Jeff Roussel

Recent Posts

What is Kaizen? Everything Your Team Needs to Know

February 2, 2022In 1986, Masaaki Imai introduced the world to the philosophy and practice of Kaizen in his book Kaizen, The Key to Japan’s Competitive...

11 Fundamental Kaizen Principles

February 22, 2021In Japanese, the word Kaizen means "good change." It describes the continuous improvement of all functions of an organization across the...

Software's Role In Measuring Continuous Improvement

February 15, 2021The most common way organizations manage continuous improvement is with an assortment of improvement tools, spreadsheets, and email. We...

How (and Why) to Standardize Leadership

December 15, 2020While most people agree that process operations should be standardized as much as possible, the topic of standardizing leadership comes up...

Best Principles for Continuous Improvement in Manufacturing

June 22, 2023These days, organizations of all types embrace the concept of continuous improvement. Still, there's a reason that many of the most popular...

Lean Software for Healthcare Organizations

December 16, 2020The Lean business approach is becoming increasingly popular in healthcare organizations. Leaders have discovered that Lean is a perfect fit...

10 Questions to Ask Before Buying Improvement Management Software

September 21, 2020Evaluating software for any purpose is a difficult task. You need to think about the technical infrastructure, user experience, features,...

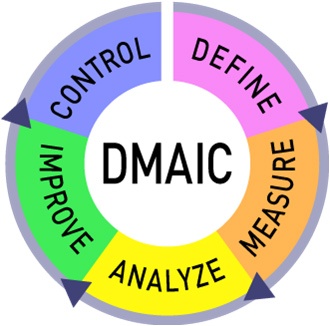

The 5 Phases of the DMAIC Improvement Cycle

August 17, 2020The DMAIC improvement cycle is a structured, data-centric approach to problem-solving. DMAIC (pronounced də-MAY-ick) stands for "Define,...

Process Improvement 101 – Basic Techniques

June 15, 2020When we chat with people about their business goals, many reveal that the idea of business process improvement is somewhat overwhelming....

How to Choose an Improvement Platform

June 2, 2020The selection process for any type of software can be challenging to navigate. You’ve got to find out what’s available, narrow down your...