I'm here at the 2019 Lean Healthcare Transformation Summit in a keynote with John Toussaint, MD, the Executive Chairman of the Board at Catalysis.

Actual footage of me right now:

I know I'm probably driving the people around me right now bonkers with the speed typing, but when Toussaint kicked off his presentation with a video of his grandson learning how to walk, I knew this was going to be a good presentation that I was going to have to share with you all.

The video wasn't just a clever way of showing off a cute video of his grandson (though it was), or a way to get people to practice using the sli.do app before it really mattered later in the presentation (which it did) - it illustrated Toussaint's purpose for why he does the work that he does with Catalysis.

For Toussaint, family is the answer to his "why." He wants them to be safe, to get good healthcare. That's why we do this - to make our families safe. Lean is the method that keeps our families safe. It's no coincidence death rates for surgical patients with serious, treatable conditions and unplanned remission rates are statistically, significantly, lower in hospitals that apply the Lean method.

Here are some of Toussaint's questions we must be able to answer to spread Lean and thrive in today's economy.

What is the underlying management philosophy?

The first question John Toussaint says we must be able to answer is "Do you have a management philosophy?" It's critical for Lean leaders to be able to articulate that philosophy, so that others can get on board. Are you able to define your philosophy? Are you able articulate it to your peers? To your staff? To your leaders? If you ask someone else in the organization what the management philosophy is, will they give the same answer? Getting the entire organization on the same page with regard to a management philosophy is a critical first step.

What is the management philosophy based on?

