TL;DR: Gemba walks aren’t about walking around — they’re about learning how work actually happens, building trust with frontline teams, and turning observations into sustained improvement.

Gemba walks have become a widely adopted management technique. Leaders gain valuable insights into organizational value stream flow and often discover improvement opportunities by directly visiting the work environment. This collaborative approach involves employees sharing details about their tasks and the reasons behind them.

Why are Gemba Walks Important for Organizational Success?

Gemba walks are important for several reasons. They provide leaders with a firsthand understanding of the work environment, allowing them to observe processes and interactions directly. This enables the identification of inefficiencies, bottlenecks, and opportunities for improvement. Gemba walks foster a collaborative approach by involving employees in discussions about their tasks and processes, encouraging open communication and idea-sharing. The insights gained during Gemba walks contribute to informed decision-making and strategic planning as leaders develop a deeper appreciation for the challenges and successes occurring at the operational level. Gemba walks are a key practice for continuous improvement, enhancing transparency, employee engagement, and overall organizational effectiveness.

The Qualitative and Quantitative Benefits of Gemba Walks

Gemba walks can impact the bottom line in both qualitative and quantitative ways:

Qualitative Impact:

Improved Communication: Gemba walks enhance communication between leadership and frontline employees, fostering a culture of openness and collaboration. This can lead to improved teamwork and a positive work environment.

Employee Engagement: By involving employees in discussions about their work processes, Gemba walks increase engagement. Engaged employees are more likely to contribute innovative ideas and feel a sense of ownership in their roles.

Continuous Improvement Culture: Gemba walks foster a culture of continuous improvement by identifying opportunities for improvement. This culture can lead to more efficient processes, reduced waste, and increased overall effectiveness.

Quantitative Impact:

Increased Productivity: Observing processes during Gemba walks can lead to changes that enhance productivity. This may result in measurable increases in output per unit of input, positively impacting the bottom line.

Cost Reduction: Identifying and addressing inefficiencies directly reduces costs. Whether it's streamlining workflows or minimizing waste, the financial impact can be significant.

Quality Improvement: Gemba walks can lead to improvements in product or service quality. Higher quality often translates to customer satisfaction, loyalty, and, ultimately, increased revenue.

Shorter Lead Times: Understanding the workflow through Gemba walks may lead to streamlined processes and reduced lead times. This can result in faster delivery of products or services, thereby improving customer satisfaction and generating revenue.

Listen to the post:

