or strategy deployment, the organization's long-term and annual goals are cascaded from the top level through the departments and down to the individual employee level.

Aligning objectives this way serves multiple purposes:

|

1. It makes decision-making more manageable by getting everyone on the same page about the most critical priorities. |

|

|

2. It helps employees connect their day-to-day work to the bigger picture so that they develop an emotional investment in the outcomes. |

|

|

3. It connects each person to the organization's purpose and helps bring the "why" of what they do to life. |

Principle 7: The impact of incremental improvement should be measured and shared

If you look at the metrics most often used to measure an organization's results, you'll uncover a robust reporting framework based on financial results. Profitability, earnings, and expenses are apparent indicators of a company's success. In addition to financial results, most companies have measurements around customer satisfaction, human resources, and compliance.

Continuous improvement has the potential to improve every one of these and other organizational effectiveness measures that one might track. While many organizations track the ultimate artifacts of improvement work, only some do a great job of tying improvement activities to the final results. However, measuring, monitoring, and reporting on improvement is an effective method for ensuring that the organization meets its strategic goals and outperforms the competition.

Because the continuous improvement model relies on employees for ideas for improvement, each person becomes more invested in the outcome of the change, and employee engagement increases. The focus on improvement increases the chance of successful, sustainable positive change. Improved employee engagement also positively impacts retention, customer service, product quality, and recruiting.

Add a Comment