What Are the Most Effective Lean Six Sigma Tools for Process Improvement?

February 3, 2026Lean Six Sigma combines Lean’s system-wide approach to improving flow and quality with Six Sigma’s analytical tools for understanding...

9 Continuous Improvement Methodologies to Enhance Your Improvement Program

June 7, 2024Organizations that embrace the continuous improvement approach to business have many great tools and techniques from which to choose. Some...

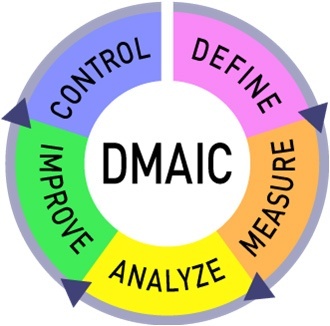

DMAIC: Framework and Approach to Continuous Improvement

January 19, 2024Continuous improvement is a systematic and ongoing process to enhance the efficiency, effectiveness, and overall performance of an...

Unlocking Success with the DMAIC Model: Your Essential Guide

October 24, 2023DMAIC is a structured, customer-focused, data-driven approach to problem-solving. The acronym stands for:

1- Define

2- Measure

3- Analyze

...

Continuous Improvement Tools, Techniques, and Why You Need Them

July 17, 2023Continuous improvement is an ongoing effort to enhance processes, products, services, and overall business performance. It is a systematic...

Business Process Improvement (BPI): The Complete Guide to Methods, Tools, and Examples

February 14, 2026Business process improvement (BPI) is the systematic approach of analyzing, optimizing, and enhancing existing business processes to...

Top 15 Process Improvement Tools to Enhance Workflow Performance

July 13, 2023Organizations implement process improvement initiatives, using various process improvement tools, to drive operational excellence, enhance...

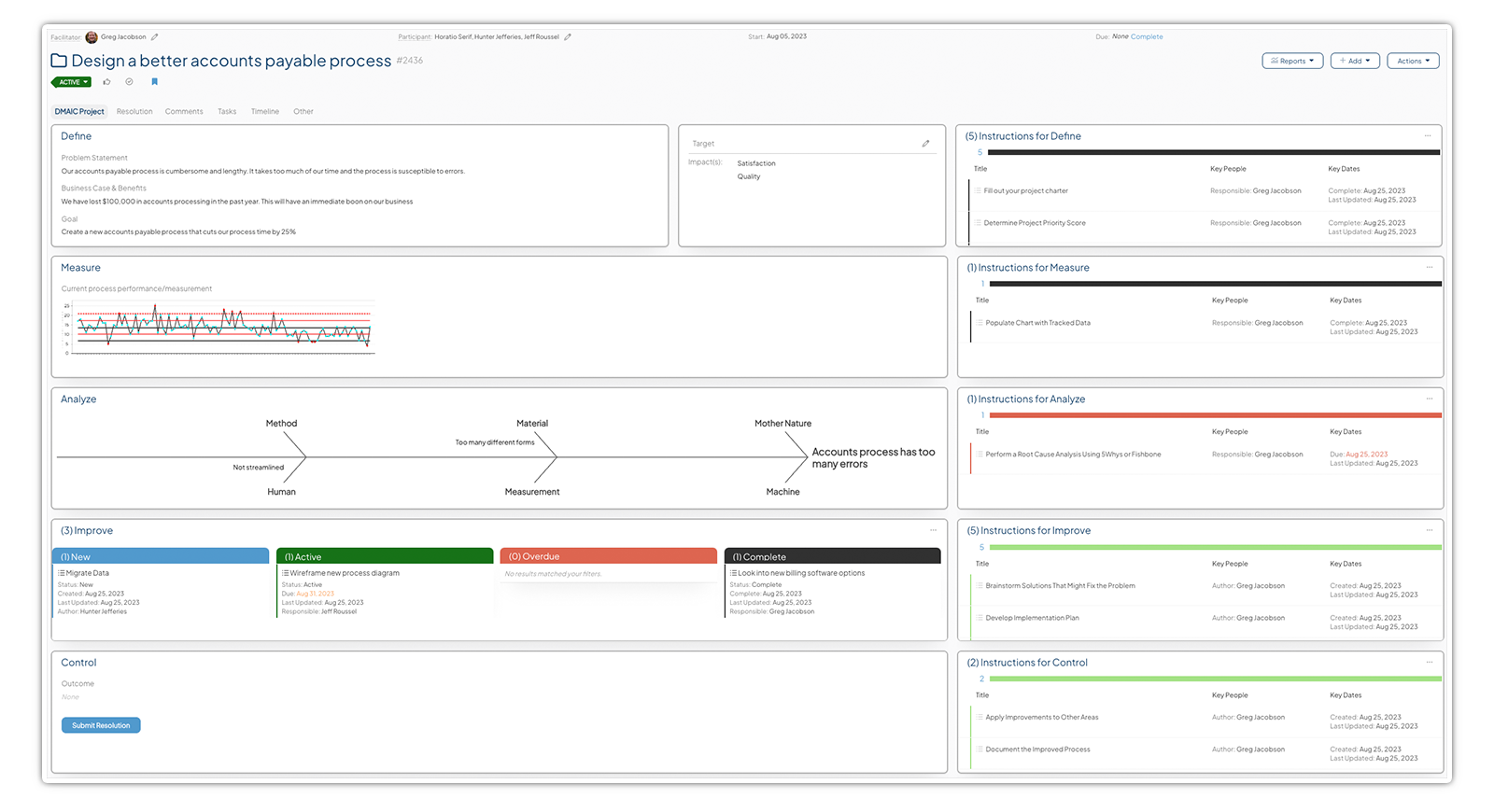

DMAIC Tools Offer a Solid Structure for Problem Solving

August 25, 2022DMAIC (Deh-May-Ick) tools are some of the most critical options in the continuous improvement toolbox. They are most closely associated...

How to Effectively Define Your Six Sigma Project Scope

July 5, 2022Lean Six Sigma is a business optimization methodology that combines two popular continuous improvement methods, Lean and Six Sigma. These...