![]() Lean production, also referred to as Lean manufacturing or Lean business, is a methodology that helps businesses and non-profit organizations reach their short and long-term goals. Although Lean production originated in the manufacturing sector, it is now used by organizations of all industries and sizes. It is widely used in organizations as diverse as construction, education, software development, and healthcare.

Lean production, also referred to as Lean manufacturing or Lean business, is a methodology that helps businesses and non-profit organizations reach their short and long-term goals. Although Lean production originated in the manufacturing sector, it is now used by organizations of all industries and sizes. It is widely used in organizations as diverse as construction, education, software development, and healthcare.

Lean production rests on three simple concepts, all supported by the core belief that respect for people must always drive decisions.

-

Deliver whatever your customer considers valuable

-

Reduce waste, which is everything that the customer does not value

-

Continuously improve

In short, Lean production is a systematic operations methodology used for eliminating waste within any production system. It addresses the waste generated from uneven workloads and reduces them to maximize value and lower costs. The word ”lean” refers to no waste.

What is the background of Lean production?

After the second world war, Toyota was fully committed to improving its products while lowering costs by minimizing materials and activities that don’t add value that their customer would recognize. As a result, they succeeded in enhancing the quality, reducing cycle times, and becoming far more efficient. This led to a significant increase in profitability and a worldwide reputation for customer value.

The approach was first called the Toyota Production System. Then, in the 1980s, an article called “The Triumph of the Lean Production System, by John Krafcik went what we would today call “viral” and introduced the world to Toyota’s waste reduction and continuous improvement approach.

What are the Principles of Lean?

Identify Customer Value

Every organization strives to deliver a product or service for which a customer will be happy to pay, or in the case of non-profits, services that further the mission. In either case, the value must be defined by the customer or beneficiary.

Value comes from solving problems. In Lean production, any task, activity, material, or feature that does not contribute value is considered waste.

Understand the Value Stream

To understand the difference between value and waste, Lean organizations map the entire production process, including the actions, workers, and processes contributing to the final product. This practice helps clarify what is productive and what is unnecessary.

Visualizing the value stream makes it clear which processes can be eliminated or minimized without negatively impacting the customer.

Streamline Flow

Once the value stream is fully understood, Lean production requires implementing a continuous and uninterrupted flow of value to the customer.

Often cross-functional collaboration is necessary to achieve this goal. Several Lean production tools assist with continuous monitoring of flow by visually representing the movement of work-in-progress and making bottlenecks apparent.

Operate with a Pull System

The idea of a pull system is one of the unique aspects of Lean production. Work in progress is only moved from one step to the next when there is demand. This applies to the production of final products, which are only created when the customer orders them and internal work-in-progress.

For example, in a software development organization using Lean production, the wireframes with screen designs are not created by the designer until the coders have the capacity to develop the application. Likewise, application development does not outpace the ability of the quality assurance team to test the software.

Continuously Improve

Lean production is not a goal or an event. Instead, it is a method for achieving excellence through incremental improvement and continuous monitoring or operations. Lean leaders recognize that customer needs change over time, so no system can operate in a vacuum. In addition, problems can crop up in even the best-planned process, so continuous improvement becomes a chief responsibility of every employee in the organization.

What are the advantages of Lean production?

Lean production is widely used because it can be adjusted to meet the needs of various organizations but still retain a structure that generates the desired results.

Lean production delivers several critical benefits:

Customer Focus

Because Lean production is centered around delivering value to the customer with minimum waste, it is easier to make decisions and set priorities.

Better Efficiency and Productivity

When organizations eliminate waste, they can focus materials, time, and attention on the elements of the production process that create value and spend less time on unnecessary tasks, saving both time and money.

Improved Employee Engagement

Lean production gives process operators the dignity they deserve. The workers are in the best position to recognize and implement opportunities for improvement. The approach encourages employee engagement and emotional investment. Engaged employees are more productive and less likely to leave the organization.