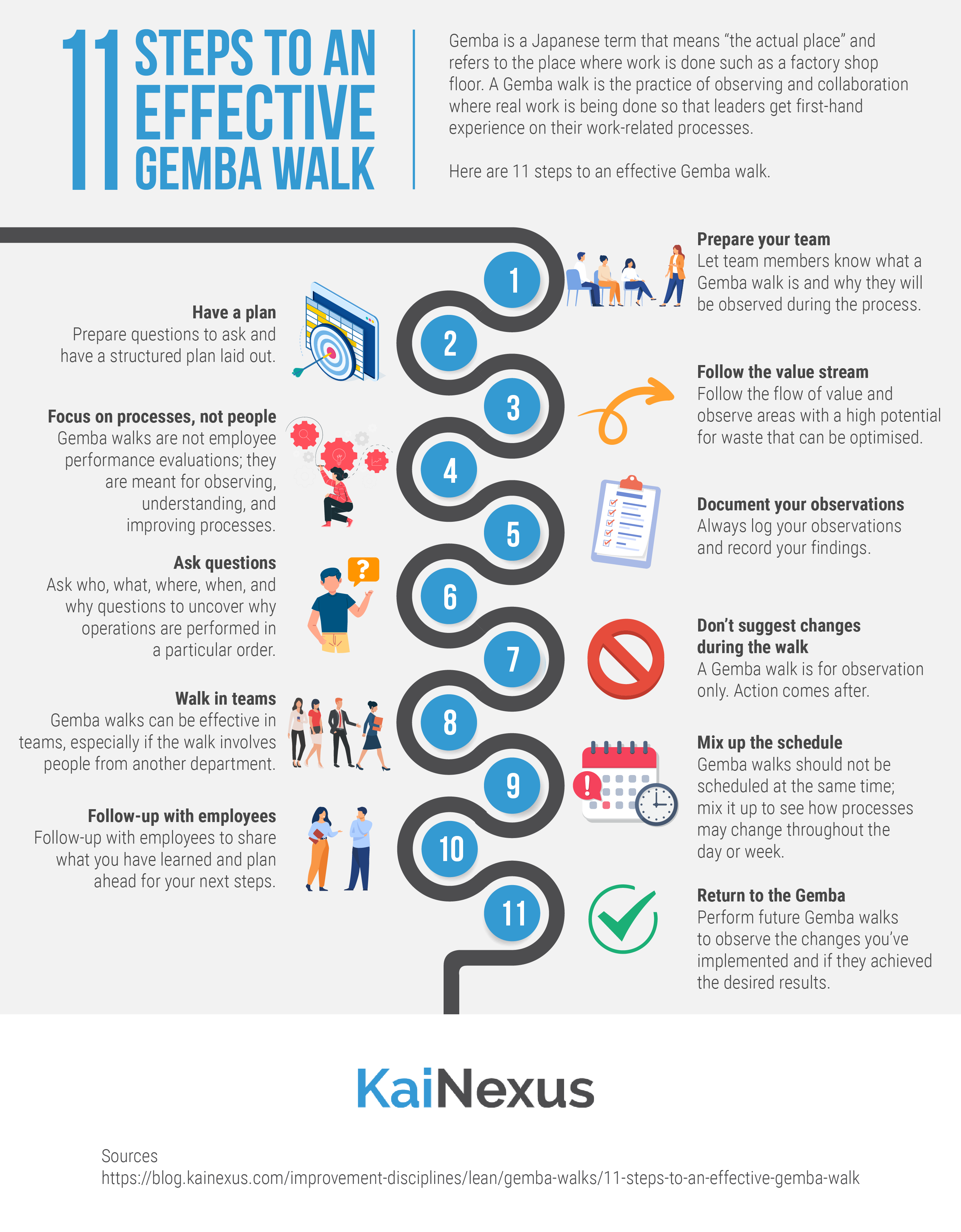

Steps to Prepare for an Effective Gemba Walk

Great results depend on thoughtful planning, execution, and follow-up. Here are the most important steps you can take to ensure that your next Gemba walk is successful.

1. Prepare the Team

It is crucial that team members participating in the Gemba walk have a clear understanding of its purpose and benefits. They should recognize that the ultimate goal is to eliminate obstacles hindering their ability to contribute the maximum value. Discussing the walk in advance helps create a comfortable and open atmosphere, ensuring everyone is prepared and receptive to the interaction.

One easy way to do that is to send out this free eBook about Gemba walks to the team who will be participating:

2. Have a Plan

Gemba walks should not be confused with Management by Walking Around (MBWA), a different approach in which leaders simply wander about and get involved in what employees are doing. A Gemba walk should have a defined purpose, often associated with a specific concern related to a KPI.

During a Gemba Walk, the manager asks very in-depth questions about the process being observed. Who is involved? What materials are used? What do you do? How do you know what to do? When does the task take place? What depends on the outcome? MBWA does not involve that degree of depth, nor does it usually have the same focus on asking open-ended questions.

In fact, Dr. W. Edwards Deming, often called the Father of Quality Evolution, said in his 1982 work, Out of the Crisis, “ ‘Management by walking around’ is hardly ever effective. The reason is that someone in management, walking around, has little idea about what questions to ask, and usually does not pause long enough at any spot to get the right answer."

