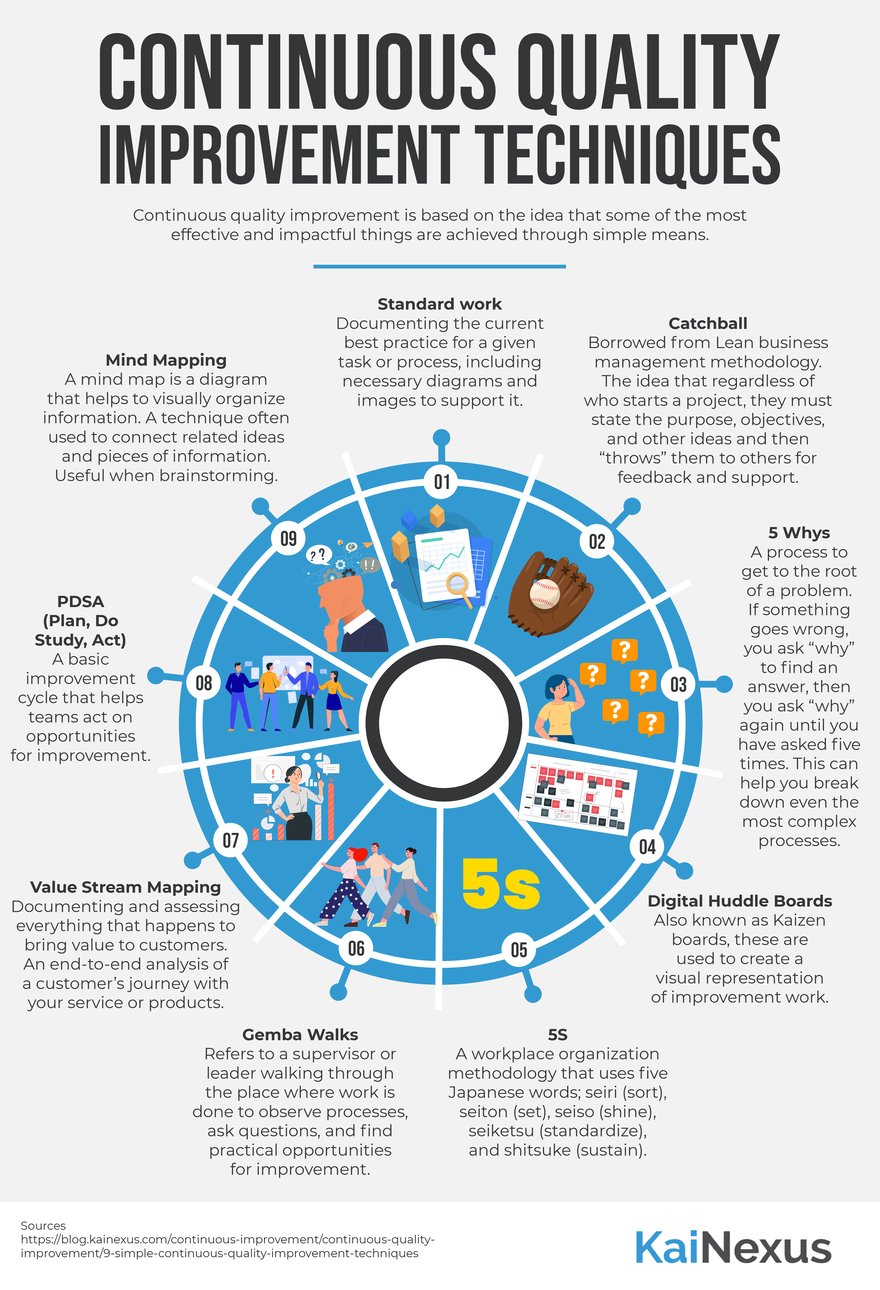

I often find myself falling into the common trap of believing that if something is worthwhile, it is necessarily difficult. I think we all expect that valuable things are hard. The truth is, however, that sometimes the most effective and impactful things we can do are really quite simple.

I often find myself falling into the common trap of believing that if something is worthwhile, it is necessarily difficult. I think we all expect that valuable things are hard. The truth is, however, that sometimes the most effective and impactful things we can do are really quite simple.

When it comes to continuous quality improvement, this is absolutely the case.

Here are 9 examples of quality improvement tools, techniques, and technology that are uncomplicated yet extremely valuable.

1. Standard Work: Creating Your Quality Baseline

What is Standard Work?

Standard work is the documented best practice for executing any task or process within an organization. It serves as the foundation for all continuous improvement initiatives by establishing a measurable baseline.

