Although the Lean quality improvement methodology was initially developed to improve the quality and productivity of automotive factories, it has been used with great success in industries and settings of all types, including software development, government, retail, and other service settings.

Healthcare organizations, in particular, have found that the approach can be used to reduce costs and improve the quality of care, patient safety, and satisfaction at the same time.

What is Lean Healthcare?

Lean healthcare is a management system and way of thinking that helps healthcare organizations continuously improve patient care, safety, quality, and staff engagement—at the same time. This all leads to lower cost, as the end result of doing everything else well.

While Lean methods were first developed in manufacturing, their application in healthcare has never been about treating patients like products. As I explain in Lean Hospitals, Lean in healthcare is fundamentally about designing better systems of care so that clinicians and staff can reliably do the right thing for patients—without workarounds, heroics, or burnout.

At its core, Lean healthcare involves:

-

Studying how care is actually delivered (not how we think it’s delivered)

-

Identifying barriers, frustrations, delays, and risks embedded in processes

-

Redesigning systems so that quality and safety are built in, not inspected in later

A common misconception is that Lean is mainly about cutting costs or working faster. In reality, the most successful Lean healthcare organizations focus first on patient safety, flow, and staff well-being. Cost improvements follow as a result of better processes—not as the primary goal.

Another defining characteristic of Lean healthcare is who leads improvement.

In Healthcare Kaizen, my co-author Joe Swartz and I emphasize that the people who do the work—nurses, physicians, medical assistants, pharmacists, schedulers, and support staff—are best positioned to improve it. Lean healthcare creates systems that:

-

Make problems visible

-

Encourage people to speak up

-

Support small, rapid improvements every day (Kaizen), not just large projects

This requires a shift in leadership mindset. Instead of directing solutions from above, leaders are responsible for:

-

Creating psychological safety

-

Coaching problem solving

-

Removing barriers that frontline teams cannot fix on their own

When practiced well, Lean healthcare aligns everyone around a shared purpose: delivering better care for patients while making healthcare a better place to work.

Lean Healthcare: More Than a Cost-Cutting Exercise

Lean healthcare focuses on understanding care delivery as a system, not a series of isolated tasks. Every patient journey—whether a clinic visit, an inpatient stay, or a virtual encounter—crosses multiple handoffs, roles, and departments. Problems rarely originate with individuals; they emerge from how the system is designed and managed.

In my book Lean Hospitals, I describe Lean as a way to:

-

Improve patient safety and clinical outcomes

-

Reduce frustration and burnout for staff

-

Eliminate delays and rework that harm patients

-

Create better places to work and receive care

Lean asks a simple but powerful question:

“What makes it hard for people to do the right thing for patients?”

What Lean Healthcare Really Emphasizes

Lean healthcare succeeds when leaders focus on these interconnected principles:

Continuous Improvement as Daily Work

Improvement is not an occasional project or a consultant-led event. It’s something that happens every day, in small ways, led by the people who know the work best.

Value Defined by the Patient

Value isn’t what we measure internally—it’s what helps patients achieve better health, with less waiting, confusion, and harm.

Respect for People

Respect means more than being polite. It means:

-

Listening seriously to concerns and ideas

-

Designing systems that make work easier, not harder

-

Treating mistakes as opportunities to improve processes, not to blame individuals

Visual Management and Transparency

Simple visual systems help teams see problems early, discuss them openly, and learn together—without fear.

Root Cause Problem Solving

Rather than asking “Who made the mistake?”, Lean organizations ask:

“Why did the system allow this to happen—and how can we redesign it?”

