Whether or not your organization fully embraces the Lean manufacturing business paradigm or just borrows some of its best practices, the methodology has many valuable tools and techniques. There are so many that it can be challenging to decide which one to use for a given project or problem. There’s no “right” way to apply lean tools to achieve continuous improvement, but there are some situations for which particular techniques are generally well suited.

We’ve broken down the most valuable tools that can be leveraged to support daily improvement, problem-solving, waste elimination, and strategic planning in this post. Before we get into specific tools, however, it is helpful to understand the common goals of all Lean tools. Each performs one or more of the following functions:

- Communicate Information

- Define and Share Standards

- Enforce the Standards

- Bring Attention to Variation

- React to Variation

- Prevent Variation from Occurring

Lean practitioners deliver maximum value to the customer by eliminating waste and creating processes that produce consistent, predictable results. These Lean management and total quality tools are used to achieve those goals.

Standard Work

Before any improvement project can begin, there must be a baseline from which to start. Standardized work is simply the documentation of the current best practice for any process or task. It is crafted by the process operators and continuously maintained. Standard work documentation must be accessible in the workspace where the job is performed. Everyone operates the process according to the standard work until it is adjusted following a structured improvement cycle.

PDSA

PDSA is a widely-used rapid improvement cycle. The phases are Plan, Do, Study, Act. During the Plan phase, the problem and the desired future state are defined, and a hypothesis is reached as to what might result in improvement. Next, the measure of success and any other KPIs are selected. The "Do" part consists of implementing the proposed change and collecting data for comparison. The data is then studied to determine if the change did result in the desired improvement. If so, it's time to Act and make the change a permanent part of the standard work. PDSA is one of the most critical Lean tools for reducing waste.

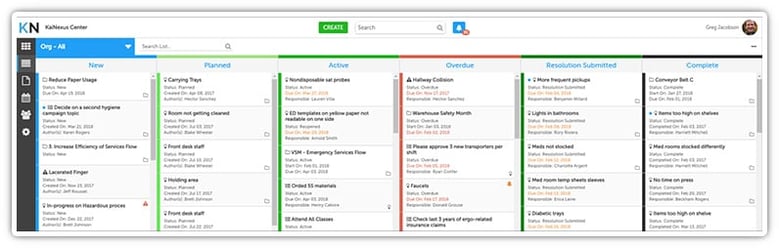

Kanban Boards

Kanban boards are a visual management tool for all of the improvement projects your team is working on at any given time. Visualizing work-in-progress makes daily improvement easier to manage for process operators and leaders alike. Work is moved across the board from idea to completion. The simple design of Kanban makes it easy to see when there are backlogs or when work is waiting for inputs. Digital Kanban boards are an excellent approach because people can access them from anywhere, and they create a record of past improvement work for future learning.

5S Workplace Organization

An organized workspace is essential if the goal is to increase productivity and eliminate variation. The Lean tool for workplace organization involves five steps that start with an S in both English and Japanese. They include seiri (sort), seiton (set), seiso (shine), seiketsu (standardize), and shitsuke (sustain).

Organizations that use the 5S methodology increase efficiency because many of the obstacles that slow people and systems down have been eliminated or mitigated to allow smoother operations. Waste reduction is another significant benefit of 5S. 5S also increases employee engagement and satisfaction by empowering employees to make improvements to their workspace.

Gemba Walks

Gemba walks are a Lean practice in which leaders and supervisors go where work is done to observe, show respect for employees, and identify potential opportunities for improvement. The technique involves asking questions about why workers are completing tasks a certain way and understanding the workers’ relationship to their environment.

Kaizen Events

Sometimes problems are so impactful or urgent that you need people to set aside other priorities and concentrate on solving them. That's when it is time for a Kaizen event. During a Kaizen or rapid improvement event, a team is selected to focus all of their attention on the issue at hand over a three to five-day period. Kaizen events are guided by a project charter and led by a team member or a professional facilitator.

A3 Problem-Solving

The A3 Report is a problem-solving and tool that Toyota developed. Leaders at Toyota believed that even the most complex problems could be documented on a single sheet of paper. This level of precision helps everyone concentrate on the same set of facts. In addition, the structure of an A3 report brings another level of sophistication and control with the PDSA cycle at its heart, a must for difficult-to-solve challenges.

The 5 Whys

One brilliantly simple Lean tool is the 5 Whys. Its goal is to find the root cause of a problem to apply an improvement to the reason rather than the symptoms. When using the 5 Whys technique, you simply state the problem and then continue to ask why until the underlying flaw in the system is revealed. It usually takes about 5 iterations to find the cause.

Control Charts

A process control chart is a graph that is used to visualize how a process performs over time. Data points are plotted in time order in a chart with a central line for the average (or median), an upper line for the upper control limit, and a lower line for the lower control limit. Process control charts help in problem-solving by clarifying the difference between normal process fluctuation and significant variation.

Hoshin Kanri

In Japanese, Hoshin means "compass needle" or "direction," and Kanri means "management" or "control." In practice, it means that management has control of where the organization is going. This is made possible by following the guiding principles:

- Objectives are communicated

- There is a deep understanding of the current state

- There is widespread engagement in crafting and executing the strategy

- Resources are prioritized according to the plan

- Precision tracking of performance is constant

Catchball

Catchball is a Lean technique for creating and maintaining open feedback loops across all levels of your organizational hierarchy by creating a two-way stream of information sharing. The strategy proposal is tossed like a ball giving team members at various levels of the organization an opportunity to provide feedback and ideas.

Catchball is an effective technique for ensuring that employees understand how they fit into the strategic picture, making them more connected to the organization's most important objectives.

One tool that cuts across every one of these situations is Lean software. It can be used to support and document each of the techniques we mentioned. Not only that, but it helps your organization get smarter by creating a center of collected wisdom to help your team make every improvement more impactful than the last.

![[WEBINAR] A Deep Dive into A3 Thinking](https://no-cache.hubspot.com/cta/default/326641/a78d9f1b-c108-4709-8a9d-9dd5a8a020b3.png)

![[WEBINAR] Strategy Deployment Software Demo](https://no-cache.hubspot.com/cta/default/326641/67b72769-975a-48b1-b5d8-4ba0fe1f3b76.png)

Add a Comment