Lean Software Helps Organizations Tackle the 8 Wastes

February 17, 2022Lean organizations look to minimize eight types of waste to create a flawless flow of value to the customer. In a perfect world, no...

A Quick Guide to 5S Workplace Organization

December 7, 2020The 5S workplace organization technique is a prevalent methodology that companies can use to improve operations. The intent is to improve...

Best Principles for Continuous Improvement in Manufacturing

June 22, 2023These days, organizations of all types embrace the concept of continuous improvement. Still, there's a reason that many of the most popular...

7 Common Auto Manufacturing Continuous Improvement Tools

December 16, 2020The Lean and Six Sigma business methodologies have deep roots in the automotive manufacturing sector. One of the reasons they are so...

Lean Software for Healthcare Organizations

December 16, 2020The Lean business approach is becoming increasingly popular in healthcare organizations. Leaders have discovered that Lean is a perfect fit...

How Technology Helps Control the 8 Wastes of Lean

November 3, 2020Many organizations look to minimize the eight types of waste identified in the Lean business methodology. The goal is to create a shameless...

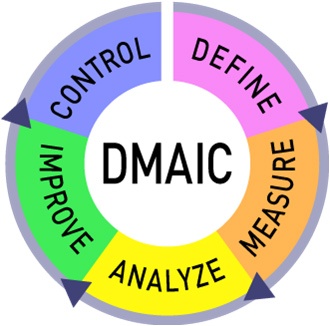

The 5 Phases of the DMAIC Improvement Cycle

August 17, 2020The DMAIC improvement cycle is a structured, data-centric approach to problem-solving. DMAIC (pronounced də-MAY-ick) stands for "Define,...

9 Reasons to Consider a Lean Management System

August 10, 2020We talk to people who are looking for ways to get more efficient with their continuous improvement efforts every day. Many are already...

9 Cloud-based Lean Tools

August 3, 2020Organizations that embrace the Lean method of business management have many tools and techniques that they can deploy. That's one reason...

9 Benefits of Lean Management Software

June 15, 2020The Lean management methodology is popular across almost every industry. We have customers in sectors from healthcare to construction that...

.png)