![]() Many books and articles about good leadership focus on interpersonal relationship skills like communication, humility, and empathy. Of course, all of these traits are important for good leadership. Still, they don't directly address the most critical responsibility of a leader, which is to create systems and infrastructure that support employee performance. After all, every system is perfectly designed to get the results that it brings.

Many books and articles about good leadership focus on interpersonal relationship skills like communication, humility, and empathy. Of course, all of these traits are important for good leadership. Still, they don't directly address the most critical responsibility of a leader, which is to create systems and infrastructure that support employee performance. After all, every system is perfectly designed to get the results that it brings.

While it is tempting to blame problems and performance misses on people, the reality is that even the most skilled and dedicated employees are only as effective as the processes they operate. Therefore, if you want to improve your leadership, it makes sense to recognize this and focus your energy on improving processes and empowering employees to engage in process optimization.

What is a Process?

Some processes, like a factory assembly line or a grocery store checkout line, are apparent, but in reality, every task and operation in an organization is a part of a process. Processing invoices, acquiring raw materials, checking in patients, and quality assurance testing are all processes. Together, the many processes an organization operates form a system that creates some value for the customer. Operationally excellent organizations create maximum value with minimal waste.

So what does process-oriented leadership look like, and how can you begin to implement it?

Develop Leader Standard Work

Leader Standard Work is a set of actions, behaviors, and tools incorporated into leaders' work every day. The goal of leader Standard Work is to improve performance, reduce variation, develop team members, and demonstrate how to make constructive changes. It defines what, how, and when the leader should take action.

Related: How (and Why) To Standardize Leadership

Work with Process Operators to Define the Current Best Practice (Standard Work)

Before you can alter a process and determine if improvement has been achieved, you must first ensure that the process is operated consistently, no matter who does it. The first step is to define the current best method for each activity and task. As a leader, you should look to those doing the work to define and document the Standard. Once the Standard is in place, you and your team can evaluate its strengths and weaknesses to look for opportunities for improvement.

Regularly Visit the Workspace

Gemba Walks are a continuous improvement practice in which leaders visit the place where work is done to show respect, observe, and ask questions. This is different from the Management by Walking Around approach because it is purposeful. When opportunities for improvement are observed or offered by team members, the leader reflects on them and structures a plan before making any changes. Workplace visits are also an opportunity to identify gaps between the Standard and the actual work and ask questions about why the Standard isn't followed. The goal is not to blame people but rather to understand what factors contribute to this variation.

Apply Solutions to the Root Cause of Problems

One of the most tempting and damaging impulses is to improve processes by applying fixes for symptoms. Many organizations operate with a series of workarounds and Band-aids. Instead of falling into this trap, effective leaders dig deeper until they find the root cause of problems and find a way to address the issue at its source. The 5 Whys is a problem-solving technique that can help you become a better leader. You simply state the problem and ask "Why?" until the underlying issue is uncovered. The number of iterations will vary based on the problem, but five usually does the trick.

Related: The 5 Whys: A Ridiculously Simple Yet Essential Problem Solving Tool

Implement a Structured Improvement Cycle

Another helpful method for improving processes is a structured improvement cycle. One of the most widespread is the PDSA cycle, also called the Demming cycle, named after Dr. W. Edwards Deming, considered by many to be the master of continual quality improvement. PDSA is an acronym for:

Plan: State the problem and its root cause. Establish baseline metrics for the process. Identify people who should be involved in the solution. Identify the best potential solution and establish a timeline for action.

Do: Implement the proposed solution. Ensure that all process operators are adhering to the new method. It is essential to implement only one change at a time so that you know the impact of each adjustment. If multiple changes are needed to solve the problem, use an incremental approach.

Study: Gather results of the modified process. Get feedback from process operators. Look for any unintended side effects. If there was a cost involved in the improvement, determine whether the change was profitable.

Adjust: If the change resulted in measurable improvement, change the Standard to the new method. If improvement was not realized, try a different solution for the root cause problem.

Use Visual Process Control Tools

An important tool for both the Plan and Study phases of PDSA is the process control chart. Visualizing process outcomes is the best way to determine whether the process is in a steady-state or if something significant has changed. Data points are plotted in time order in a chart with a center line for the average, an upper line for the upper control limit, and a lower line for the lower control limit. These charts help leaders avoid reacting to every unimportant up and downswing.

Related: A Simple Introduction to Putting Process Control Charts to Work

Align Goals and Objectives

If you want to be recognized as a great leader, it is vital to make sure your process improvement work is aligned with the overall goals and objectives of the organization. While your process improvement work is most likely tactical, it should further the strategic plan. As you think about goals, make sure that each individual within your team also has goals in line with the overall objectives.

Measure the Impact of Process Change

It is essential that you can quantify the results of your process improvement efforts. Some improvements will have a financial impact, but others will be measured by increased customer satisfaction, reduced cycle time, fewer safety incidents, improved quality, or other key performance indicators.

Foster Employee Engagement

Great leaders don't just take action; they inspire others to act as well. Everyone on your team should be involved in your continuous improvement efforts. Employees should engage by pointing out opportunities for improvement, defining Standard Work, and working through your structured improvement cycle. As employees become adept at implementing improvement, they can take on increasing responsibility for change control and management.

Consider Software to Accelerate Improvement

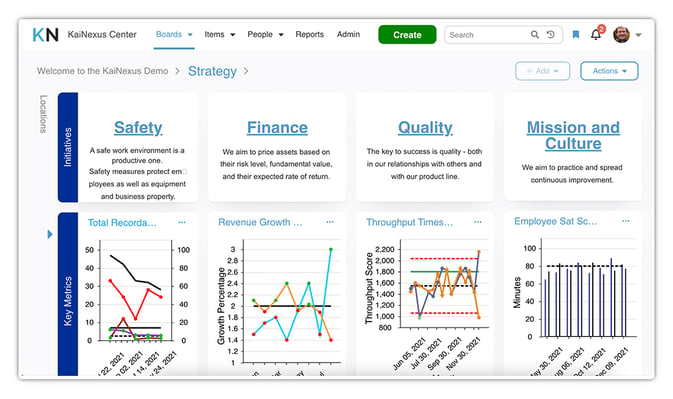

Continuous improvement involves many moving parts and a significant amount of data to manage. Fortunately, there are software platforms that make it easy to collect, implement, measure, and share improvement activities. Alerts and notifications ensure that everyone is up to speed, and configurable dashboards give each person easy access to the most needed information. In addition, the software application becomes a repository of knowledge for your organization so that each time you implement an improvement project, you are learning from what's been done in the past and getting more thoughtful about how you approach each new challenge.

Whether you lead an entire organization or a small team, you can become a better leader by improving processes and helping your team members do the same.

![[WEBINAR] Bottom-Up Improvement Software Demo](https://no-cache.hubspot.com/cta/default/326641/8545f357-84e1-47b2-81e0-f4fa0d3cd893.png)

Add a Comment