People often use the terms quality assurance and quality control interchangeably. However, although they are similar, there are essential differences between the two ideas. Each is a piece of the quality management puzzle. While some quality assurance and quality control activities are related, the goals and tools of each are different.

People often use the terms quality assurance and quality control interchangeably. However, although they are similar, there are essential differences between the two ideas. Each is a piece of the quality management puzzle. While some quality assurance and quality control activities are related, the goals and tools of each are different.

Quality Assurance and Quality Control Definitions

Before we dig in, it makes sense to start with a definition of quality. A simple and often used definition is from Mr. Philip B. Crosby, a well-respected quality management expert. He viewed quality as “Conformance to requirements.”

ISO 8402:1996 says, “Quality is the totality of features and characteristics of a product or service that bears on its ability to satisfy stated or implied needs.” According to ISO 9000:2000, “Quality is the degree to which a set of inherent (existing) characteristics fulfills requirements.”

In short, “quality” means meeting the customer’s requirements that the deliverable is fit for use.

Quality assurance (QA) consists of actions taken to design and produce a safe and effective product that meets customer requirements by building quality controls into the product life cycle. It includes all of the planned and systematic activities within the quality system that allow for confidence that the product or service will meet all quality requirements.

While quality assurance is about how a product is produced and how processes are performed, quality control is about inspection. It includes the operational techniques and activities used to verify that a product or service meets quality requirements. Quality inspections can happen pre-production when the raw materials or parts from other suppliers are validated at various points during production and then again once the final product is produced.

Together, quality assurance and quality control work to prevent defects and identify them when they occur. Both are necessary. Relying on quality control alone won’t reduce defects. Understanding the distinctions between the two will highlight the reasons both should be applied.

