"Good Change" Begins with a New Paradigm

"Good Change" Begins with a New Paradigm

Working with organizations of all sizes and in all industries, we've learned that transforming a business to adopt a culture of continuous improvement takes more than a few new policies and a series of meetings. Instead, what's required is a new way of thinking and approaching problems that permeates the way every employee operates every day. Successful organizations worldwide have adopted an approach known as the Kaizen methodology, which was introduced in Masaaki Imai's 1986 book, Kaizen, The Key to Japan's Competitive Success.

What is Kaizen?

Masaaki Imai described Kaizen as, "Kaizen is everyday improvement, everybody improvement, everywhere improvement." The word Kaizen comes from the Japanese words for "Good" (zen) and "Change" (kai). In the workplace, Kaizen refers to activities that continually improve all functions and involve every employee, from the executive team to project managers and frontline workers. Japanese automotive manufacturing businesses embraced the Kaizen method after World War II, leading to improved quality, shorter production times, optimal efficiency, and increased profitability. The Kaizen methodology has since been adopted by organizations in every sector worldwide.

The Principles of the Kaizen Methodology

Kaizen is not a prescription for business process improvement or quality control. Instead, it is a philosophy that informs every decision and informs the culture. The Kaizen philosophy is the basis of many structured improvement methods, including Six Sigma, Lean, Total Quality Management, and the Toyota Production System. The Kaizen Methodology rests on several core beliefs:

Question best practices: There is value in learning from the past, but it is easy to become complacent. Kaizen thinkers break free from the "that's the way we've always done it" mindset and look for improvement opportunities. The status quo is consistently questioned with respect and curiosity.

Embrace problems as opportunities: The first step to positive change is identifying an operation that could produce better results. When waste or defects are uncovered, Kaizen teams jump on the chance to use their problem-solving skills.

Grow through challenges: If you are trying to build your muscles, you might gradually increase the amount of resistance by using heavier and heavier weights. More resistance makes you stronger. The same is true when it comes to continuous improvement. Small wins prepare your team to tackle more complex challenges.

Eliminate excuses: One can always find a reason not to change. The new process may not work. Maybe someone's feelings will be hurt. The results may be insignificant. Embracing Kaizen means putting these excuses aside and trying anyway. Fear of failure is a barrier to improvement.

Don't expect money to solve all problems: While some improvements might require a budget, many more do not. The basis of Kaizen isn't money; it is innovation, creativity, problem-solving, and cooperation.

Leverage the wisdom of many: One person might be an expert in a specific subject, but that doesn't mean they can understand the problem from every point of view. The ideas of process operators and internal and external customers should be considered when implementing improvements.

Make data-based decisions: The only way to know if a change has resulted in measurable improvement is to use baseline performance metrics for comparison. Using quantifiable data will help eliminate assumptions, overcome resistance to change, and make criticism of the status quo less personal.

Learn by doing: The Japanese term "Genchi Gembutsu" means learning by doing things. For example, you can't learn to drive a car by reading books about it or watching others do it; you have to get behind the wheel and practice. The same is true for learning how to apply problem-solving techniques. You will likely make mistakes, but you can manage your experiments by paying close attention to the data.

Look for incremental solutions: Kaizen happens by repeating small, gradual changes rather than disruptive wholesale change. With incremental improvement, processes evolve and move ever closer to perfection.

The Benefits of Kaizen Culture

People often associate Kaizen methods with Lean manufacturing and its goal of waste reduction. Of course, that is an essential benefit of the Kaizen methodology, but it is far from the only one. Others include:

Increased employee satisfaction: Employees get more fulfillment from their work because they directly impact how work gets done.

Improved employee engagement: Employees are more emotionally invested because they have more ownership over the processes they oversee.

Maximized profitability: The organization is more competitive due to improved efficiency leading to lower costs, higher quality, and more innovative products.

Improved consumer satisfaction: Higher quality products with fewer faults leads to happier customers.

How to Spread the Kaizen Mindset

Engaged leadership is the factor most relevant to the organization's ability to spread the Kaizen method. Organizations with leaders who commit to providing the education and resources necessary for continuous improvement get the most out of the approach and see sustained results. Here are some things leaders can do to help spread Kaizen:

- Lead by example. Visibly participate in improvement work with great enthusiasm

- Remind people about the importance of the Kaizen methodology as often as possible

- Frequently ask for ideas for improvement and react quickly to those ideas

- Empower employees to act on opportunities for improvement without fear

- Recognize ideas that produce a positive impact beyond the balance sheet

- Focus on the importance of small, incremental progress. Remember that every improvement doesn't need a project or an event.