Organizations that effectively use Gemba Walks will create structure. For example, ThedaCare has created "STAT sheets" that provide consistent questions to be used by leaders at each level. Leaders also spend time at the Gemba to make sure they better understand the work... but at the same time, they don't worry about becoming experts in the work, because they can rely on the insights and expertise of front-line staff.

3. Follow the Value Stream

Frequently, the most significant improvement opportunities arise at the interfaces between processes, departments, or individuals. By tracing the flow of value, these critical points, prone to potential waste, can be observed, and underlying issues can be uncovered.

Encouraging employees to propose processes, shifts, or work areas for a Gemba Walk is a valuable approach. This not only may reveal opportunities for improvement that might have been overlooked but also transform the process into a collaborative effort. Since frontline employees are actively engaged in the work, they are likely to provide insights into processes and areas that could benefit from an additional perspective. It's essential to recognize that the value brought to the table lies in offering a fresh perspective on existing processes. By involving people in identifying where this perspective would be most beneficial, you engage them in the improvement process and convey a supportive rather than critical approach.

4. Always Focus on the Process, Not People

A Gemba walk is not intended as an employee performance evaluation; its purpose is to observe, comprehend, and ultimately enhance processes. The walk should never carry a punitive tone, and it is not the appropriate time for engaging in employee task management.

Preparing employees for the Gemba walk is beneficial by informing them that you'll be asking numerous questions about how, when, and why tasks are executed. Emphasize that you are not seeking "right" answers; rather, you value responses that are honest and comprehensive. If tasks do not align with the standard, you want them to acknowledge rather than conceal it. It's crucial for them to recognize that your inquiries stem from a genuine desire to comprehend, devoid of any accusatory or confrontational intent.

5. Document Your Observations

Because there's a lot going on during a Gemba walk and you'll want to remember it all later, it's important to bring along tools to log your observations, including:

A way to log observations – While we risk stating the obvious here, a way to jot down your observations is essential because the time to react to what you observe is after your Gemba walk, not during it. You’ll need a way to remember what you saw and thought. Ideally, you'll be able to submit your observations into a continuous improvement platform via a cell phone or tablet so that you can follow up on them later, track their implementation, and record the impact of your Gemba walk. A pen and paper will do in a pinch, but make sure that you still follow up on them afterward.

A camera – It may be very useful later to browse through a gallery of images or maybe even a few quick bits of video. Be sure to be respectful of any people you might photograph. If cameras are not appropriate for your workplace, some graph paper for sketching out the layout of people and equipment may be useful.

An open mind – You don’t want your observations to be tainted by preconceived notions. For example, don’t assume that work is being performed to the Standard or that each person performs each task in the same manner.

6. Ask Questions

During a Gemba walk, one of the challenges is setting aside preconceived notions about why work is conducted in a specific manner. Avoid assuming that everything adheres to the standard procedure. Instead, inquire with employees about the reasons behind their work processes. Ask about the documentation of tasks, their approach to handling exceptions, and the rationale behind the sequence of operations.

The 5 Ws provide an excellent structure for the questions you want to ask and answer during your Gemba Walk.

- Who – Who are the people involved in the processes that you observe? Who provides input for the processes? Who are the “customers” of the process? Pro tip: You shouldn't be asking who to blame for problems...

- What – What are the inputs and outputs of the process? What obstacles inhibit flow or produce waste?

- Where – Does the space where the work is performed conform to 5S? Are necessary materials and equipment conveniently located? Do you notice the waste of motion?

- When – Are process inputs available when needed? Is work from this process being pulled through by the next, or do outputs sit idle? Is the waste of waiting observed?

- Why - What value does this work add for the customer?

7. Don’t Suggest Changes During the Walk

A Gemba walk provides an observational opportunity rather than an immediate call to action. While the temptation to swiftly implement solutions is strong, it is essential to refrain and allow a period of reflection before making changes. Introducing solutions abruptly undermines individuals' capacity to learn and practice independent problem-solving. Implementing an improvement cycle like DMAIC or PDSA ensures that any changes made are well-considered and targeted to eliminate the identified issues, with involvement from the individuals directly engaged in the work.