Eliminating Waste in Healthcare—Without Losing Compassion

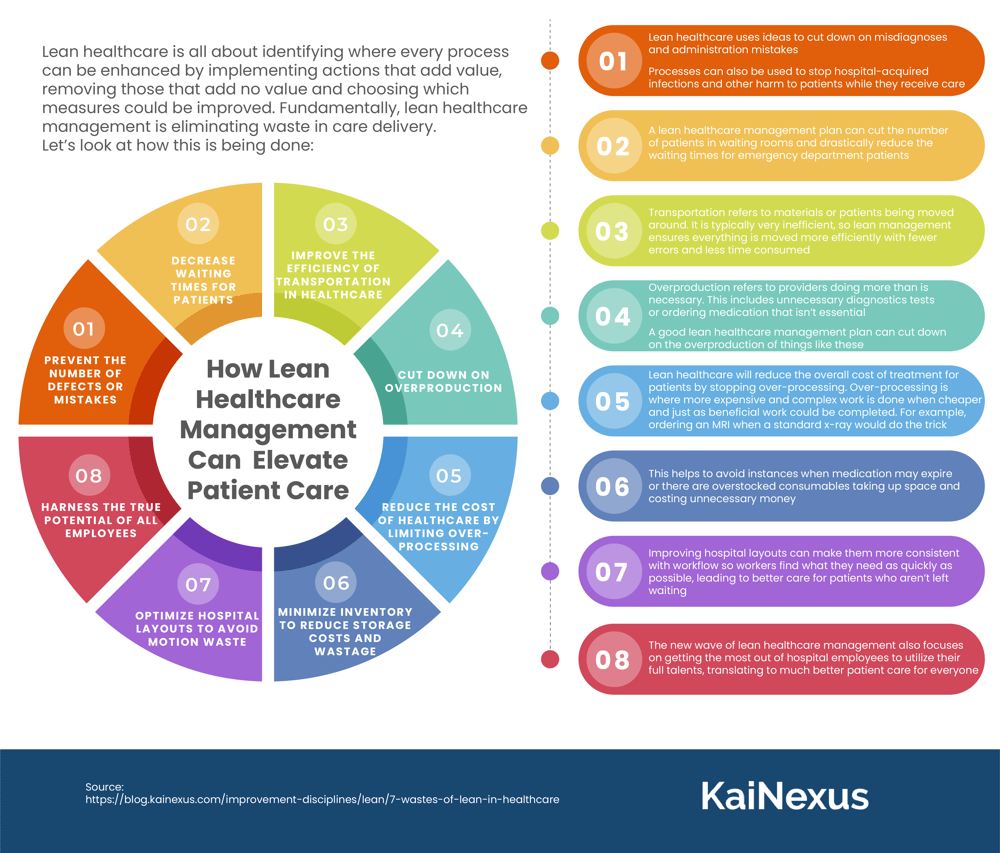

Lean leaders often talk about the “eight wastes.” In healthcare, these aren’t abstract categories—they show up every day in ways that frustrate patients and caregivers alike.

1. Defects/Mistakes

The waste of defects includes the time spent creating a defect, reworking these defects, and inspecting these defects.

- Misdiagnosis

- Administration of incorrect medications

- Hospital-acquired infections and other harm

- Incorrect ICD codes entered

2. Waiting

Waiting in healthcare is a problem for both patients and providers.

- Patients in waiting rooms (or exam rooms)

- Emergency department patients and physicians waiting for test results

- ED patients waiting to be admitted to the hospital

3. Transportation

The waste of transportation occurs when materials (or patients) are moved around inefficiently. In healthcare, it occurs when:

- Medication is transferred from the pharmacy to where it is needed

- Supplies are moved from storage to the floor

- Patients are forced to walk from building to building for different aspects of their care

- Some of this transportation is considered "necessary" waste to be minimized, even if it can't be eliminated.

4. Overproduction

Overproduction is challenging to spot in healthcare, but it occurs when providers do more than is needed by the customer at this moment. It includes:

- Unnecessary diagnostic tests

- Ordering medications that the patient doesn't need

- Uneaten meals

5. Over-processing

Over-processing means doing more work, making it more complex or more expensive than is necessary. It takes the form of:

- Ordering complex diagnostic imagery (MRI) when a simpler method would suffice (X-ray or physical therapy)

- Surgical intervention instead of an equally effective medical alternative

- Treatment by specialists that primary providers could do

6. Inventory

Healthcare organizations seek to minimize inventory to reduce costs related to storage, movement, spoilage, and wastage.

- Medication that may expire

- Overstocked consumables

- Excess bedside equipment

7. Motion

Motion refers to the unnecessary movement of providers and staff within a facility or campus. This happens when:

- Office or hospital layout is not consistent with workflow

- Supplies are not stored where patient care occurs

- Equipment is not conveniently located

8. Human Potential

Some early sources in the Lean literature refer to the 7 wastes of Lean. In recent years, though, most publications have started referring to the eighth type of waste—failing to utilize people's talent or human potential. Examples include:

- Not listening to employees

- Pressuring people to hide and cover up problems

- People habitually working below their level of licensure

Healthcare organizations are using lean to effectively harness the collective intellectual capital of all their team members to maximize value for patients and to slow down the unsustainable cost trajectory of healthcare.

The Role of Leadership: Create Safety First

By 2026, one lesson is clearer than ever: Lean does not work without psychological safety.

If people are afraid to speak up, improvement boards (or software systems) stay empty.

If mistakes are punished, problems stay hidden.

If leaders react emotionally to bad news, learning shuts down.

Effective Lean leaders:

-

Respond calmly to problems instead of reacting

-

Ask better questions instead of issuing quick fixes

-

Model curiosity, humility, and learning

Psychological safety isn’t a “soft” concept—it’s a precondition for continuous improvement.

Lean as a Management System, Not a Toolbox

Lean healthcare is not about copying another hospital’s tools or boards. It’s about developing a management system where:

-

Everyone can identify problems

-

Everyone can suggest improvements

-

Leaders coach instead of command

-

Learning is continuous and visible

Technology—including improvement software—can help make this work scalable and sustainable. But software never replaces leadership behaviors. It only supports them.

Final Thought

Lean healthcare isn’t about working faster. It’s about working smarter, safer, and more humanely—for patients and for those who care for them.

When healthcare organizations truly respect people, design better systems, and create the conditions for learning, patient care rises naturally as a result.

That’s not theory. It’s what I’ve seen, repeatedly, in organizations that commit to Lean as a way of thinking—not just a way of doing.

Add a Comment