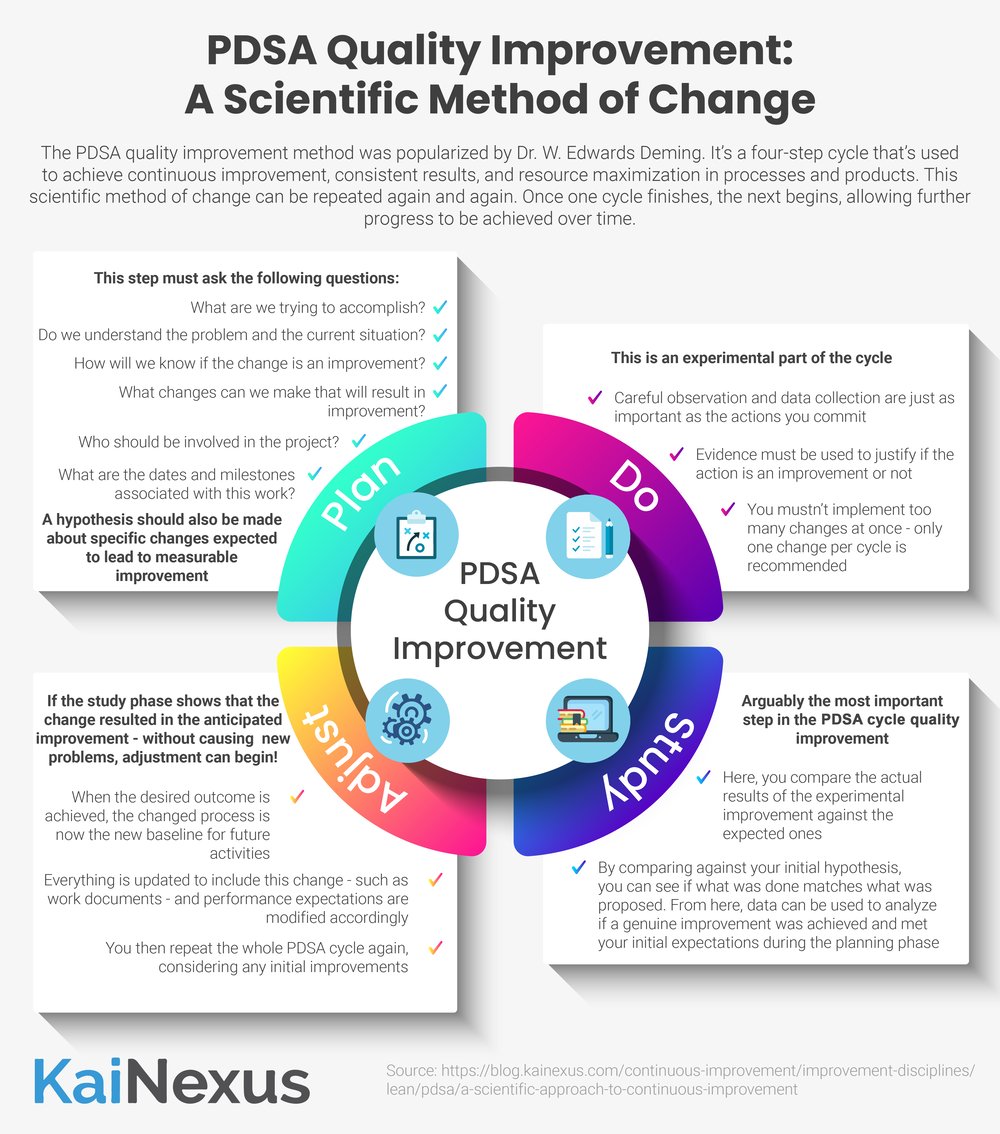

Dr. W. Edwards Deming is considered by many to be the father of modern quality improvement. Among other important insights into how businesses could become more efficient, reduce costs, and increase customer value, he popularized the PDSA quality improvement method. It is a four-step cycle used to achieve continuous improvement, consistent results, and resource maximization in processes and products.

The PDSA cycle of quality improvement, sometimes called the “Deming Cycle,” is based on the scientific method, which approaches problems through hypothesis (plan), experimentation (do), and evaluation (study). In business, the output of a successful PDSA cycle is a new standard work that institutionalizes the improvement. Once complete, the cycle begins again, and further progress can be achieved as processes move ever closer to perfection.

Plan

During the planning phase, it is crucial to not jump to solutions, as people so often tend to do. It's often said that half of the time in a PDSA improvement cycle is spent on "plan," even if it's illustrated as four quadrants of a circle.

Some organizations prefer a formal PDSA charter document to capture and communicate the plan. Others take a more relaxed approach, but in either case, improvement management software is a valuable tool that creates a home for the plan itself and any associated documents, images, diagrams, or other assets.

The planning step must include answers to the following questions:

- What are we trying to accomplish?

- Do we understand the problem and the current situation?

- How will we know if the change is an improvement?

- What changes can we make that will result in improvement?

- Who should be involved in the project?

- What are the dates and milestones associated with this work?

Value stream mapping, fishbone diagrams, and the 5 Whys are helpful improvement techniques to deploy during the planning phase.

Do

Once the planning phase is complete and a hypothesis has been made about specific changes expected to lead to measurable improvement, the “do” step can begin. This part of the cycle should be considered experimental. As with a scientific experiment, careful observation and data collection are just as important as the action itself. We don't want to jump to the conclusion that our action is an improvement if there isn’t substantial evidence for it.

At this stage, it is essential to be careful not to implement multiple changes at once. Doing so will make it difficult to understand the impact of each shift. That’s why the PDSA quality improvement method is so helpful. You can implement one change, understand the results, and then quickly begin again to try a new experiment.

Study

The study step is arguably the most important of the PDSA cycle quality improvement. During this phase, the actual results of the experimental improvement are compared against the expected results. The reality of the implementation is compared against the plan to make sure that what was done matches what was proposed and to make sure that there weren't any unexpected side effects created by the change. The team gathers data and analyzes it to determine if a measurable improvement was achieved and if it meets the expectations defined in the planning phase.

Teams commonly use control charts to visualize the results of the process over time. They can help sort out standard (expected) variation in results from special cause (unexpected) variation.

One thing to note here is that some organizations use the word Check rather than study, so you may find references to the PDCA cycle of quality improvement.

Adjust

If the study phase reveals that the change resulted in the anticipated improvement (without causing any new problems), the adjustment step can begin. If the desired outcome has been achieved, the changed process becomes the new baseline for future activities. Standard work documents are updated to include the change, and performance expectations are modified accordingly. The cycle is then repeated against the new process, and additional improvements are considered.

This is when it is time to communicate the change with all stakeholders and recognize the efforts of those who participated in the work.

As visually represented here, PDSA in quality improvement can be used to identify new standards that constantly improve process results and, therefore, customer value. The guesswork is removed from improvement initiatives, making it easy for organizations to realize the benefits quickly.

Add a Comment