A popular ice breaker in business meetings these days is, “3 Truths and 1 Lie.” Each person says three true things about themselves and one made up thing and everyone tries to guess which is the lie.

A popular ice breaker in business meetings these days is, “3 Truths and 1 Lie.” Each person says three true things about themselves and one made up thing and everyone tries to guess which is the lie.

It’s a good way to get to know a bit about people and learn something about how they think.

There are similar visions of the game on social media. (“10 bands I’ve seen – and one lie,” is hot on Facebook right now.)

We thought that 10 truths and 1 lie would be a good way to introduce Standard Work, but we won’t make you guess which is a lie.

Listen to this Post and Subscribe to the Podcast:

10 True Things About Standard Work

- Standard Work is the basis for all improvement.

Taiichi Ohno, the father of the Toyota Production System, once said, “Without Standard Work, there is no Kaizen.” This makes a lot of sense. If you don’t have a repeatable, predictable process, you can’t improve it and the only way to have a repeatable, predictable process is for everyone to do it the same way each time.

- Standard Work makes onboarding new employees easier.

When each task in a process is clearly documented with the appropriate supporting materials, bringing on new team members is simplified and the time it takes to get them ramped up is shorter.

- Standard Work reduces defects and other waste.

Defects and waste are often caused by process variation and non-conformity. With Standard Work in place, results remain consistent and waste is reduced.

- Standard Work is developed by the people who do the work.

Managers, subject matter experts, and even consumers of what is produced during the process can be involved in developing the standard, but it is essential that the people who will ultimately complete the proscribed tasks be actively engaged in its development.

- Standard Work improves customer satisfaction.

Whether the customer for a given process is internal or external, they deserve to get what they expect, when they expect it. Only Standardized Work can achieve the predictability and consistency required to reach this goal.

- Standard Work is easily accessible.

Standard Work documentation must be readily at hand for the people who are doing the work. A cloud-based improvement management system is one way to make sure that everyone has access from wherever they happen to be.

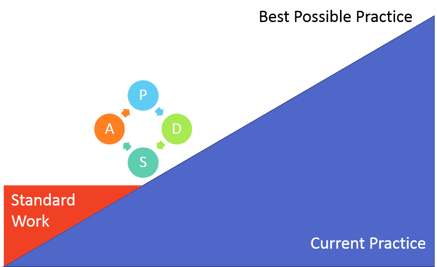

- Standard Work changes. Standard Work is the basis for improvement, not the last word on how a process must be performed. It must be reviewed periodically and updated when new best practices are identified, usually following an improvement cycle like PDSA or DMAIC.

- Standard Work improves profitability.

When the results of a process are consistent and predictable, finance teams can more accurately price products, taking into account the actual cost of production.

- Standard Work helps businesses scale.

It may be possible for a small number of experienced employees to make good decisions about a process on the fly, but when the team grows and more people are doing the work, that approach will no longer produce the desired outcome. Standard Work allows for teams to grow without introducing errors and waste.

- Employees like Standard Work.

People appreciate knowing what is expected of them, especially when they are the ones who set that expectation.

1 Lie About Standard Work

- Standard Work kills creativity.

When we broach the subject of standard work, we are often met with the question, “Doesn’t doing the same thing the same way every time kill innovation and turn people into automatons?” Nothing could be further from the truth. Standard Work is only the set of current best practices for doing a particular task. It can be thought of as a challenge for workers. It begs the question, “This is how we do it today. How could we do it better?” It not only provides a way for employees to understand what they are trying to improve, but it also allows for the measurement of the success of those improvements. Employees can take responsibility for managed change and can take pride when those changes yield better results.

An open dialog is essential in a culture of continuous improvement. Conversations about specific Standard Work and the approach in general should be encouraged and ongoing.Do you think your employees could spot the lie on this list? If not, then it might be a good time to have a conversation about what Standard Work is and what it isn’t.

Add a Comment