DMAIC (Deh-May-Ick) tools are some of the most critical options in the continuous improvement toolbox. They are most closely associated with the Six Sigma methodology. Still, the DMAIC approach to problem-solving is also used by those who practice Lean manufacturing or don’t use a formal management structure. DMAIC is so widely used because the problem-solving framework takes teams from discovering root causes to long-term, stable standard work. It is a repeatable process that employees can learn to apply to any number of process problems.

What Are DMAIC Tools?

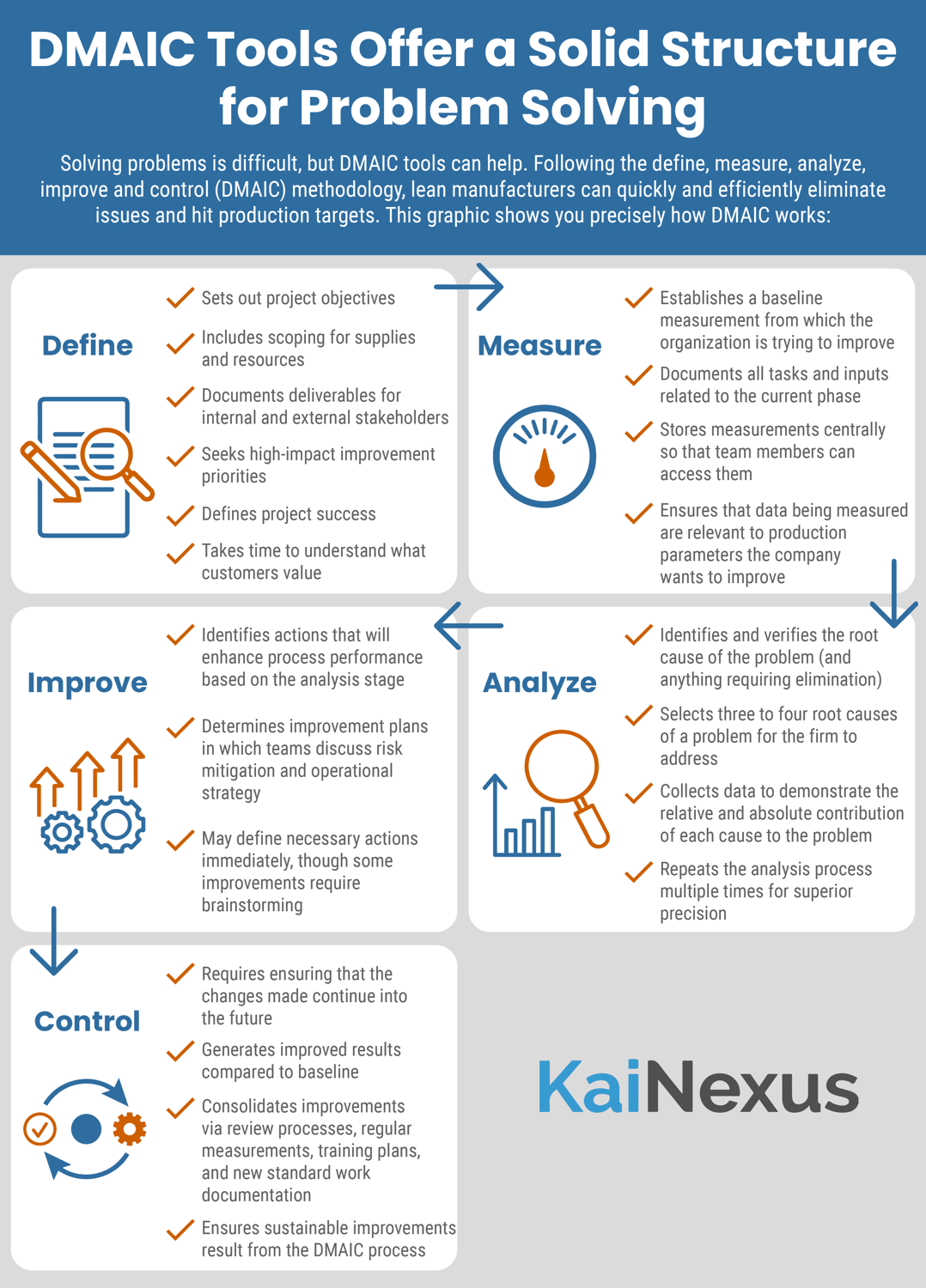

DMAIC stands for Define, Measure, Analyze, Improve, and Control. Motorola is credited with bringing it to prominence, although it was essentially an evolution of the Toyota production system.

A deeper dive reveals why it works so well.

Define

Interestingly enough, “Define” was not part of the original cycle deployed by Motorola in the 1980s. It was later added when IBM adopted the Six Sigma methodology. IBM wanted to emphasize the need to scope and supply resources for every improvement project, and that’s exactly what happens during the “Define” step when DMAIC is deployed today.

In this first step of the cycle, project objectives and deliverables are documented for both internal and external customers of the process. Teams look for high-impact improvement priorities and decide on the definition of success. Great care is taken to understand the customers and their requirements. The group discusses what adds value to the customer and what their expectations are. It is often also useful to define what is outside of the scope of the project.

DMAIC tools at this stage typically include the project charter, process flowchart, and stakeholder analysis.

Measure

Regardless of which improvement technique you use, a baseline upon which to improve is essential. Without understanding the results of the process in place today, you can never know if you’ve achieved improvement. That’s where the “Measure” step comes in. During this phase, the current process and all related tasks and inputs are documented. Contemporary forms of measurement are validated, and a baseline performance value is obtained. Ideally, the measurement data is centrally stored to be easily accessible to the team working on the project and any other stakeholders. Team members should make sure that the measurements get at the heart of the issue, rather than the easiest things to measure.

Tools typically include a data collection plan, sigma calculation, and benchmarking.

Analyze

This step aims to identify, verify, and select the root cause of the problem for elimination. If the analysis reveals too many root causes, the “Define” step may not have been specific enough. Generally, 3-4 root causes are selected, and a plan is crafted to collect data to prove the relative contribution of each root cause to project metrics. The process may need to be repeated multiple times until the culpable root causes are identified.

DMAIC tools used now often include the five whys, fishbone diagrams, and regression analysis.

Improve

Once the root causes are clear, the team can identify the improvements that will lead to better process performance. Sometimes the best solution will be immediately apparent, but often a great deal of brainstorming and innovation is required. At this stage, the team determines the improvement plan, discusses risks and mitigation tactics, and prepares to measure results based on the predefined KPIs.

DMAIC problem-solving tools used in the Improve phase include brainstorming, mistake proofing (Poka-yoke), and improvement management technology.

Control

Once improvements are in place and proven to have positive results, the object becomes the new, more effective state and is maintained over time. The changes that were made must be held constant to ensure the same results. This generally involves creating new standard work documentation, crafting a training plan, and setting up regular measurement and review processes. Unfortunately, this is a frequently neglected part of the DMAIC problem-solving cycle, which is why many organizations see short-term gains from improvement projects but don’t enjoy lasting results. Improvement management software with notifications and alerts can help ensure that gains are maintained over time.

Typical tools include standard work, process control charts, and project management software.

The DMAIC cycle can be quick and easy for simple problems with clear root causes, or it can involve many improvement tools and cross-functional collaboration for more difficult challenges. In either case, it requires discipline and attention to detail, two essential elements of continuous.

Add a Comment