Lean continuous improvement is a systematic approach to perfecting business processes and operations by eliminating waste, increasing efficiency, and delivering more value to customers. The "lean" philosophy emphasizes eliminating non-value-added activities and processes to create more value with fewer resources.

Lean continuous improvement is a systematic approach to perfecting business processes and operations by eliminating waste, increasing efficiency, and delivering more value to customers. The "lean" philosophy emphasizes eliminating non-value-added activities and processes to create more value with fewer resources.

Lean is built on best practices for continuous improvement, including employee engagement and focusing on creating a culture that supports positive change.

What is continuous improvement?

Continuous improvement is an ongoing effort to improve business processes and operations incrementally by identifying and addressing inefficiencies and waste. This involves collecting data, analyzing it, and implementing changes to improve the process.

Continuous improvement is critical to many management philosophies, including Total Quality Management (TQM), Six Sigma, and Lean Manufacturing. While lean was developed to improve manufacturing processes, today, it is widely used in various industries. There are also specific tools that support continuous improvement for healthcare.

It is important to note that continuous improvement is a bottom-up approach to change. The role of leadership is to support lean thinking and provide resources for improvement. The mid-level and front-line employees identify opportunities to improve and use lean tools to implement solutions that address the root causes of problems.

What is lean manufacturing?

Many people associate lean tools with the manufacturing industry. That's because the principles of lean were initially developed by Toyota in the 1950s and are based on continuous improvement and respect for people.

Other companies built on Toyota's success and implemented lean manufacturing principles include Ford, Boeing, Caterpillar, Intel, and Nike.

While lean was developed to improve manufacturing processes, it is widely used in various industries, notably healthcare, software development, construction, education, financial services, mining, and food and beverage.

11 best lean continuous improvement tools

Over time, organizations have developed lean continuous improvement tools to standardize improvement and create a consistent language around incremental change. Every organization is unique, so the mix of process improvement tools varies, but eleven stand out as fundamental to the lean tools list.

Kaizen

Kaizen is a Japanese word that translates to "continuous improvement" or "good change" in English. It is a philosophy and methodology for improving processes and systems by making small, incremental changes over time. Kaizen aims to empower employees to optimize efficiency, eliminate waste, and improve quality in all aspects of a business.

Kaizen originated in Japan after World War II and became popularized by Japanese manufacturers, such as Toyota, in the 1950s and 1960s. The methodology involves identifying areas for improvement, developing a plan to make changes, implementing those changes, and then continuously evaluating and refining the process to achieve even better results.

Examples of Kaizen include,

- A customer service team analyzes their call handling process and identifies opportunities for improvement.

- A restaurant uses customer feedback to make small improvements to its menu and service.

- A software development team uses lean methodologies to identify areas for improvement and make small changes to optimize their workflow and improve the quality of their code.

5S

The 5S workplace methodology organizes and optimizes the workplace to improve efficiency and reduce waste. The 5S's stand for Sort, Set in order, Shine, Standardize, and Sustain.

Sort: This involves considering all items in a workspace and separating them into what is necessary and what is unnecessary. Unnecessary items are either disposed of or removed from the workspace.

Set in order: This step involves arranging the necessary items logically and efficiently so they are easily accessible and easy to find.

Shine: This involves thoroughly cleaning and inspecting the workspace to maintain cleanliness and identify potential problems or areas for improvement.

Standardize: This step involves creating standardized procedures and guidelines for maintaining the first three S's so that they become part of the regular work routine.

Sustain: This step involves continuously monitoring and improving the first four S's to ensure they are consistently applied and maintained over time.

5S has applications for workers in all industries, from factory floors to offices for information workers. A few examples include:

- Removing infrequently used tools and equipment from a manufacturing plant.

- Digitizing, archiving, and organizing paper files and folders.

- Labeling equipment and tools as well as their storage spaces.

- Centralizing the location of shared office equipment such as copiers and printers.

Value Stream Mapping (VSM)

Value stream mapping is a popular lean manufacturing tool used to analyze the flow of materials and information required to produce a product or service from start to finish. The object of value stream mapping is to identify opportunities for improvement in the value stream and to eliminate waste in the process.

The value stream map shows all of the steps in the process, including the inputs, outputs, and cycle times for each step. It also includes inventory levels, lead times, and key performance indicators (KPIs) for each step.

