.png?width=400&name=placeit%20(4).png) We talk to people who are looking for ways to get more efficient with their continuous improvement efforts every day. Many are already using the Lean management method, others are just getting started with Lean, and some are taking a "Lean light" approach by adopting some of Lean's principles without going all in. In any case, leaders want to know what to expect and how the Lean management system can help them improve and achieve their most important goals. Luckily, we are well-positioned to share what our customers have told us happened when they invested in technology to bolster their efforts to improve and reduce waste.

We talk to people who are looking for ways to get more efficient with their continuous improvement efforts every day. Many are already using the Lean management method, others are just getting started with Lean, and some are taking a "Lean light" approach by adopting some of Lean's principles without going all in. In any case, leaders want to know what to expect and how the Lean management system can help them improve and achieve their most important goals. Luckily, we are well-positioned to share what our customers have told us happened when they invested in technology to bolster their efforts to improve and reduce waste.

There is a Unified Version of the Truth

An organization's Lean management system software becomes a record of all improvement work in one unified platform with comprehensive access for leaders and employees. Instead of sorting through piles of email and confusing spreadsheets, everyone knows exactly where to go to report an opportunity for improvement or work on implementing one. Each of the related documents, images, and other assets are stored right alongside the data about each project, simplifying cross-functional collaboration.

People Can Work on Improvement Anytime, from Anywhere

Work on Lean projects shouldn't be limited by time or place. If you choose a cloud-based Lean management system, you remove obstacles that keep people from submitting their ideas or working on active projects. Each employee can access the system from wherever they are on whatever device they like. Team leaders can digitize your huddle boards to be productive in meetings even if they aren't physically standing in front of your boards.

A Common Improvement Language Evolves

In communities as well as organizations, a shared language helps to bring people together. Creating a Lean culture is more natural if everyone can talk about improvement activities and goals using the same vocabulary. Digital Lean management systems help to establish the group of terms that your team will use to discuss improvement and reinforces that language each time someone uses the solution.

People Take Lean More Seriously

Employees know that what leaders invest money and time on is what they think is essential. If executives say that something is a priority, yet they don't spend money on it, people will know that the commitment isn't there. Rolling out Lean is a big deal. If it is going to be as transformative as you hope, it requires commitment, which means investment. Implementing software to support the Lean initiative lets your team know that this isn't just the philosophy of the month.

Improvement Work Happens Faster

One main reason that we don't recommend spreadsheets for Lean management is that they are passive. Spreadsheets only get opened and used when someone thinks to do it. With a Lean management system, managers and team members get alerts and notifications when needed to keep them engaged in improvement activities. When a due date nears, everyone knows about it, so it is easy for managers to know when they need to step up and provide motivation or remove obstacles.

Tribal Knowledge Grows

Your Lean software platform creates a storehouse of all the learnings across the entire organization. Information about every completed and ongoing project and relevant documents are assembled in one place that anyone can access. An improvement that is started today benefits from the collective wisdom of the team. Users know what has worked well and what hasn't turn out to be very useful.

Leaders Gain Essential Insight

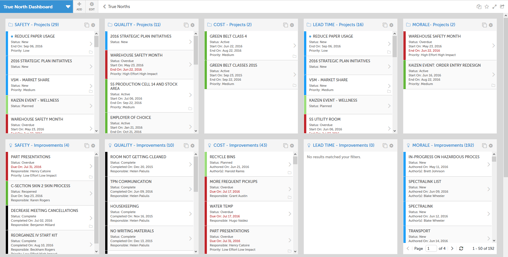

Lean is usually related to an organization's strategic plan for achieving breakthrough goals and minimizing waste. Leaders are much more effective when they have access to information about the health of Lean across the entire organization. Lean software systems are equipped with a dashboard that leaders can use to steer the organization to the desired results. They know which departments, teams, and people are engaged, and they have a handle on all of the improvement actives underway.

Goals Become Aligned

Strategy deployment is an essential element of Lean. It requires that group and personal goals be aligned with the strategy and objectives of the organization. Lean management technology makes it simple to cascade goals down from the boardroom to the front-line employees. Lean related work is tied back to the strategy, simplifying prioritization of tasks and decision making.

You Can Calculate the ROI of Lean

Although we are listing it last, the ability to calculate the impact of Lean is one of the most significant benefits of Lean software. By choosing a solution with advanced impact reporting, you can calculate each improvement in terms of both initial and ongoing results. You will know if your Lean efforts saved money, improved customer satisfaction, impacted quality, or got products to market quicker.

Every other important function in your organization almost certainly has technology to support it. Our clients have found that supporting Lean requires the same degree of commitment. It's the surest way to put your team in the best possible position to succeed.

![[Watch Now] How to Leverage Lean for Long-Term Success](https://no-cache.hubspot.com/cta/default/326641/eb5ac7b8-b040-48b7-810e-1589561ffff9.png)

Add a Comment