If you are new to the idea of a structured approach to continuous improvement, this post is perfect for you. We will lay out the basics of some of the most common tools used to grease the skids for improvement efforts. We'll also include links to more complete content on each one, so you can dig in more to the ones that catch your attention. There are no rules about what tools you must use, and not every tool is right for the job, but this overview should help you get started finding out what will work best for your organization.

If you are new to the idea of a structured approach to continuous improvement, this post is perfect for you. We will lay out the basics of some of the most common tools used to grease the skids for improvement efforts. We'll also include links to more complete content on each one, so you can dig in more to the ones that catch your attention. There are no rules about what tools you must use, and not every tool is right for the job, but this overview should help you get started finding out what will work best for your organization.

A3 Problem-Solving

A3 is a structured problem-solving approach that was first developed by Toyota. It's named after the final report that is one page (A3 is a standard European paper size) that documents the results from the PDCA cycle. Requiring the information to be condensed to one page helps people focus on what's important.

5S (Sort, Set, Shine, Standardize, Sustain)

5S is a workplace organization technique based on the Japanese words: seiri (sort), seiton (set), seiso (shine), seiketsu (standardize), and shitsuke (sustain). The method was started in the manufacturing industry as a way of maintaining efficiency and safety. Today, workplace organization is essential in several sectors, including healthcare, education, finance, and construction.

Catchball

Catchball is a method borrowed from the Hoshin Kanri approach in Lean manufacturing. It is the structured process of moving ideas from person to person, up and down the organization. The goal is to define the purpose, objectives, and challenges of each improvement project. Every stakeholder gives input and feedback until a plan for the changes is developed and implemented.

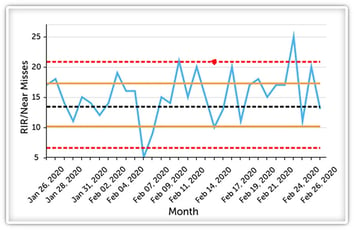

Control Charts

Control charts are a favorite in the manufacturing sector, but they can be useful for all sorts of data. Data is plotted over time on a chart that has both upper and lower control limits. Visualizing the information this way makes it easy for supervisors and process operators to differentiate between common cause (expected) variation, and special cause (unexpected) variation, which may indicate a reason for concern.

DMAIC (Define, Measure, Analyze, Improve, Control)

DMAIC is a structured improvement cycle that uses five steps to structure improvement projects. DMAIC helps ensure that each step of the process is based on data, that results are measurable, and that improvement can be sustained.

Gemba Walks

In Japanese, Gemba means "the real place." During a Gemba walk, managers or supervisors go to the place where work is done to observe and identify improvement opportunities. The workplace may be a factory floor, an office, a classroom, or even a Zoom meeting with people working from home. The leader asks questions, observes processes, shows respect for employees, and documents what they find. After a period of consideration, opportunities for improvement are documented and implemented.

Hoshin Kanri (Policy Deployment)

Hoshin Kanri is a strategy deployment tool that ensures everyone in the organization is driving toward the same goals, sometimes called "true north." It helps leaders balance the imperative to achieve long term goals with the need to address daily improvement opportunities.

Kanban

Kanban is a visualization tool for displaying the state of work in progress to maximize the flow of goods and work. When the state of work is visualized, leaders can quickly see interruptions in flow and roadblocks that cause waste. Kanban can be implemented with physical cards like those used by Toyota to manage inventory, or digital Kanban boards can be used for visualizing other types of work.

PDSA (Plan, Do, Study, Act)

PDSA is another improvement cycle, also known as the Deming Cycle. It is a simple, yet powerful tool for ensuring that fixes to problems aren't implemented without the necessary analysis and documentation. Once the cycle is finished, it starts again with a new improvement plan.

Standard Work

Standard work is the documented current best practice for any process or task. It represents the basis for the PDSA or DMAIC improvement cycle. The Standard work must be complete, easily accessible in the place where work is done, and always up to date.

The 5 Whys

The 5 Whys is a technique for discovering the root cause of a problem. It starts with a statement of the issue, followed by the question, "Why?" The question is repeated until the root cause of the problem is uncovered. This usually takes about five tries. Once the actual reason is revealed, effective corrective action is applied.

Value Stream Mapping (VSM)

Value Stream Mapping is a technique for documenting and analyzing each step of the flow of value to the customer. Creating a visual representation of the value stream helps identify and eliminate waste within the stream. It can be applied to a stand-alone process or used more systemically across the entire value chain.

You have many choices when it comes to process improvement tools. You might not use all of them, but it is smart to learn more about each one so that you can have the tool you need at your disposal.

Add a Comment