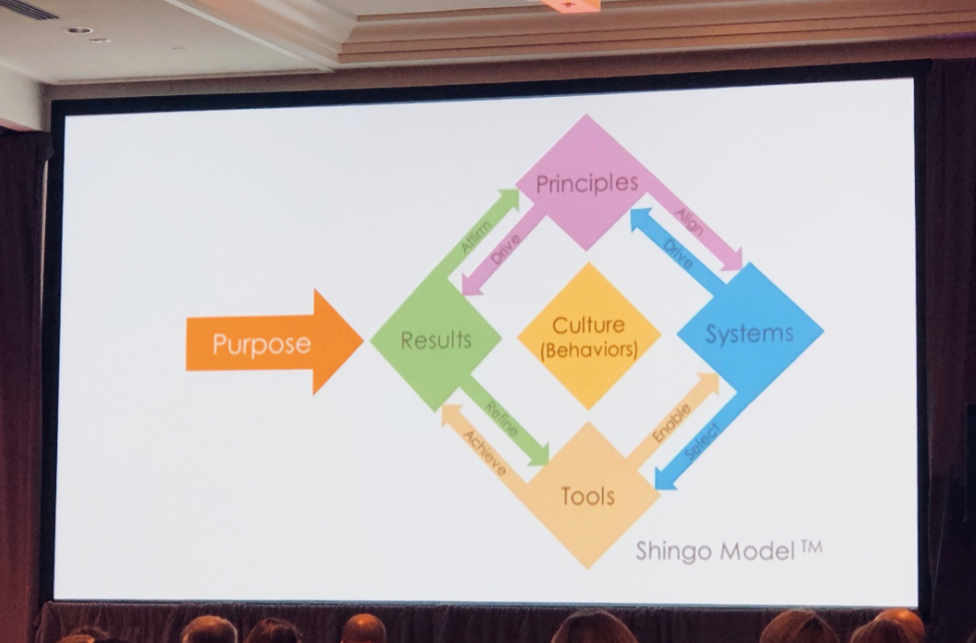

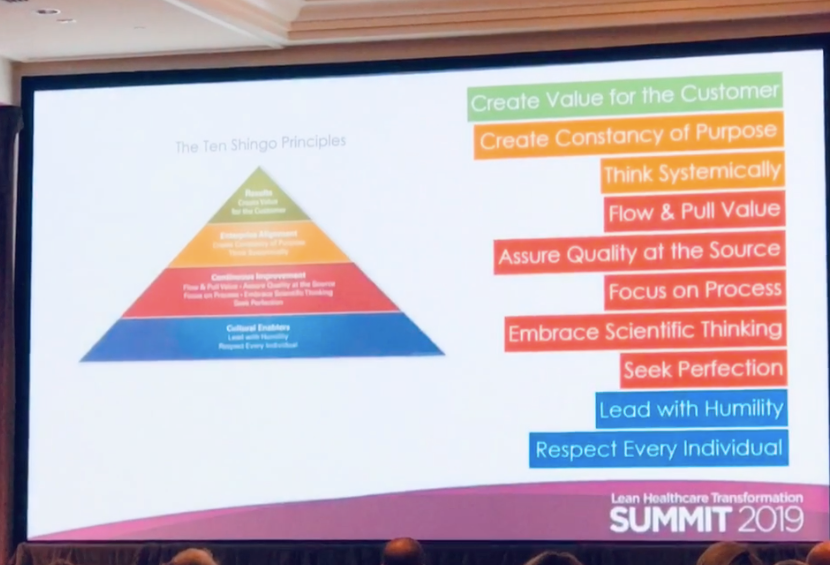

Your management philosophy should be based on your organization's underlying principles. Toussaint encourages focusing on the 10 Shingo Principles, which effectively explains how you can successfully create the bedrock for your organization. The foundation of these principles rests on Cultural Enablers: Leading with Humility, and Respecting Every Individual.

Next comes Continuous Improvement, which includes Seeking Perfection, Embracing Scientific Thinking, Assuring Quality at the Source, and the Flow & Pull of Value.

Once these are in place, then comes Enterprise Alignment - including Thinking Systematically and Creating a Constancy of Purpose.

The top of the pyramid - the ultimate driver of the organizational philosophy - is to Create Value for the Customer.

Defining your purpose is critical for creating direction and alignment in your organization. There are likely hundreds of different things your company wants to accomplish. But a business can't function that way- you can't build strategy around a million different goals and purposes. Instead, you must first define a purpose that sits above all others, and consolidate the rest beneath it. You can then identify the key metrics and identify the projects you're going to work on to improve the strategy and achieve your higher purpose. Everything that doesn't roll up to the defined organizational purpose needs to be deselected to free up resources and energy for achieving the real goal.

"Great leaders aren't defined by what they do, but rather, by what they don't do.

- John Toussaint

What are the behavioral expectations- personal and organizational?

Once you've identified what your purpose is and the principles you'll use to accomplish it, you need to identify what behaviors are necessary in order to make that happen. What are the organizational behaviors you want, and how do those apply to each level of the organization? Each level of the organization has different behavioral expectations. For example, here at KaiNexus, I have seen time and time again with our customers that the success of Lean in an organization depends on who the most senior leader of the organization is, how much they support and value Lean, and what they do to get other people on board to spread Lean and drive change. That person sets the tone and priorities for the entire organization with behavioral expectations that trickle down to all levels.

Without defining the expectations, we really don't know what we're supposed to be doing.

- John Toussaint

It's critical that executives go from understanding theoretically what they're SUPPOSED to be doing to spread Lean and drive results, to ACTUALLY making those behavior changes in their daily work. This often means things like going to the Gemba, engaging with Lean leaders about their projects and results, encouraging the improvement efforts of the front lines, etc.