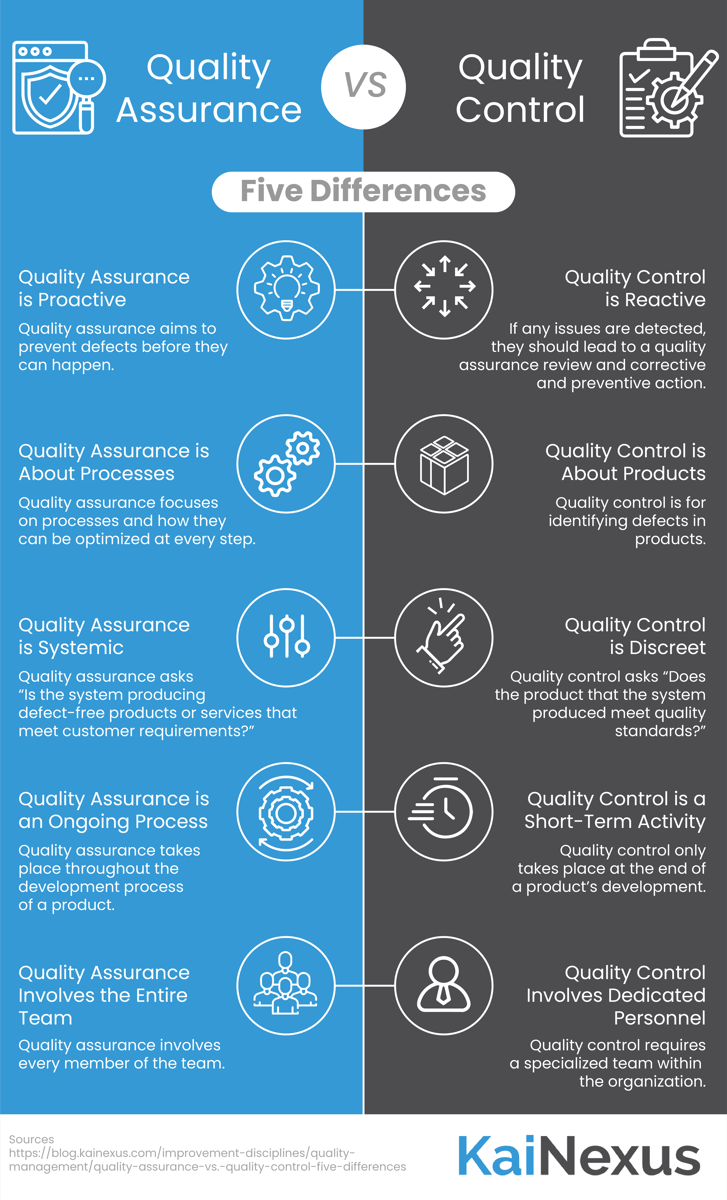

1. Quality Assurance is Proactive while Quality Control is Reactive

The goal of quality assurance is to prevent defects before they happen through thoughtful process design. Thus, it is a proactive approach. On the other hand, the goal of quality control is to identify defects after they have happened and respond reactively.

With effective quality assurance, the design of processes, including standard work procedures, workspace organization, training, and visual management, is such that errors will be rare or non-existent. Ideally, a safe, effective product that meets customer requirements will happen every time the process is repeated. Thus, quality control takes place after an operation is complete and, in the best case, prevents defective products from reaching customers.

Issues uncovered during quality control should lead to a quality assurance review and corrective and preventative action. Once the root cause of the problem is found, processes are changed to prevent the problem from happening again.

2. Quality Assurance is About Processes while Quality Control is About Products

Quality assurance is directed at processes, baking in quality at every step. Quality control is product-oriented and focused on identifying defects in products. You might think of the difference as actions (QA) vs. results (QC). Examples of the activities involved for each make the distinction more clear.

Quality Assurance Processes and Tools

-

- Standard work

- Documentation

- Change control

- Workspace organization

- Employee training

- Audits

- Gemba walks

Quality Control Procedures and Tools

-

- Batch inspection

- Validation testing

- Product sampling

- Laboratory testing

- During production inspection

- Defects per opportunity measure

3. Quality Assurance is Systemic while Quality Control is Discrete

Quality assurance and quality control are both methods of safeguarding quality standards, but each answer different questions. Quality assurance asks, “Is the system producing defect-free products or services that meet customer requirements?” While quality control asks, “Does the product that the system produced meet quality standards?”

In some cases, quality control efforts may also be applied to the inputs used to create the product, such as raw materials or parts provided by a supplier. Activities such as auditing suppliers and batch sampling raw materials are examples of this practice.

4. Quality Assurance is an Ongoing Process, while Quality Control is a Short-Term Activity

In some ways, quality assurance is like a movie, while quality control is more of a snapshot. The process of creating a product may take many days or weeks; all the while QA activities are taking place, only at the end is the final result available for QC inspection. Elements of quality assurance also evolve over time as improvements to processes are implemented. Quality control, on the other hand, is usually well-defined and consistent over time.

5. Quality Assurance Involves the Entire Team, while Quality Control Involves Dedicated Personnel

Every team member has a role in quality assurance, even if it is to simply follow standard work. For example, each time an employee recognizes and reports an opportunity for improvement, they participate in QA. Likewise, those who set standards for training, document procedures, participate in 5S, and implement corrective actions are all taking part in quality assurance.

In most cases, quality control via inspection is the responsibility of designated people within the organization, including product testing. These employees document and report defects and trigger a response when needed.

Quality Assurance and Quality Control in a Quality Management System

Quality assurance and quality control are necessary to produce products that meet customer requirements for safety and efficacy. Therefore, it is impossible to say which is more important. A focus only on inspection leads to waste and potential defects that make it to the customer. At the same time, quality control is necessary to validate that process-oriented thinking results in products that meet quality standards.

Quality control and assurance are easiest to manage when incorporated into a quality management platform designed to support end-to-end quality processes. A single online solution can integrate activities related to quality outcomes, including document control, opportunity management, data visualization, training, and CAPA management.

When both quality assurance and control are effectively implemented, organizations can be confident that customers will receive products and services that are free of defects and that they meet customer requirements.

Add a Comment