Greg Jacobson

Recent Posts

How Do You Measure the True Impact of Continuous Improvement in Your Organization?

August 1, 2025I've seen countless companies struggle with one fundamental challenge: proving the value of their improvement efforts. Einstein once said,...

5 Principles of a High-Reliability Organization (HRO) — and What CI Leaders Can Learn

February 14, 2026Summary

High-reliability organizations (HROs) operate in high-risk environments yet consistently achieve exceptional safety and...

How CI and OpEx Leaders Use Hoshin Kanri to Drive Organizational Alignment

July 2, 2025We are fortunate enough to get to spend a lot of time chatting with customers and other organizations that are interested in continuous...

What Are the 8 Wastes of Lean and How Can You Eliminate Them?

July 21, 2025Summary

Waste exists in every business, often hidden within daily operations. The 8 wastes of Lean—defects, transportation, waiting,...

Continuous Improvement Leadership Quotes: Inspiring Change and Growth | KaiNexus

February 11, 2025Let’s be honest, it can be difficult to get people excited about the subject of continuous improvement. Of course, we know that continuous...

How to Use the Baldrige Framework to Achieve Performance Excellence

October 31, 2024The urgency to improve organizational performance is at an all-time high. Today’s customers expect more value for every dollar,...

Key Objectives and Activities for Each Step of DMAIC

October 25, 2024DMAIC (Define, Measure, Analyze, Improve, Control) is a data-driven, structured, customer-centric problem-solving methodology. Each phase...

The 7 Steps of Hoshin Kanri (or Hoshin Planning)

October 23, 2024The process you use to develop your strategic plan is as important as the plan itself. Many organizations adopt the Hoshin Kanri method...

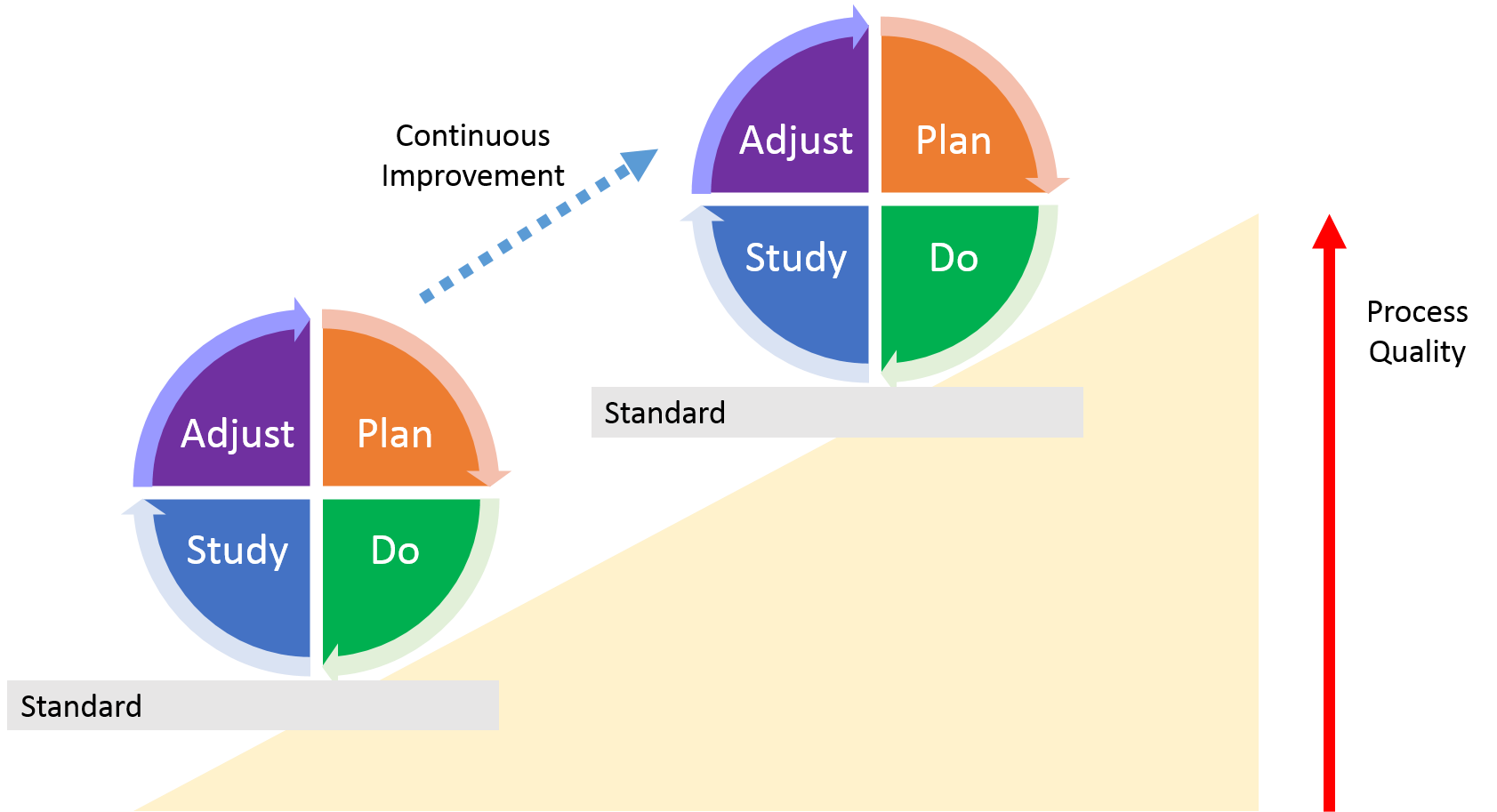

PDSA Quality Improvement: A Scientific Method of Change

July 10, 2024Dr. W. Edwards Deming is considered by many to be the father of modern quality improvement. Among other important insights into how...