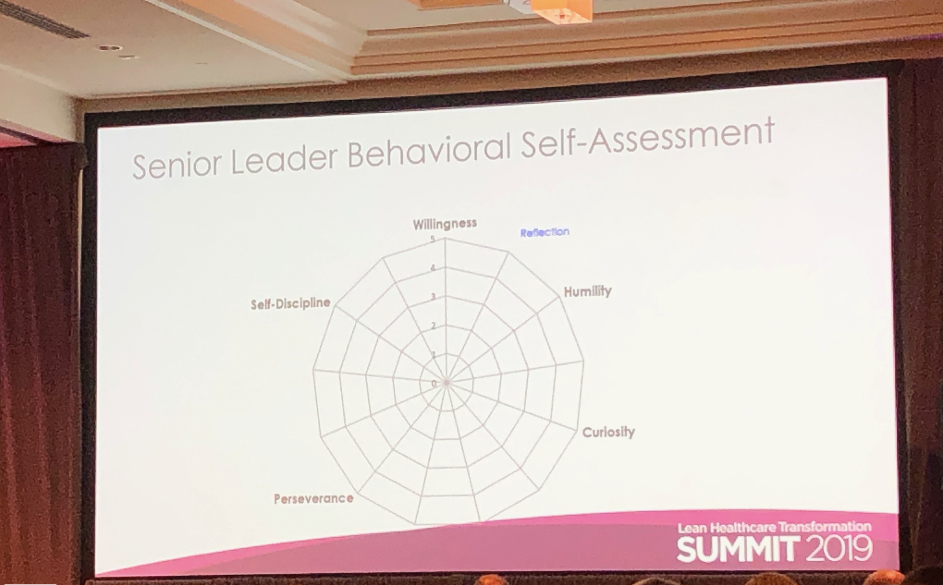

Toussaint suggests this behavioral self-assessment for leaders to evaluate their success in making these changes:

- Willingness to Change. Are you willing to change? Because no one can make you.

- Self Reflection. Do you practice self-reflection? Is it built into your calendar? Ask yourself what releases the creativity of your team, and what shuts them down. Putting it in your calendar makes it a standard practice.

- Humility. Do you practice humility? If so, you're going to see, listen and learn at the Gemba.

- Curiosity. Curiosity is an important factor. Asking open-ended questions, listening deeply to understand. Not the same as listening so you can tell them what to do. A3 thinking - the most effective thing Toussaint has learned as a CEO is to practice A3 thinking.

- Perseverance. Do you have a Lean buddy? Use the partner system. A coach.

- Self-discipline - do you practice leader standard work?

How do you know the model cell is achieving real results?

In a true model cell, you have redefined the work and gotten significant results. That means 50%, 70%, 90% improvement indicating that you've redefined the work, and you're getting to a business model that actually matters. For example, Royal Sussex County Hospital in 2016 was in the lowest 25% of performance in the entire country in several areas. They started down the Lean journey in a couple of specific, preselected units, and then spread lessons learned to the rest of the hospital. They saw dramatic improvements, going from being one of the worst hospitals in the National Health System to one of the best in 18 months using model cell and spread approaches to improving.

What is the strategy for successful financial performance in your market?

You have to make money so that you can stay in business. Lean helps organizations achieve their financial goals in addition to quality goals. For example, working to reduce lab times means you're able to process more patients in a day - which means you make more money, in addition to helping more people, by innovating and thinking differently.

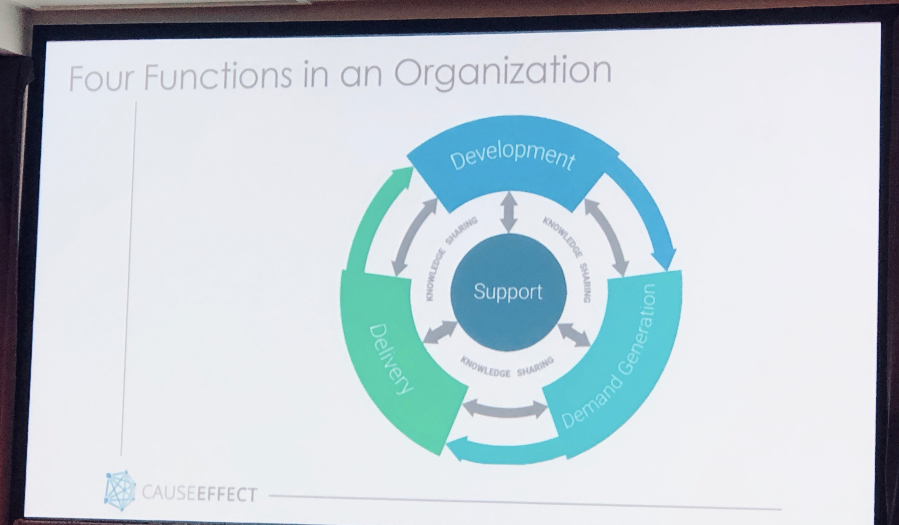

How do you plan to develop new care models?

Improvement in your organization needs to be a standard, consistent, and disciplined process. There must be a structure in place to drive improvement from all levels and ensure that it's all working toward your high-level goals. After all - if your improvement isn't built on process, it's built on luck - and you can't build a company on luck.

![[Watch Now] How to Use A3 Thinking in Everyday Life](https://no-cache.hubspot.com/cta/default/326641/312227ef-895d-48da-b9ee-ee61a5b19930.png)

Add a Comment