Key Components of Standard Work:

-

Detailed step-by-step procedures for tasks

-

Supporting visual aids including diagrams and images

-

Accessibility for all team members performing the work

-

Input and design from frontline workers

Why Standard Work Matters:

Without documented standard work, improvement becomes impossible. You cannot optimize what you cannot measure. Standard work provides the consistency needed to identify variations, measure performance, and implement systematic enhancements to efficiency and effectiveness.

Business Impact: Organizations with robust standard work documentation experience reduced training time, improved quality consistency, and faster onboarding of new employees.

2. Catchball: Collaborative Communication

What is Catchball?

Catchball is a Lean management methodology that facilitates bidirectional communication throughout project lifecycles. The concept derives from the physical act of throwing and catching a ball, symbolizing the exchange of ideas and responsibilities.

How Catchball Works:

The project initiator (typically a manager or team lead) defines the purpose, objectives, ideas, and concerns, then "throws" these elements to team members for feedback, refinement, and action. This creates clear ownership at each stage, ensuring everyone knows who currently holds responsibility.

Benefits of Catchball:

-

Enhanced cross-functional communication

-

Clear accountability and ownership tracking

-

Incorporation of diverse perspectives

-

Reduced project delays and misalignment

Implementation Example: In product development, a product manager might initiate catchball by sharing requirements with engineering, who refines technical specifications before passing to design, creating a collaborative flow that prevents siloed decision-making.

3. The 5 Whys: Root Cause Analysis Made Simple

What is the 5 Whys Technique?

The 5 Whys is a problem-solving method that identifies root causes by iteratively asking "why" approximately five times. This simple yet powerful tool moves beyond surface-level symptoms to uncover underlying systemic issues.

How to Conduct the 5 Whys:

-

Identify the problem clearly

-

Ask why the problem occurred

-

For each answer, ask why again

-

Continue for approximately five iterations

-

Implement corrective actions addressing the root cause

Real-World Application:

Problem: Production line stopped.

-

Why? Machine overheated.

-

Why? Insufficient lubrication.

-

Why? Maintenance schedule wasn't followed.

-

Why? No automated reminder system.

-

Why? Budget wasn't allocated for maintenance software.

Root Cause: Inadequate investment in preventive maintenance systems.

Quality Impact: By addressing root causes rather than symptoms, the 5 Whys prevents problem recurrence, directly improving quality, reliability, and reducing operational costs.

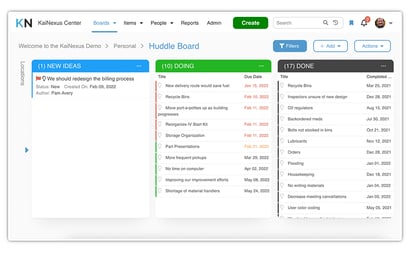

4. Digital Huddle Boards: Visual Management for Continuous Improvement

What are Digital Huddle Boards?

Digital huddle boards (also called Kaizen boards or visual management boards) provide real-time visual representation of improvement initiatives across the organization. These electronic dashboards make project status, bottlenecks, and achievements immediately visible to all stakeholders.

Key Features of Effective Huddle Boards:

- Real-time project status updates

- Visual indicators for stalled initiatives

- Accessibility from any location

- Metrics tracking and trend analysis

- Team accountability and ownership display

Business Benefits: Organizations using digital huddle boards report faster project completion, minimized delays, optimized resource utilization, and improved team engagement in improvement activities.

5. 5S Methodology: Workplace Organization for Efficiency

What is 5S?

5S is a systematic workplace organization method originating from five Japanese terms that create structured, efficient, and safe work environments.

The Five Pillars of 5S:

-

Seiri (Sort): Remove unnecessary items from the workplace

-

Seiton (Set in Order): Organize remaining items logically

-

Seiso (Shine): Clean and inspect the workspace regularly

-

Seiketsu (Standardize): Create standards for the first three steps

-

Shitsuke (Sustain): Maintain discipline and continuously improve

Why 5S Matters for Quality:

An organized workplace is fundamental to operational efficiency and safety. 5S particularly addresses waste reduction in motion and transportation—two of the eight wastes identified in Lean methodology.

Measurable Outcomes:

-

Reduced search time for tools and materials

-

Improved workplace safety metrics

-

Enhanced productivity through ergonomic workspace design

-

Decreased inventory carrying costs

-

Better quality control through visual management

6. Gemba Walks: Leadership on the Front Lines

What is a Gemba Walk?

Gemba (meaning "the real place" in Japanese) walks involve leaders visiting the actual location where work occurs to observe processes, engage with employees, and identify improvement opportunities.

