Many of the continuous improvement tools and techniques that we write about in this blog originated in the manufacturing industry. This makes a lot of sense because mass manufacturing is, by definition, the production of large quantities of standardized products, frequently utilizing assembly line technology. The whole goal is to create large numbers of similar products efficiently. Statistical process control is necessary in order to achieve acceptable quality results at a predictable pace.

Many of the continuous improvement tools and techniques that we write about in this blog originated in the manufacturing industry. This makes a lot of sense because mass manufacturing is, by definition, the production of large quantities of standardized products, frequently utilizing assembly line technology. The whole goal is to create large numbers of similar products efficiently. Statistical process control is necessary in order to achieve acceptable quality results at a predictable pace.

However, the application of statistical methods of process control provides a better understanding of the behavior of any operation. This is an essential piece of management information that is required for making smart decisions about process improvements regardless of the type of process. In addition, the use of statistical methods also provides valuable insight to the employees who are working the process.

Fortunately, one does not need a deep understanding of statistical theory or mathematics in order to apply statistical measurements to improve quality and productivity. The approach can be useful to almost any organization, regardless of the industry.

What are Control Charts?

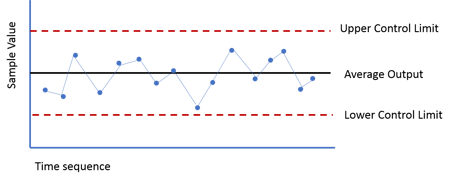

Control charts, sometimes called Process Control Charts or Statistical Control Charts, are simply graphs that plot data related to a process in a time-ordered sequence. They usually include a center line that represents the mean (usually the average, or sometimes the median), an upper control limit, and a lower control limit. The calculated control limits represent the expected process variation from a period of baseline data.

We can apply this methodology to essentially any process output that can be measured. It might include defects, production cycle time, customer complaints, inventory on hand, cost per unit, average sale price, or other important performance indicators, or metrics.

Control limits are usually set at what is essentially the three process standard deviations above and below the average (athough we don't use a calculated standard deviation). This is because if a single data point from measurement falls within plus or minus three standard deviations of its average, it is usually considered expected behavior for the process.

Here’s a simple example in this chart:

Process Variation

When a process is running as expected, some common cause variation is normal. Common cause variation results from the ordinary operation of a process and is anticipated due to the design of the process, process tasks, input materials, and other typical factors.

When a single data point falls outside of the control limits, that is an indication that something unusual has occurred during the process. This is known as special cause variation and is an indication that something has gone awry and is worth investigating in the context of "what happened that time period?" With common cause variation, we need to reduce it through a more systemic analysis of our system and process over time, instead of asking the reactive "what happened?" question.

Non-Manufacturing Use Cases

As we mentioned, control charts can provide useful information when applied to any process with measurable outputs. In all cases, the first goal is to eliminate special cause variations and to make improvements that will produce better average results, thus shifting the mean in a positive direction. The next goal is to reduce common cause variation and to take other actions that can improve the average result.

Regardless of the industry, the steps to implementing improvements based on statistical control are the same:

- Define what needs to be controlled and measured

- Identify the measurement system that will supply the data

- Create the control charts

- Collect and chart the data

- Implement and preventative measures based on control chart information

Here are a few examples.

Healthcare:

- Patient wait times

- Billing errors

- Hospital readmission

- Hospital-acquired infections

- Repeated diagnostic tests

- Missed appointments

Software Development:

- Code defects per release

- Customer support calls

- Support ticket time to resolution

- Website page load times

- Feature enhancement requests implemented

Finance:

- Data entry errors

- Days to collection

- Past due invoices

- Invoice processing time

- Operating expenses

Human Resources:

- Accrued paid time off liability

- Unplanned absences

- Time between position posting and hire

- Cost per to hire

- Average employee tenure

These are just a few examples to get you thinking about how control charts might be useful in your organization. Of course, we would be remiss if we didn’t mention that control charts can also be useful for the management of improvement itself. You might chart the number of employee identified opportunities for improvement or the time it takes management to respond to those suggestions. Useful data can be found by charting how long it takes to implement each improvement and the quantifiable impact of each completed project.

Advantages of Process Control Charts

Implementing control charts as a method for evaluating process performance helps you:

- Establish a common language for discussing process performance and behavior

- Make smart decisions about which processes are fine as they are, and which require immediate attention

- Reduce the need for post-production inspection

- Figure out process capability based on past performance and trends

- Evaluate the impact of process changes

- Visualize the performance of the process over time

- Establish baseline results for future improvements

- Communicate the performance

- Avoid overreacting to every up and down in the data (the common cause variation)

We are delighted to see more organizations think creatively about how statistical control can be used to measure and improve processes of all sorts. We’d love to revisit this topic with more examples and greater detail about how process control charts are used outside of manufacturing. If you have an example you’d like to share, please drop a note in the comments.

Add a Comment