When we chat with people about their business goals, many reveal that the idea of business process improvement is somewhat overwhelming. There are methodologies, such as Lean manufacturing and six-sigma, that involve tons of tools and techniques that seem complicated and impossible to implement. Many people feel that process improvement is something that only big corporations can manage and benefit from.

When we chat with people about their business goals, many reveal that the idea of business process improvement is somewhat overwhelming. There are methodologies, such as Lean manufacturing and six-sigma, that involve tons of tools and techniques that seem complicated and impossible to implement. Many people feel that process improvement is something that only big corporations can manage and benefit from.

Fortunately, that’s not the case at all. We are huge fans of structured improvement tools like DMAIC, PDSA, 5S, A3, and the rest, but we don’t blame you if you find the jargon and acronyms confusing. When you peel back the onion layers, all of these sophisticated techniques are trying to do the same thing—make work more efficient and produce more value for the customer. The structure is important, but it doesn’t have to be complex.

If you are new to process improvement, try these fundamental ideas.

Standard Work

Standard work is the simple idea that before you can start to improve a process, you must document how it is done and ensure that everyone does it the same way every time. This is necessary to measure your results and get a baseline on what you want to improve. The first step is to agree on and record the current best practice for the process. The people who operate the process should be the ones to create the Standard. Make sure that the document includes any useful images and charts. Ideally, it will be available in an online quality management system so that it is accessible by everyone who needs it. The process should always be performed to the Standard until an improvement is implemented.

Visual Management

We are wired as human beings to respond to visual information very quickly. It’s how our ancestors avoided danger and what makes it possible for us to do complex tasks like drive a car. In fact, your car’s dashboard is an excellent example of visual management. It doesn’t tell you that you have 3 gallons of gas left, it shows you a gauge that makes it clear you are getting close t

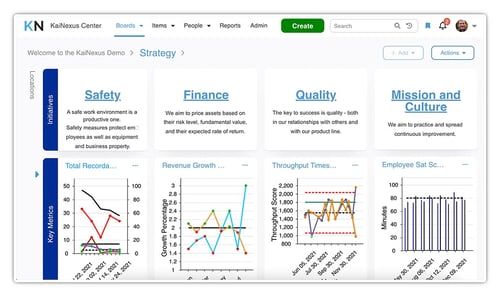

In business process optimization, dashboards and charts are used to visualize the flow and results of work. Creating a chart of process results, for example, lets you quickly spot trends and anomalies. Do you see consistent results over time, or is there a lot of variation? Do you know what might have caused a spike or dip in the graph?

Another way to use visual management is to create a board that shows work as it flows through the process or across multiple processes. You’ll quickly see if operations are waiting for input or backlogs that inhibit the flow of work. Digital boards make it easy for everyone to be engaged in finding opportunities to resolve workflow issues.

Workplace Organization

It is worth noting that sometimes the best way to improve a business process is to improve the place where the work is done. Poorly organized workspaces can introduce unnecessary waste and risk into process operation. Start by asking the following questions:

- Are the things that people need most frequently or urgently available in the workspace?

- Is equipment cleaned and maintained regularly to meet standards?

- Is there a documented standard for the space?

- Who is responsible for maintaining the workspace standards?

Of course, these days, many people are working remotely. That doesn’t mean you can ignore workspace organization. For remote workers ask:

- Does each employee have the equipment and technology they need to be efficient from home?

- Have employees been trained about ergonomics?

- Are there procedures for reporting challenges with working in a remote space?

The 5 Whys

The 5 Whys is a brilliantly simple technique for discovering the root cause of a problem or waste. When something goes wrong, you simply ask “Why?” for multiple iterations (usually around 5) until you find the underlying reason, and therefore the path to an effective solution.

For example, if an increasing number of customers are abandoning your call queue, you might have a conversation like this:

- Why are more customers leaving the call queue?

- Because hold times are increasing.

- Why are hold times increasing?

- Because we are getting more calls?

- Why are we getting more calls?

- Because customers are confused about the new feature.

- Why are customers confused about the new feature?

- Because it isn’t documented on the website.

In this case, it may initially have seemed like a call center problem, and maybe the knee-jerk reaction to the abandonment problem would have been to add more call center agents, but after going through just 4 Whys in this case, it became clear that the problem wasn’t related to the call center at all. Therefore, the solution involves more documentation, not more agents.

These are some simple techniques that any organization can implement today without expensive business process consultants or complicated procedures. Your approach to improvement will become more sophisticated over time, but by starting with these, you’ll take the first steps to meeting your most imperative objectives.

![[Watch Now] The Why, How, and What of Continuous Improvement](https://no-cache.hubspot.com/cta/default/326641/060c8cc9-44ad-4fd1-ad7b-7b4ab71c7632.png)

Add a Comment