What Are the Most Effective Lean Six Sigma Tools for Process Improvement?

February 3, 2026Lean Six Sigma combines Lean’s system-wide approach to improving flow and quality with Six Sigma’s analytical tools for understanding...

Top 15 Process Improvement Tools to Enhance Workflow Performance

July 13, 2023Organizations implement process improvement initiatives, using various process improvement tools, to drive operational excellence, enhance...

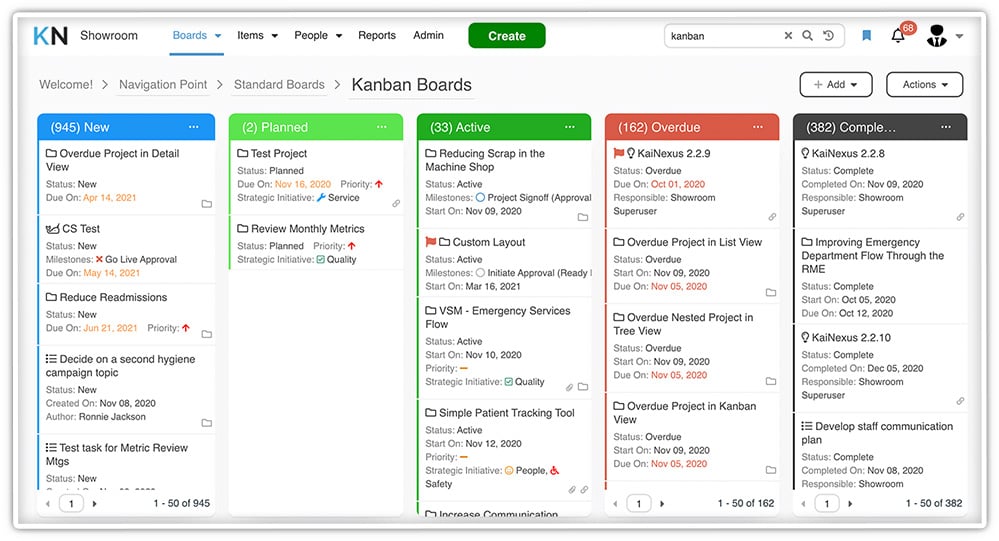

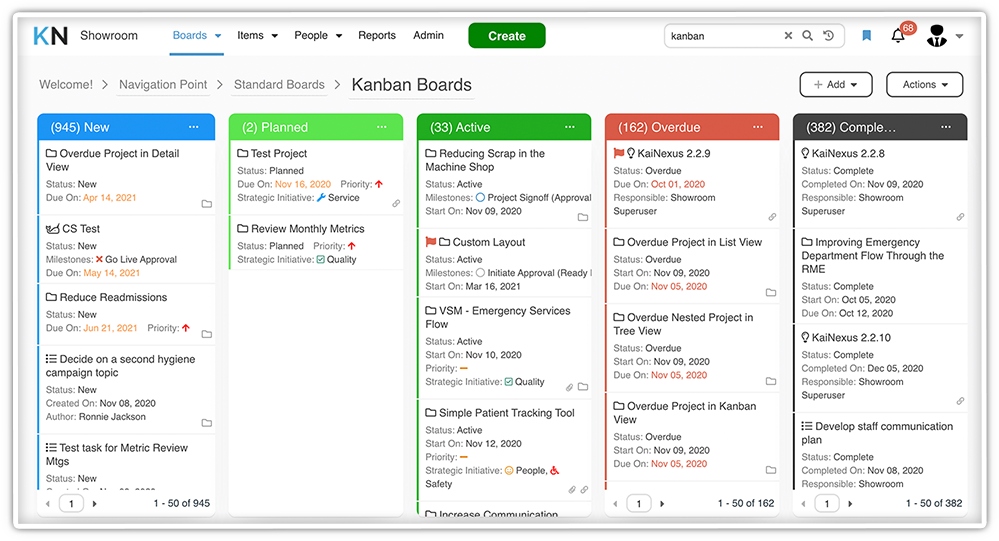

What is a Kanban Board and How Does it Improve Quality?

June 22, 2023In the post-WW II era, Toyota realized that they could improve profitability and product quality by matching parts inventory with real-time...

The Agile Project Management Approach to Value Delivery

March 1, 2022Agile project management is an iterative philosophy that focuses on delivering value frequently and getting quick feedback from internal...