8. Walk in Teams

While not every Gemba walk needs to be a team endeavor, bringing along a leader from a different functional area of the organization can be a good way to get another point of view. People who are less familiar with a process might ask a different set of questions that shed light on the work in a new way.

Who should come along on a Gemba walk? Consider:

A peer from another department – It is easy to become so conditioned to problems that we see frequently that we don’t even notice them. A second set of eyes, less familiar with the processes and tasks of your team might be very valuable, especially if you take frequent Gemba walks.

A vendor – If your team uses equipment, consumable products or software, it might be useful to invite the vendor along on your walk. They may be able to suggest best practices or notice errors in how the product is being used. They may even uncover ways that they could improve the product to better fit your needs.

A customer – This might be controversial, and it certainly isn’t always a good idea, but today’s customers value transparency and they are often interested in seeing how the sausage is made, so to speak. They may also be able to identify things that they value less than you think.

One of your sales representatives – It is important that the people who pitch your product to customers know how it is created and understand how every part of the process relates directly to customer value.

9. Mix Up the Schedule

We strongly advocate for leaders to schedule Gemba walks in their calendars, but it should not become a routine occurrence set for the same time each month. To gain a comprehensive understanding of the process, it is advisable to conduct Gemba walks at varying times of the day, days of the week, and different parts of the month.

10. Follow-up with Employees

Sometimes, the results of a Gemba walk will be immediately obvious as changes are made or an improvement cycle is started, but even if there will be no immediate action as a result of a particular walk, it is important to follow up with employees. Share what you have learned and communicate what next steps, if any, will occur.

Many organizations turn to improvement software to help manage the follow-up that should occur after the Gemba walk.

Because improvement software lets users capture ideas for improvement and execute on those ideas in the same platform, more improvements identified on a Gemba Walk actually get implemented.

It is easy for managers to assign improvement projects generated by the Gemba walk to individuals or teams, removing the friction that slows progress afterward. Smart notifications keep everyone in the loop and help make sure that nothing falls through the cracks. Aside from the features that help organize and streamline this work, implementing technology of this sort sends a powerful signal to the team that incremental improvement is important, that managers aren’t just asking for employee input for the sake of looking engaged during a Gemba walk, and that leadership is willing to make the investment necessary to propel positive change.

11. Return to the Gemba

If changes are implemented following a Gemba walk, be sure to return to the Gemba to observe those changes and verify that the desired result has been achieved. KPIs can give you some idea of how well the improvement is working, but nothing is as useful as first-hand observations.

A big objection to this that a lot of people have is that they're too busy for regular Gemba walks.

My answer to that is that many of the activities that take up so much time can be eliminated by Gemba Walks. You don’t need to send emails back and forth or form a committee to hold a meeting to address many common process or workspace issues. A first-hand look can save many hours of reading second or third-hand accounts about an issue. The human brain processes images way more quickly than text, after all. Anything that speeds your understanding of what’s happening on the front lines reduces the amount of time you have to spend trying to figure it out from afar.

Best Practices During a Gemba Walk: Key "Dos"

Whether your Gemba Walks are virtual or in person, there are a few best practices to follow and a few pitfalls to avoid.

DO Focus on the process:

The purpose of the Gemba Walk is to observe processes, not to evaluate the people preforming the process.

DO Observe and learn:

It is useful to adopt the mindset of a student during a Gemba Walk. Keep an open mind and ask lots of open-ended questions. The leader is there to learn, not to judge or to give unwarranted advice.

DO Mix it up:

You want to perform Gemba Walks at different times of day and different days of the week to get a complete picture of the state of the value stream.

DO Test assumptions:

During and after the Gemba Walk, validate any assumptions with the people who are performing the process. Don’t make any guesses about what they are doing or why.