Higher Quality Results

Lean organizations do not apply Band-aid type fixes to production problems. Instead, they search for the root cause and apply fixes that address the underlying issue. Thus, defects and rework are rare.

What are the types of waste in Lean production?

Reducing waste is easier if you know where to look for it. Some waste is easy to spot, but it can be insidious and difficult to root out. For that reason, Lean production focuses on eight typical causes of waste.

Defects

Perhaps the most glaring form of waste, defects are any process result that is not acceptable to the customer or the next step in the process. Rework is also a type of defect.

Transportation

The movement of raw materials or products that is unnecessary or of greater distance than needed is the waste of transportation.

Motion

In the same way, the unnecessary movement of people or equipment constitutes the waste of motion.

Excess Inventory

Inventory waste is storing raw materials, supplies, or finished products. In this case, the capital involved in procuring the items and the space to keep them is wasted.

Waiting

The waste of waiting happens when a process is interrupted because the necessary inputs are not ready. Waiting is an indication that flow is blocked.

Over-production

When work-in-progress or products are created before customer demand, over-production is in play. Over-production breaks the pull system.

Over-processing

Features, information, packaging, or other elements of a product or process that the customer does not need represents over-production.

Underutilized Skills

The failure to utilize the skills, ideas, talents, and capacity for the input of every employee is perhaps the most regrettable waste of all.

Which tools are used in Lean production?

The Lean production philosophy has been around for generations, and as you might expect, many tools and techniques have been developed to bring the principles into practical application. Whether your team goes all-in on Lean or only uses a few, they can be helpful as problem-solving and continuous improvement tools.

Standard Work

In Lean production, Standard Work is the documented current best practice that operators use for any process or task. Standard work produces consistent results that are used as the baseline for improvement. Standard work documentation should be developed by the process operators and available where work is done. When improvements to the processes are implemented and tested, the team updates the Standard work documentation.

The PDSA Improvement Cycle

Plan, Do, Study, Adjust, is a structured cycle for solving problems and implementing improvements. It is useful in Lean production for maintaining a consistent and organization-wide improvement methodology.

A3 Reports

A3 reports are a consistent way to capture and share the activities and results of the PDSA cycle. They help teams concisely identify the problem to be addressed, capture the current state, identify potential solutions, and measure the results.

Kanban Boards

Kanban boards are the Lean production approach to visualizing the flow of work-in-progress. They help ensure uninterrupted flow and enforce the pull system.

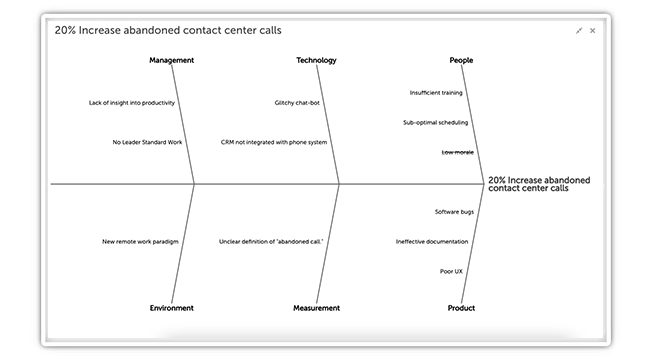

Fishbone Diagrams

While the root causes of some problems are easy to find with a simple approach like the 5 whys, others require more digging. A fishbone diagram breaks down potential causes into common categories that are charted in a way that resembles the skeleton of a fish. By considering each possible cause, teams can ensure that all possibilities are addressed.

Lean Production Software

Today, software solutions are available to support each Lean production tool. By leveraging one platform for improvement efforts, teams become more efficient at problem-solving, and leaders get constant insight into the health of Lean within the entire organization.

Lean production has helped many organizations achieve operational excellence through daily improvement and waste reduction. Contact one of our improvement efforts to learn more about how our customers are experiencing success.

![[Watch Now] How to Leverage Lean for Long-Term Success](https://no-cache.hubspot.com/cta/default/326641/eb5ac7b8-b040-48b7-810e-1589561ffff9.png)

Add a Comment