What Are the Most Effective Lean Six Sigma Tools for Process Improvement?

February 3, 2026Lean Six Sigma combines Lean’s system-wide approach to improving flow and quality with Six Sigma’s analytical tools for understanding...

Key Objectives and Activities for Each Step of DMAIC

October 25, 2024DMAIC (Define, Measure, Analyze, Improve, Control) is a data-driven, structured, customer-centric problem-solving methodology. Each phase...

12 Workplace Organization Techniques & Management Tools

August 30, 2024Six Sigma and Lean manufacturing are business methodologies focused on improving the quality of goods or services an organization produces...

DMAIC: Framework and Approach to Continuous Improvement

January 19, 2024Continuous improvement is a systematic and ongoing process to enhance the efficiency, effectiveness, and overall performance of an...

The Ultimate Guide to Process Improvement Methodologies For Increased Productivity

September 14, 2023According to a study conducted by the International Quality and Productivity Center (IQPC), businesses that prioritize process improvement...

Continuous Improvement vs Lean: What's the Difference?

August 11, 2023We, at KaiNexus, are fortunate to have the opportunity to chat with business leaders across the spectrum about the challenges and...

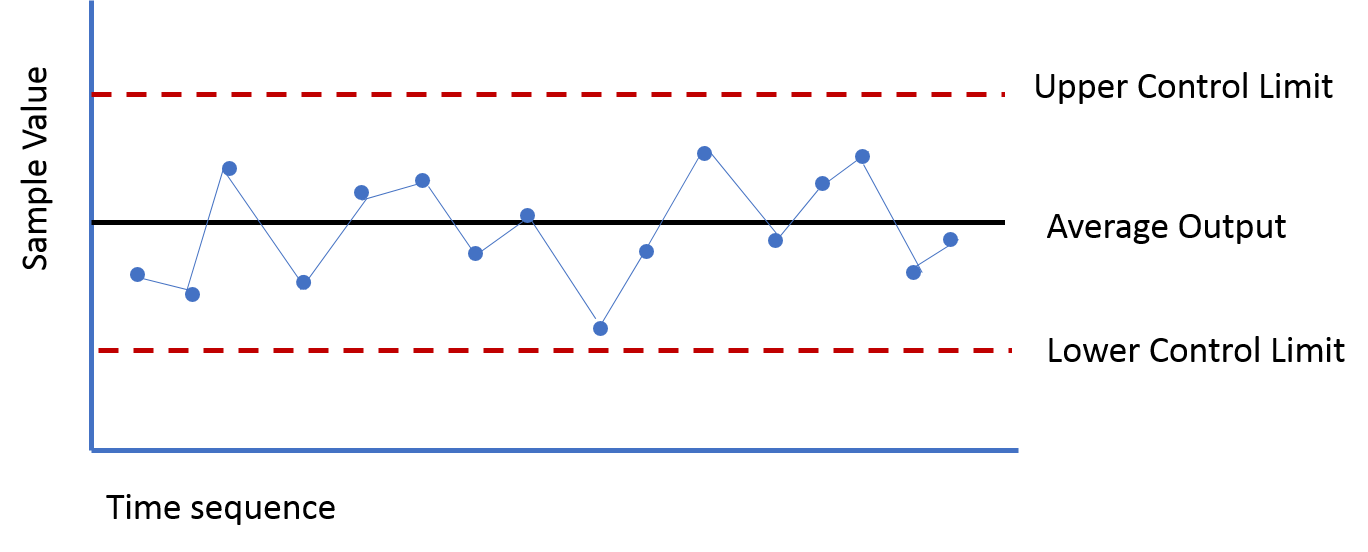

An Introduction to Process Behavior Charts

December 18, 2025Donald J. Wheeler, Ph.D. is a world-renowned expert in statistical methods and continuous improvement. He's worked with W. Edwards Deming...

Six Sigma FAQ: Which Tools are Commonly Used for DMAIC?

September 21, 2022The Six Sigma business methodology aims to eliminate waste and defects. It also aims to reduce variation in business processes. Efforts to...

DMAIC Tools Offer a Solid Structure for Problem Solving

August 25, 2022DMAIC (Deh-May-Ick) tools are some of the most critical options in the continuous improvement toolbox. They are most closely associated...