Once the value stream map of the current state is created, the organization can use it to identify opportunities for improvement. For example, they may identify steps taking longer than necessary or those that create excess inventory. They can then develop and implement a plan to streamline the process, reduce cycle times, and eliminate waste.

Poka-Yoke (Error Proofing)

Poka-yoke is a Japanese term that means "mistake-proofing" or "error-proofing." The goal is to identify and eliminate potential errors before they occur by designing systems or processes that make mistakes impossible.

There are three types of poka-yoke opportunities:

Contact methods: These devices prevent errors by detecting abnormalities or deviations in the process. For example, a machine may have sensors that detect when a part is out of place and stop the machine before it can cause a problem.

Fixed-value methods: These are systems or processes designed with fixed values or constraints that prevent errors from occurring. For example, a software program may have validation rules that prevent users from entering a phone number with too few characters or an incorrectly formatted email address.

Motion-step methods: These tools use the operator's body to detect and prevent errors. For example, a machine operator may be required to use two hands to activate a control button, ensuring they cannot accidentally activate the button while their hands are in a dangerous position.

By preventing mistakes from occurring, poka-yoke reduces costs, improves quality, and increases customer satisfaction.

Kanban

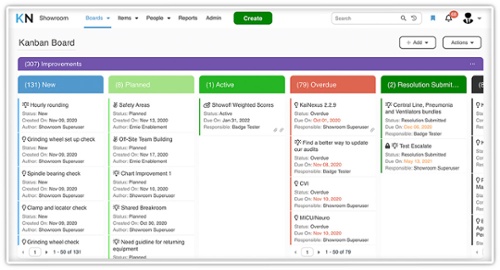

Kanban is a lean continuous improvement tool to manage and control inventory levels, production flow, and work-in-progress.

The Kanban system uses visual signals, such as cards or boards, to indicate inventory and production status. These visual signals are used to trigger the production or replenishment of inventory as needed, ensuring that suitable materials are available at the right time. Today, many organizations use digital Kanban boards to visualize work-in-progress.

Kanban supports the lean principles of flow and pull. When work-in-progress is apparent, workers can create exactly and only what is needed by the next step in the process, eliminating bottlenecks and backlogs. For example, software development teams can focus on areas where the QA team can test the improved version.

Plan-Do-Check-Act (PDCA)

Plan-Do-Check-Act (PDCA) is a four-step iterative management method used in business to control and continuously improve processes and products. It is also called the Deming Cycle, after W. Edwards Deming, who popularized its use as a continuous improvement tool in quality management.

The four steps of PDCA are:

Plan: Define the problem or opportunity for improvement, establish objectives, and develop a plan to achieve those objectives.

Do: Implement the changes and collect data on the results. This may involve testing, piloting, or implementing the plan on a small scale.

Check: Analyze the data collected in the "do" stage to determine whether the plan successfully achieved its objectives.

Act: Take action based on the analysis of the "check" stage. If the plan is successful, you may implement it on a larger scale. If not, you may revise the plan and repeat the cycle.

Using PDCA, organizations can identify and correct problems, improve processes, and achieve better results.

Root Cause Analysis (The 5 Whys)

The 5 Whys is a problem-solving technique used to support root cause analysis. It is a simple but powerful method that involves asking "why?" five times to uncover the underlying cause of a problem.

The process of the 5 Whys typically involves the following steps:

Identify the problem: Start by defining the problem or issue that needs to be addressed.

Ask "why?" five times: Ask "why?" five times to identify the root cause of the problem. Each "why?" question should lead to a deeper understanding of the problem and the underlying cause.

Identify the root cause: After asking "why?" five times, you should have identified the root cause of the problem.

Develop a solution: Once you have identified the root cause, you can develop a solution to address the problem.

Organizations can use the 5 Whys to improve their processes, reduce waste, and improve overall performance.

Standardized Work

Standardized work is a documented and agreed-upon set of procedures or processes that define the best way to perform a particular task or activity. It is a critical component of lean manufacturing and other continuous improvement methodologies, as it provides a baseline for consistent performance and helps identify improvement opportunities.

The standard is developed by the people who operate the process. It is available where work is done and is only changed following a structured improvement cycle such as PDCA.

Standardized work typically includes the following components:

The sequence of steps: A precise, step-by-step series of actions that must be followed to complete the task or activity.

Time required: An estimated or actual time required to complete each step in the sequence.