How to Conduct Effective Gemba Walks:

The focus is observation and learning, not evaluation or criticism. Leaders should:

-

Go to where the work happens

-

Observe standard work execution in real conditions

-

Ask open-ended questions to understand challenges

-

Listen actively to frontline worker insights

-

Look for improvement opportunities collaboratively

Integration with Other Techniques: After a Gemba walk, leaders often use Catchball to initiate improvement projects or the 5 Whys to investigate identified issues.

7. Value Stream Mapping: End-to-End Process Optimization

What is Value Stream Mapping?

Value Stream Mapping (VSM) is a visual tool that documents and analyzes every step in delivering value to customers, from initial requirements through final delivery. This Lean technique identifies value-added activities while exposing waste and inefficiency.

Components of Value Stream Maps:

-

Process steps and cycle times

-

Information flows

-

Material movements

-

Wait times and delays

-

Value-added vs. non-value-added activities

-

Lead time analysis

Creating a Value Stream Map:

-

Select the product or service to map

-

Document the current state with all process steps

-

Identify value-added vs. non-value-added activities

-

Calculate total lead time and process time

-

Design the future state eliminating waste

-

Create an implementation plan for improvements

Business Impact: Value stream mapping increases customer satisfaction through reduced lead times, enhances overall efficiency via targeted improvements, and systematically eliminates the eight types of waste (defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, extra-processing).

8. PDSA: Plan-Do-Study-Act for Continuous Learning

What is PDSA?

PDSA (Plan-Do-Study-Act), also known as the Deming Cycle, is a fundamental improvement framework that guides teams through structured experimentation and learning.

The Four Phases of PDSA:

Plan:

-

Understand the current state thoroughly

-

Define the desired future state

-

Identify specific changes to test

-

Establish success metrics

Do:

-

Implement changes on a small scale

-

Document everything during implementation

-

Collect data on results

Study:

-

Analyze results against predictions

-

Identify what worked and what didn't

-

Understand unexpected outcomes

-

Determine if changes should be adopted, adapted, or abandoned

Act:

-

Update standard work if changes are successful

-

Implement the new process organization-wide

-

Begin the cycle again for further improvement

Why PDSA Works:

This iterative approach reduces risk by testing changes before full implementation, creates organizational agility, and builds a culture of experimentation and learning.

Organizational Impact: Companies using PDSA cycles demonstrate enhanced productivity through tested improvements, improved quality via data-driven decisions, and greater adaptability to changing market conditions.

9. Mind Mapping: Visual Thinking for Innovation

What is Mind Mapping?

Mind mapping is a visual brainstorming technique that organizes information hierarchically, revealing connections between concepts and making complex relationships clear.

Mind Map Structure:

Like a tree, mind maps begin with a central concept (the trunk) and branch outward to related ideas of decreasing granularity:

-

Core concept (center)

-

Major themes (main branches)

-

Supporting ideas (secondary branches)

-

Details (twigs)

Applications in Continuous Improvement:

-

Process development and redesign

-

Problem-solving sessions

-

Project planning and scope definition

-

Quality control strategy

-

Innovation workshops

-

Knowledge gap identification

-

Team brainstorming facilitation

Why Mind Mapping Works:

The visual format engages both analytical and creative thinking, makes knowledge gaps immediately visible, and helps teams see relationships that linear notes obscure.

Best Practices: Use colors to categorize information, include images for memory retention, keep branches concise, and create mind maps collaboratively for team alignment.

Frequently Ask Questions

What is the difference between continuous improvement and Kaizen?

Continuous improvement is the broader concept of ongoing incremental enhancements to processes, products, or services. Kaizen is a specific Japanese philosophy and methodology that embodies continuous improvement through small, daily changes involving all employees. Essentially, Kaizen is one approach to achieving continuous improvement, though the terms are often used interchangeably in Western business contexts.

Which continuous improvement technique should I start with?

Start with Standard Work. Without documented baseline processes, you cannot effectively measure improvements or identify problems. Once you have standard work established, add the 5 Whys for problem-solving and PDSA for testing improvements. These three techniques form a solid foundation for any continuous improvement program.

Can small businesses benefit from continuous improvement techniques?

Absolutely. Continuous improvement techniques are often more impactful in small businesses where changes can be implemented quickly with less bureaucracy. Start with low-cost, high-impact methods like Standard Work, the 5 Whys, and 5S. Small businesses often see faster ROI because improvements can be tested and scaled more rapidly.

What are the most common mistakes when implementing continuous improvement?

Common pitfalls include: starting without Standard Work documentation, implementing too many techniques at once, lacking leadership commitment, failing to involve frontline workers, not celebrating small wins, giving up too quickly, and treating continuous improvement as a project rather than an ongoing culture. Success requires patience, consistency, and genuine organizational commitment to incremental daily improvement.

Add a Comment