There’s a reason that it’s almost impossible to talk about continuous improvement without talking about Toyota Motor Corp. They not only embraced the philosophy of Kaizen, but they developed a host of processes and tools to support it.

There’s a reason that it’s almost impossible to talk about continuous improvement without talking about Toyota Motor Corp. They not only embraced the philosophy of Kaizen, but they developed a host of processes and tools to support it.

One of their most valuable developments is called A3.

The A3 process is designed to solve problems and offer a method for realizing opportunities for improvement.

The Benefits of A3

The A3 process, which aligns to Deming's 'Plan-Do-Study-Act' approach, offers several benefits:

- Provides a structured thinking process for solving problems

- Presents information objectively

- Requires focus on only critical information

- Offers a consistent approach to problem solving

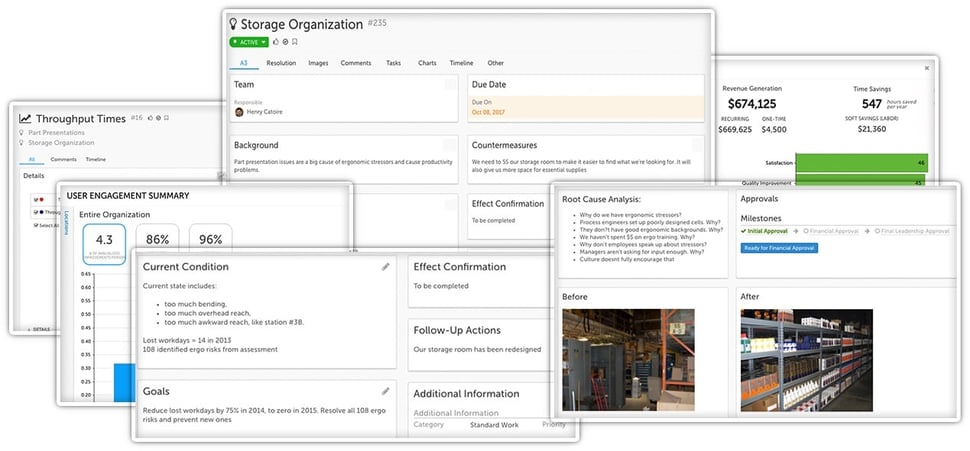

The A3 Report

A3 reports get their name from the A3-sized sheet of paper (approximately 11x17) on which they are designed to fit. An A3 report is one page that documents the results from the PDSA cycle.

Although the steps can vary depending on the organization and the particular need, the following workflow is typical:

- Identify the problem (Plan)

- Form the team (Plan)

- Define and document the current state (Plan)

- State the goal (Plan)

- Conduct a root cause analysis (Plan)

- Deploy countermeasures (Do)

- Measure and confirm results (Study)

- Set follow-up actions (Act)

- Document changes and report results (Act)

As you can tell, a lot of effort is put into the planning phases. This helps eliminate opportunities for error and ensure positive results. Of course, like all other business process improvement methods, everything begins when a problem (or an opportunity for improvement) is identified. Therefore, it is essential that organizations create a culture where problem identification is respected and encouraged. It is also necessary to provide tools that make it easy to gather opportunities for improvement so that the A3 cycle can begin.

The A3 process is an effective format for collaborative, deep problem-solving. Its focus on the root causes of issues helps avoid the fire fighting and Band-Aiding of problems that is so common without this type of structure. It can be applied to almost any type of problem and can result in very rapid, lasting improvement.

![[Watch Now] How to Use A3 Thinking in Everyday Life](https://no-cache.hubspot.com/cta/default/326641/312227ef-895d-48da-b9ee-ee61a5b19930.png)

Add a Comment