Organizations that embrace the Lean method of business management have many tools and techniques that they can deploy. That's one reason Lean is so popular; you get to select the best tool for the job and get started in an ordered and repeatable manner.

Technology supports many Lean methods in many ways and creates a unified platform for all kinds of improvement.

Here are just a few of the most valuable.

Catchball

Catchball is a Lean technique that involves sending ideas and information from one person or unit to another, much like the game of catch from childhood but with plans for improvement, rather than balls. It is the basis for complex decision making and strategy development. Email is not a useful tool for catchball because messages are often missed and context can be lost. Dedicated Lean software, on the other hand, is the perfect tool for this kind of collaboration.

Daily Huddles

Daily huddles are common events in Lean organizations. Departments or teams assemble around a huddle board to talk about projects and work together to solve problems. An improvement management platform transforms the huddle board into a digital asset, making it possible for people to participate from wherever they happen to be. It captures the history of improvement work and helps executives stay connected to the Lean activities of all the teams they manage.

DMAIC and PDSA

DMAIC (Define, Measure, Analyze, Improve, Control) and PDSA (Plan, Do, Study, Act) are versions of the cycle for continuous improvement. Each one ensures orderly and effective change. Lean software is useful for documenting each step of either cycle and notifying everyone involved when action is needed. It also measures the impact of improvement.

Gemba Walks

During a Gemba walk, managers visit the place where work gets done and identify opportunities for improvement. It is essential that improvements are never made during the walk, only after a period of assessment and reflection. Improvement software is the repository for each potential improvement that is identified. The technology supports the process for those opportunities that will be implemented.

Hoshin Kanri

Hoshin Kanri is a strategy development methodology that involves identifying three to five breakthrough objectives that can be accomplished in 3-5 years. Lean software supports this planning tool by aligning each person's goals with the overall strategy. The strategy stays top of mind because it is managed in the tool that they use for improvement work every day.

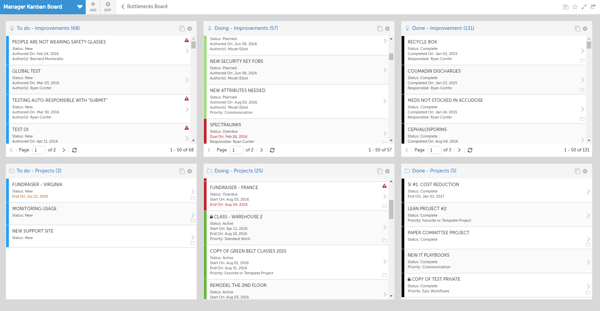

Kanban

Kanban is a Lean technique for visualizing workflow to find any interruptions in flow before a backlog forms or grows too big. Cloud-based Kanban boards help make it visible where work is getting delayed. This insight enables managers to take the proper steps to solve any problems.

Rapid Improvement (Kaizen) Events

Lean software ensures success by providing a unified platform for all improvement work that will take place. Related documents are stored, tasks are assigned, and progress is measured all in one online location. The top solutions provide notifications and alerts that help maintain forward momentum and provide a platform for collaboration. This matters most if the problem requires cross-functional effort. Often, new opportunities for improvement will be discovered during a Kaizen event. Lean technology helps capture them for future projects.

Standard Work

Improvement management software supports Standard Work in several ways. The work to develop the Standard is tracked as an improvement project, ensuring that all of the right people are involved. It also becomes a repository for the current Standard. Whenever the Standard requires revision, the cycle begins again.

Value Stream Mapping

Value stream mapping aims to compare the current state to an ideal state in which value is maximized, and waste is eliminated. One should think about value stream mapping software with that goal in mind. A solution that simply digitizes the value map doesn't go far enough to support the underlying purpose of improvement. Preferably, the focus should be on features that help to document, accelerate, and capture the results of improvement efforts.

These Lean tools can help any organization become more efficient and effective. They are even more impactful when online software is used to support them. It's a smart move to set your organization up for success by evaluating the available solutions.

![[Watch Now] How to Leverage Lean for Long-Term Success](https://no-cache.hubspot.com/cta/default/326641/eb5ac7b8-b040-48b7-810e-1589561ffff9.png)

Add a Comment