- Measure and celebrate the impact of Kaizen

How Technology Supports the Kaizen Method

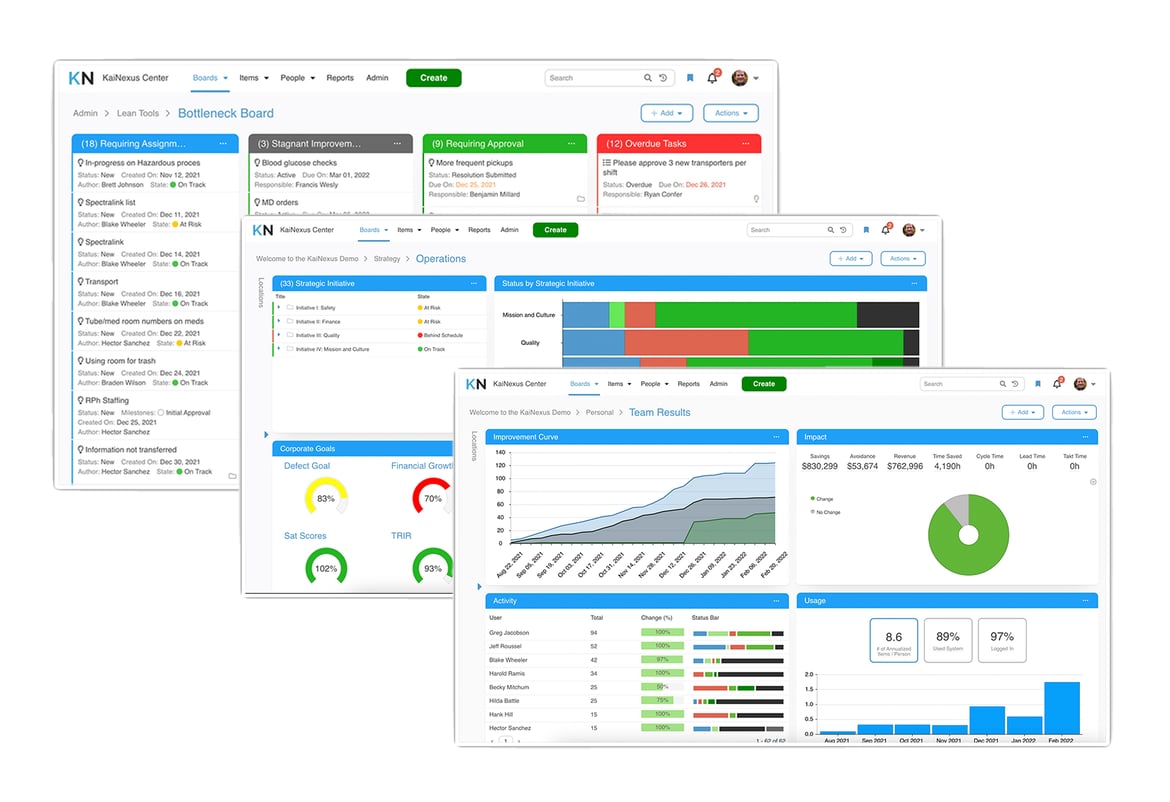

You don't need improvement software to implement the Kaizen methodology, but it helps. Investing in a software platform to collect ideas for improvement, manage their implementation, report results, and broadcast success puts an organization in the best position to get value out of Kaizen. Kaizen and improvement software is the perfect marriage of philosophy and structure. Capabilities to look for include:

Opportunity capture: The platform should be one place for all employees to submit ideas for improvement from anywhere on any device.

Active management: Once an opportunity for improvement is submitted, the solution should route to the supervisor, who can assess and implement it. In addition, there should be alerts and notifications as the ideas selected for experimentation proceed.

Support for Kaizen tools: Organizations that practice Kaizen often use structured improvement tools and visualization techniques. These include daily huddle boards, control charts, X-matrics, and value stream mapping. Kaizen software digitizes these practices, making them widely available and capturing a repository of tribal knowledge.

Reporting: Calculating the value of improvement work is essential in spreading and sustaining Kaizen ideas. Improvement software makes this easy by calculating the impact of each improvement and capturing the non-financial results as well.

Suggested Reading

Here are a few recommended titles in addition to Kaizen, The Key to Japan’s Competitive Success.

- Toyota Kata (2009) by Mike Rother: This book covers how Toyota manages continuous improvement and human respect by making Kaizen an integral part of the culture.

- Gemba Kaizen: A Commonsense Approach to a Continuous Improvement Strategy, Second Edition (2012) by Masaaki Imai: A Commonsense Approach to a Continuous Improvement Strategy, Second Edition (2012) by Masaaki Imai — A second outstanding work by Imai reveals how to implement cost-effective, incremental improvements in your most essential business processes.

- Healthcare Kaizen: Engaging Frontline Staff in Sustainable Continuous Improvement (2012) by Mark Graban and Joseph E. Swartz: This is an excellent resource for those working in healthcare environments.

- How To Do Kaizen (2010) by Bunji Tozawa and Norman Bodek: Although it was written in 2012, this is a timely book on a topic of great importance to managers in uncertain economic times. It describes how, even during a recession, organizations can improve performance levels and come out stronger.

- Creating a Kaizen Culture (2014) by John Miller, Mike Wroblewski, and Jaime Villafuerte: The methods and examples in this book will greatly increase your chances of building a Kaizen culture that leads to true transformation and stands the test of time.

We hope this post has you thinking more about how you can apply the Kaizen methodology to boost productivity, reduce waste, and delight customers and employees. We've seen it work in countless organizations and are sure it could positively impact yours.

![[WEBINAR] Bottom-Up Improvement Software Demo](https://no-cache.hubspot.com/cta/default/326641/8545f357-84e1-47b2-81e0-f4fa0d3cd893.png)

Add a Comment