DO Walk with a cross-functional team:

It can be very enlightening for people to see processes and work activities in which they aren't normally involved. A diverse team can offer a greater array of new ideas.

Common Pitfalls to Avoid: Key "Don'ts"

DON'T Adjust the process or correct employees during the walk:

The purpose of the walk is to understand the current state. Improvement happens later, following analysis and reflection.

DON'T Confuse Gemba with MBWA (Management by Walking Around):

Management by Walking Around is an approach that encourages management participation in the work affairs of employees. Gemba, on the other hand, is about observation and deliberation. MBWA has often devolved into walking around, saying hello, and slapping people on the back. That's not very helpful.

DON'T Rely on the manual:

A Gemba Walk is the time to observe what is actually happening, not what has been documented as the policy or standard work. The result of the Gemba Walk may very well be changes to documented procedures.

DON'T Forget to communicate:

It is important that all employees understand the purpose of the Gemba Walk and that the ultimate goal is to improve conditions, processes, and instructions for employees. The Gemba Walk should always be seen as positive, not punitive.

Examples of Improvements Resulting from Gemba Walks

Specific improvements resulting from Gemba walks can vary depending on the industry and context, but here are some examples across different sectors:

Manufacturing:

Reduction in machine downtime: Gemba walks identified maintenance issues, leading to improved preventive maintenance schedules and minimized downtime.

Enhanced production line layout: Observations on the shop floor led to a more efficient layout, reducing material handling time and improving overall production flow.

Healthcare:

Improved patient flow: Gemba walks in a hospital revealed bottlenecks in patient flow, leading to changes in scheduling and resource allocation for quicker and more efficient patient care.

Enhanced medication dispensing process: Observations in a pharmacy led to a redesign of the medication dispensing process, reducing errors and improving overall accuracy.

Office Environment:

Streamlined document approval process: Gemba walks in an office setting identified delays in document approvals, leading to the implementation of a more efficient approval workflow.

Improved communication channels: Direct observations highlighted communication gaps, resulting in the adoption of better communication tools and practices.

Retail:

Optimized shelf stocking process: Gemba walks in a retail store revealed inefficiencies in restocking shelves, leading to a redesigned stocking process for quicker and more organized shelf replenishment.

Enhanced customer service: Observations in customer service areas identified opportunities to improve response times and service quality, resulting in increased customer satisfaction.

Service Industry:

Faster order processing: Gemba walks in a service center identified delays in order processing, leading to the implementation of digital tools and process changes for quicker and more accurate order fulfillment.

Improved customer support workflow: Observations in a call center led to changes in the customer support workflow, reducing resolution times and improving customer experience.

These examples demonstrate how Gemba walks can pinpoint specific areas for improvement, leading to tangible enhancements in efficiency, quality, and overall performance across diverse industries.

Making Gemba Walks a Habit, Not a One-Time Event

Gemba walks deliver value only when they become part of a consistent leadership practice rather than an occasional activity. The real impact comes from returning to the workplace regularly, building trust with frontline employees, and demonstrating that observations lead to meaningful action.

Organizations that get the most from Gemba walks treat them as a learning system. Leaders observe, ask questions, reflect, and then support teams in solving problems at the source. Over time, this approach strengthens communication, surfaces hidden inefficiencies, and reinforces a culture where improvement is everyone’s responsibility.

Sustaining the benefits also requires a way to capture insights, prioritize opportunities, and follow through on changes. Without that structure, even the best observations can fade into good intentions. When supported by clear processes and the right tools, Gemba walks become a powerful mechanism for connecting strategy to daily work and ensuring that improvement efforts translate into measurable results.

Ultimately, the purpose of a Gemba walk is not simply to see what is happening — it is to help the organization get better at learning from what it sees. Companies that embed this discipline into their leadership routines build a lasting advantage: they solve problems faster, adapt more effectively, and continuously improve how work gets done.

Add a Comment