If you’re using the Six Sigma methodology to create change and sustain continuous improvement in your organization, you’re likely using, or will use, DMAIC (pronounced "de-may-ick"). DMAIC is an acronym that outlines a framework for identifying and challenging sources of waste, poor quality, and inefficient processes and then looking for opportunities for improvement.

What is DMAIC?

- Define: Outline the goals of the project and the customer deliverables so that it’s known when success has been reached.

- Measure: Assess the current performance of the process to use as a quantified baseline for measurement later.

- Analyze: Uncover the defects to find the root cause of the problem(s) so that you can target improvement work.

- Improve: Identify, implement, and test a solution to resolving the problem(s).

- Control: Determine if the improvement can be maintained, or if it can be used to improve the performance of other processes.

Listen to this Post or Subscribe to the Podcast:

Common DMAIC Mistakes

DMAIC is best used when an existing product or process fails to meet performance expectations or otherwise leaves customers unsatisfied. You can read more about what DMAIC is and about steps involved on our blog, but for those of you who are finding DMAIC challenging you may want to check your organization isn’t making these five big DMAIC mistakes.

- Not collecting enough data.

It is easy for those leading improvement work to get caught up in financial and time cost savings, but this only represents a small amount of the improvement potential that can be captured through the DMAIC method.

It is easy for those leading improvement work to get caught up in financial and time cost savings, but this only represents a small amount of the improvement potential that can be captured through the DMAIC method.

Other benefits such as increased safety and quality, greater employee job satisfaction, customer loyalty, and so much more should be included in the process if possible. Even when these benefits don’t result in monetary rewards directly, they can improve the culture and satisfaction surrounding the organization, which in turn can lead to other improvements that boost the bottom line.

With these other types of improvements, it’s still important to measure them before implementing any changes so that you can verify improvement occurs after plans are implemented. - Sticking to the manual.

If all the opportunities for improvement that are identified and measured are based on what has been documented as the policy or standard, rather than on what is happening in the workplace, those improvements are likely not going to fix the problem.

During the define and measure steps you should be noticing if changes to the documented procedures are being taken, or if there are training deficits contributing to deviations in standard work, which are either helping or hindering results. If you aim to improve what isn’t actually occurring, little improvement can be made. - Blaming the people.

The truth is, employees rarely, if ever, intentionally do a poor job at work. Most employees want to feel valued and productive. However, if even the best and most competent employees are trained inadequately or are working under the limitations of a poorly structured system, failure will be the result. As such, DMAIC should be used to find problems in the processes, not as a way to lay blame on the employees performing those processes.

Further, focusing on the process and how to improve it for the benefit of your employees creates a culture where those employees are comfortable in identifying mistakes and opportunities for improvement. This in turn creates an environment of continuous improvement and aversion to error wherein leaders are there to support their employees so they can have better processes with which to work. Blame processes, not people. - Have leadership figure it out.

For whatever reason, when evaluating process organizations seem to task leadership with both identifying the problem and creating solutions. This of course runs contrary to continuous improvement thinking, which understands the employees doing the work are uniquely qualified to identify opportunities to improve it.

In the practice of DMAIC, cross-functional teams made up of employees from all levels of the organization are better able to identify problems and find opportunities for improvement and analysis. In this way, cross-functional collaboration is the best way to develop an out-of-the-box solution. - Don’t use continuous improvement software.

We don’t like to hit our readers over the head with how much continuous improvement software can help improvement processes, but the role of continuous improvement software in helping organizations use the DMAIC framework is so clear we can’t help but label it as a mistake not to utilize it.

We don’t like to hit our readers over the head with how much continuous improvement software can help improvement processes, but the role of continuous improvement software in helping organizations use the DMAIC framework is so clear we can’t help but label it as a mistake not to utilize it.

Continuous improvement software ensures that ideas are not lost by enabling employees to capture opportunities for improvement at any time, anywhere. Accessing continuous improvement software on a mobile device makes it easy for employees to enter ideas as they occur to them.

Detailed reports showing individual engagement generated by continuous improvement software makes it easy to see who is utilizing DMAIC, which encourages participation and promotes a culture of continuous improvement.

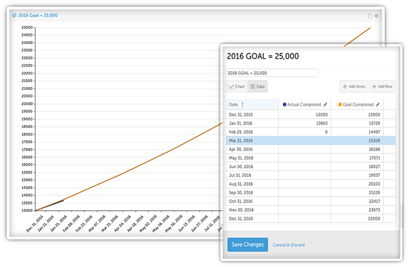

Perhaps continuous improvement software is most helpful in making the measurement of the impact of every improvement through DMAIC (as well as all other continuous improvement initiatives) easy. Continuous improvement software enables organizations to monitor and report back on the impact of the work and the ROI of each improvement.

Finally, continuous improvement software improves communication between frontline employees and leadership, increasing accountability within the improvement process and ensuring follow-up.

So, be careful not to make those five mistakes. By mastering engagement through visibility, ease of access, and accountability success with your DMAIC process is possible.

Do you see others making those mistakes? Have you made any of those yourself or in your organization? Leave a comment if you're willing to share your story or tips.

Add a Comment