Quality standards: The specific quality standards or metrics that must be met for the task or activity to be considered complete.

Training requirements: Any training or qualifications required to perform the task or activity.

By documenting and consistently following standard work procedures, organizations can improve quality, reduce errors and defects, increase efficiency, and reduce waste.

Gemba Walks

A Gemba walk is a lean continuous improvement tool that involves going to the "Gemba," which is the place where work is being done, to observe and understand the work processes and identify opportunities for improvement.

During a Gemba walk, a manager or team leader will visit the work area and observe the processes, asking questions and listening to employee feedback. Leaders don't implement change during the Gemba walk. Instead, they collect information and input and use it to guide an improvement cycle.

By engaging in Gemba walks, organizations can foster a culture of continuous improvement and create a shared understanding of the work being done.

Muda, Mura, and Muri (The 3Ms)

These three Japanese terms come from the Toyota Production System — a method for the elimination of waste within a manufacturing system — and collectively describe wasteful practices to be eliminated. Collectively, muda, mura, and muri are sometimes referred to as “the 3Ms of Lean.”

- Muda: Muda is anything that consumes resources without creating value for the customer. The 7 wastes of Lean are all forms of Muda. The seven wastes include motion, inventory, waiting, defects, overproduction, transportation, and overprocessing, but some add additional categories like talent, resources, and by-products. Sometimes, an 8th type of waste is added - the waste of talent or human potential.

- Mura: Mura is an imbalance or inconsistency in operation. While the seven (or eight) wastes are usually part of everyone’s introduction to Lean, not everyone is familiar with mura, which is an unfortunate oversight, as unevenness in operation puts unfair demands on processes and people, which then leads to the creation of muda.

- Muri: Muri is the overburdening of equipment, employees, or processes by requiring them to operate too fast, with too much effort, or for longer than equipment designs and good workforce management allow. Like mura, muri can also lead to the seven wastes of muda.

Six Sigma

Six Sigma is a methodology for improving business processes and reducing defects and variability in products and services. It is a data-driven approach that seeks to identify and eliminate the causes of errors and imperfections to achieve near-perfect quality.

The term "six sigma" refers to the statistical measurement of variability to reduce defects to less than 3.4 per million opportunities. This is achieved through a structured problem-solving process called DMAIC, which stands for Define, Measure, Analyze, Improve, and Control.

Six Sigma is typically implemented by trained professionals called Green Belts and Black Belts, who work on Six Sigma projects as part of their job responsibilities. The methodology has been used successfully in many industries, including manufacturing, healthcare, and service, to improve quality, reduce costs, and increase customer satisfaction.

The Principles of Lean Management

Lean management principles are based on the Toyota Production System and focus on continuous improvement, waste reduction, and creating value for the customer. The five core principles of lean management are:

Identify value

Identify the value customers are willing to pay for and focus on delivering that value while eliminating activities that do not add value.

Value stream mapping

Map out the entire value stream and eliminate activities that do not add value, including waste, delays, and defects.

Create a continuous workflow

Create a continuous flow of work that is smooth and uninterrupted, with minimal delays and inventory.

Establish a pull system

Create a pull system where work is produced in response to customer demand rather than being pushed through production.

Facilitate continuous improvement

Continuously improve processes and systems to eliminate waste, improve quality, and reduce costs.

These principles are supported by the 11 lean continuous improvement tools we've mentioned. By implementing these principles and practices, organizations can reduce waste, improve quality, and increase efficiency, resulting in higher customer satisfaction and improved profitability.

How KaiNexus Can Help

KaiNexus is a platform designed to help organizations implement and manage continuous improvement initiatives, including lean, Six Sigma, and other improvement methodologies. In addition, KaiNexus provides a central location for teams to collaborate on improvement projects, track progress, and share results.

With KaiNexus, leaders can engage more people in improvement, measure the health of lean culture, and understand the impact of improvement work. Organizations enjoy an accelerated rate of positive change by streamlining lean continuous improvement tools and projects in a unified platform. Our customer success experts know how to customize the solution for optimal results.

The advantages of lean continuous improvement include increased efficiency, reduced waste and costs, improved quality, and increased customer satisfaction. It is a powerful approach for organizations that want to stay competitive and adapt to changing market conditions. Contact us today for more information about how KaiNexus has helped customers implement these and other lean management tools.

Add a Comment