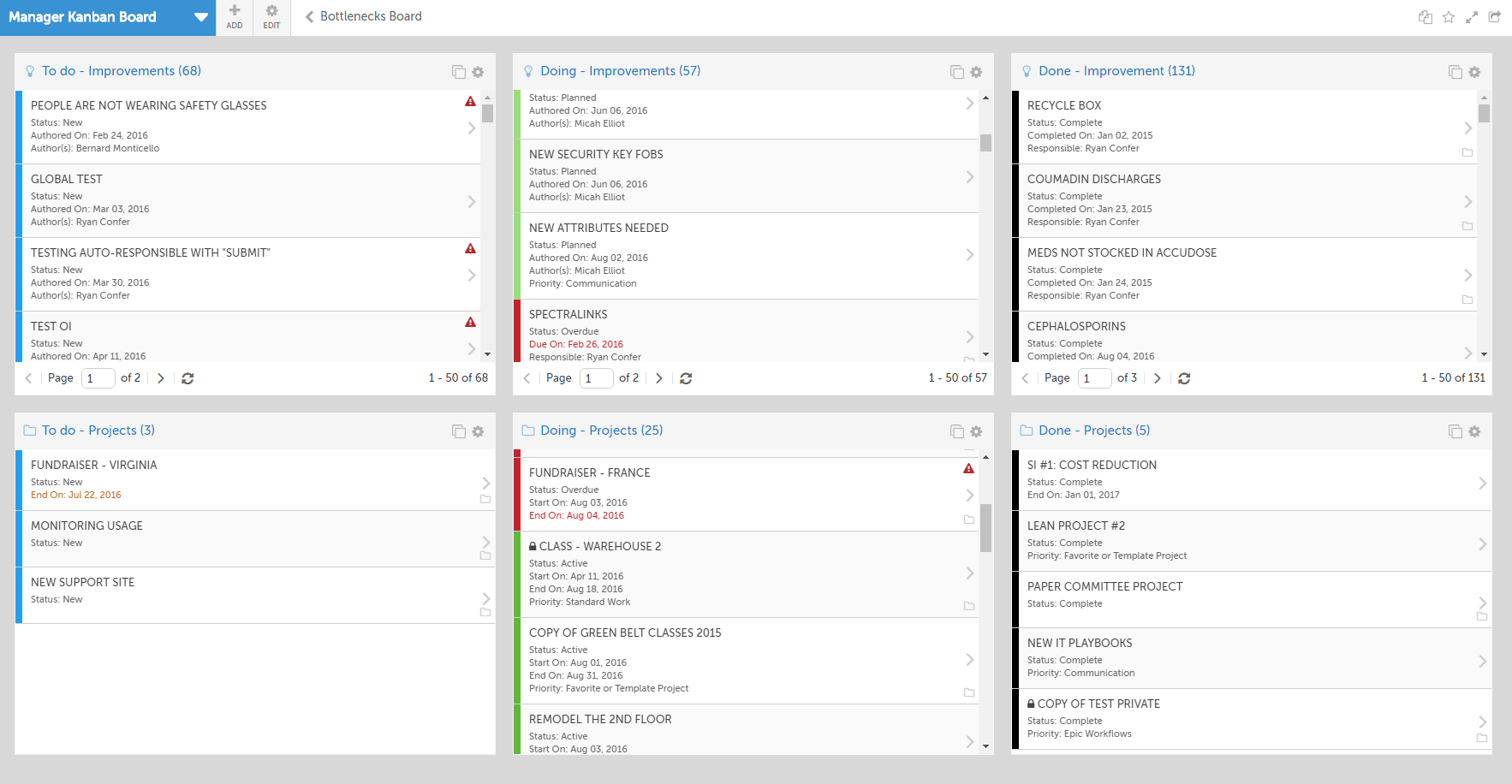

Before You Build a Kanban Excel Template, Consider This

May 24, 2021The internet is full of free Kanban Excel templates that you can download. That’s not surprising because the format of a Kanban board can...

8 Ways Kanban Board Software Changes the Game

May 28, 2019Kanban boards are excellent visual management tools for tracking work-in-progress, identifying roadblocks, and ensuring a free-flowing...

9 Reasons to Consider a Digital Kanban Management Tool

January 9, 2019As you might expect, we write quite a bit about Lean and Six Sigma management techniques that have been modernized by moving to digital...

The Best Alternative to a Kanban Board in Excel

August 16, 2018Microsoft Excel is one of the most widely used applications on the planet. I know exactly why. It’s amazingly flexible, most people know...

7 Reasons to Consider Kanban Software

August 2, 2018The Kanban visual management technique has been around since the late 1940’s when Toyota introduced it in its manufacturing plants. They...

/Boards/Board%20Designs/Kanban%20Board/Kanban%20Board%20One%20Card.png)