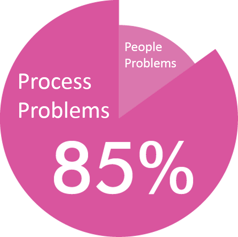

Dr. W. Edwards Deming, a towering intellect whose thinking about improvement affected a quality revolution of gargantuan significance on American manufacturers and consumers, once said, “Eighty-five percent of all performance problems are not people problems, they are process problems.”

Dr. W. Edwards Deming, a towering intellect whose thinking about improvement affected a quality revolution of gargantuan significance on American manufacturers and consumers, once said, “Eighty-five percent of all performance problems are not people problems, they are process problems.”

His statement holds true in every business from manufacturing to health care. What’s more, people problems are generally easy to spot. Process problems, on the other hand, can be very difficult to hone in on, especially by managers and leaders who are removed from the day-to-day tactical work. That’s where the Lean technique called Gemba Walks comes in.

What is a Gemba Walk?

The word Gemba is Japanese for “the real place.” In terms of business, it means the place where work is actually done. It may be a factory floor, an office full of cubicles, or an operating room. A Gemba Walk is the practice of managers, supervisors, and leaders going to the place where their employees add value to observe processes and look for opportunities for future improvement.

What a Gemba Walk is Not

The purpose of a Gemba Walk is to uncover some of the 85% of your organization's problems that are caused by flawed processes. It is not a performance evaluation or the right time to focus on the behavior of employees. Handling people problems during the Gemba Walk will make it an adversarial endeavor and erode the trust that is necessary to truly get to the root cause of process failures. It's important that employees understand that you're there to support them, rather than to judge them.

Tips from the Pros

We’re lucky enough to chat with talented leaders who are dedicated to daily incremental improvement. Here is some of their best advice on Gemba Walks:

- Before you begin your first Gemba Walk, make sure its purpose is clearly communicated and that employees have the opportunity to ask questions.

- Focus on one process at a time and don’t confuse a Gemba Walk with Management by Walking Around.

- Take careful notes, sketch diagrams, and take pictures if applicable.

- Unless there is an urgent safety issue, resist the urge to make changes or even suggest them during the Walk.

- Ask lots of questions – who, what, where, how, and most importantly why.

- Make sure something happens as a result of your Walk by leveraging your continuous improvement software to document your observations, assign ownership of the improvement cycle, and track progress.

- Keep in mind that processes may be executed differently during different shifts, days of the week, or times of the year, so it is important to vary the timing of your Gemba Walks.

Deming also said, “It is a mistake to assume that if everybody does his job, it will be all right.” Your people could be perfect, but if processes are flawed, you won’t get the results you seek. Gemba Walks are a powerful tool in the fight against the 85%.

Download this free eBook to learn way more about Gemba Walks!

The Guide to Successful Gemba Walks

The Guide to Successful Gemba Walks

Download this free guide to learn:

- What Gemba Walks are - and how they're different than Management By Walking Around

- Why they're so important for leaders of continuous improvement

- Tips to promote successful Gemba Walks

- How to ensure that Gemba Walks result in actual improvements

Add a Comment