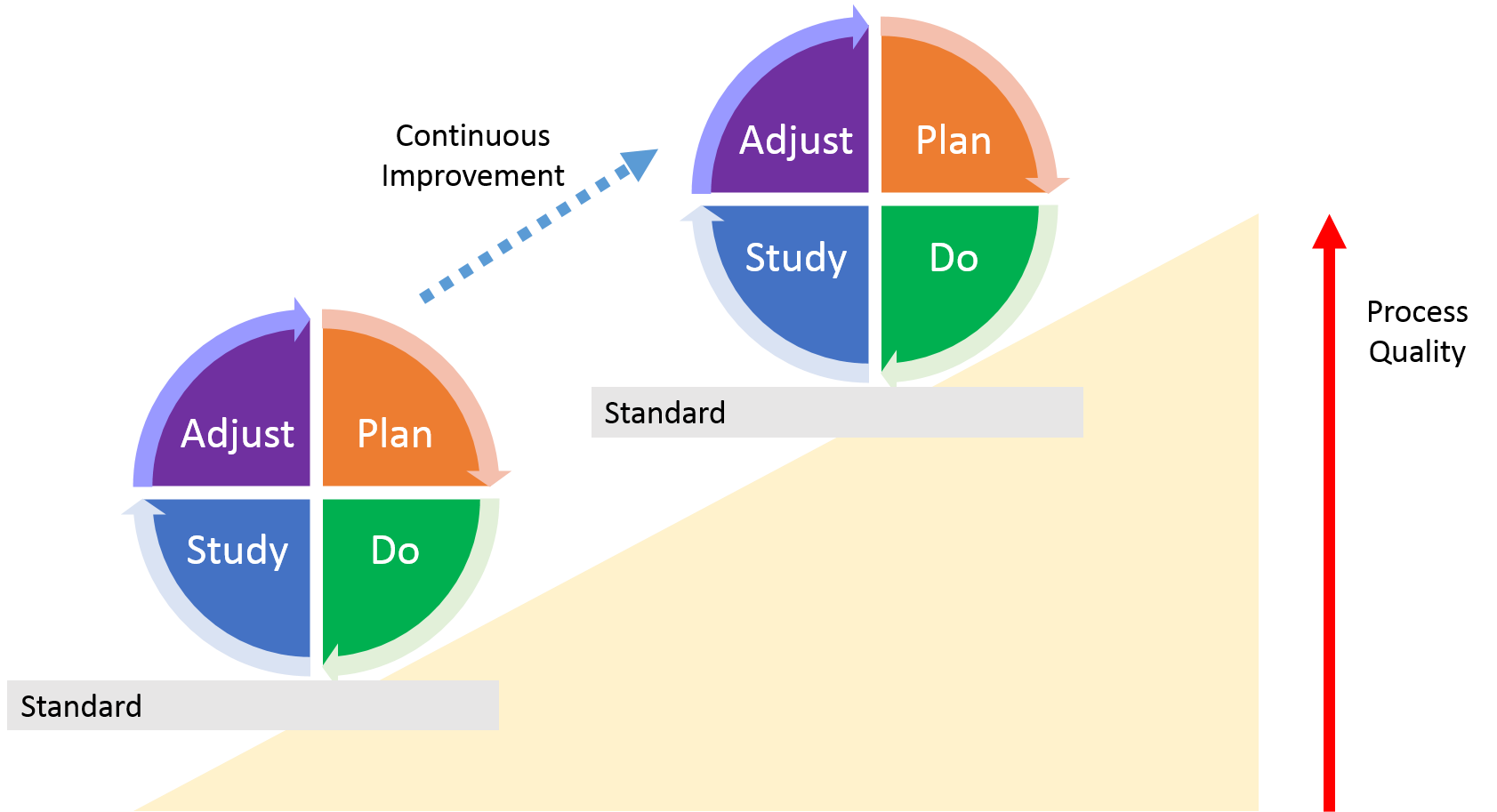

PDSA Quality Improvement: A Scientific Method of Change

July 10, 2024Dr. W. Edwards Deming is considered by many to be the father of modern quality improvement. Among other important insights into how...

9 Easy to Deploy Continuous Quality Improvement Tools

November 24, 2021Quality management programs are often associated with large organizations, such as automotive manufacturing or large healthcare systems....

Value Stream Mapping Best Practices

October 27, 2021Value stream mapping (VSM) is used to visually depict, analyze, and improve the flow of materials and information through end-to-end...

5 Ways To Accelerate The Pace of Change

August 25, 2022McKinsey and Company, one of the country’s leading management consultancies, reports that up to 70% of systemic change programs fail to...

The Connection Between Trust and a Culture of Change

July 29, 2020Humans are hard-wired for change. As soon as we are born, we start to grow, learn, and adapt to our environment. If that's the case, why is...

Change Management Tips for Leaders

July 21, 2020People react very positively to the concept of continuous improvement. They are a little less enthusiastic when it is framed as constant...

4 Ways to Overcome Resistance to Change

June 9, 2020When you ask people if they would like to be involved in continuous improvement, they are likely to say, “Of course!” But ask them if they...

How Change Management Software Promotes Innovation

March 4, 2019Agility is perhaps one of the most essential qualities of successful modern companies. The ability to adapt to changing marketing...

Looking for the Best Change Management Software? Here’s Your Guide.

December 28, 2018Whenever I think about the process of buying software two quotes, come to mind. The first is, “You don’t know what you don’t know.” The...