When you’re a Lean consultant, a big part of your job is to visit your clients on site and help coach them and build their Lean or continuous improvement program. Of course you want to have a big impact while you’re there, but more importantly, you want the results you help your clients achieve to sustain in the long run. In order for that to happen, you need visibility into what your clients are doing on a daily basis.

If you’re lucky, all of your clients are right in your backyard.

But what if they’re more spread out? What if they have multiple locations around the country - or even the world? You might be in San Francisco one week and New York the next.

What problems arise when your clients are spread out and you can’t be everywhere at once?

First is actual travel logistics. The more time you spend traveling, the less time you have to actually help clients, whether at home or on site.

The second problem is visibility across an organization. How can you compare two branches of the same company in different locations? How do you know what parts of the organization need the most coaching? When you’re one person trying to coach a large, dispersed organization, it’s nearly impossible to stay on top of the improvement culture at each site.

Even more significant than that, the biggest problem I hear from consultants is also their biggest fear: What if they leave and come back in a few months to find that nothing has changed?

These are all problems that improvement software can solve. The right technology gives consultants the ability to help clients even when they’re not on site, provides the visibility they need to compare any groups in an organization and have powerful reporting capabilities that pinpoint the areas that need the most attention to maximize their impact.

There are lots of improvement software features that make the job of a consultant significantly easier, but here are two of the most important:

Boards

Let’s take a look at this one from the most basic level. When your clients are managing their improvement work on analog boards (huddle boards, idea boards, kanban boards, etc) - how do you know what they’re doing in between on-site visits? Chances are, you’re depending on the client to send you pictures of the board, or reach out when they feel there’s a problem, or send updates on what they’re working on - or maybe you have no way to keep an eye on improvement between your visits.

When your clients manage their improvement work in digital boards, they can still display them on the wall (using mounted screens), but with the added benefit of being available to you on at any time, anywhere, using your computer.

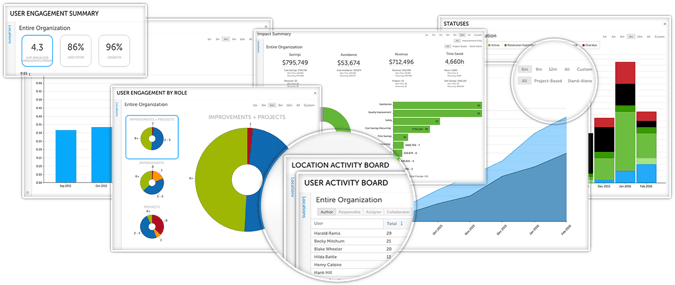

Perhaps even more significantly, consultants are able to use improvement software to set up their own boards for each client that they can then use to track improvement, measure activity, and evaluate the health of the improvement culture of each client at a glance. You can track and compare multiple locations, and use bottleneck boards to identify problem areas before they spiral out of control. Using this information and visibility, you’re then able to reach out to the improvement leaders and coach remotely when you can’t be on site.

Reports

Continuous improvement software provides unparalleled access to improvement culture data using automated reports, enabling both consultants and improvement leaders to maximize their impact and extend their reach. Automated reporting gives an overview of staff and manager engagement, shows participation and submission activity, improvement health indicators, and tracks ROI reporting to show the direct impact that a consultant is having on an organization. These reports can also be used to drill down into the details to see the participation and impact of even small groups or teams to identify and celebrate the top performers in an organization.

Continuous improvement software gives greater visibility for an organization and gives one person or a small team a greater reach and ability to make an impact. With the right technology, you’re able to spend less time catching up and looking for areas that need your help, and instead, spend more time focusing on organizational improvement and coaching.

Lean consultants drive organizational process improvement - I would argue that it’s time to take a look at how to improve their own consulting process.

Add a Comment