Ryan Rippey

Recent Posts

An 11 Step Gemba Walk Template for Executive Leaders

July 10, 2025“We say seeing is believing, but actually, we are much better at believing than seeing. In fact, we are seeing what we believe all the...

Webinar | Metrics & Statistics Don't Have to be Scary

March 7, 2019A while back, we recently had the honor of hosting a webinar with our Senior Advisor, Mark Graban, author of "Measures of Success: React...

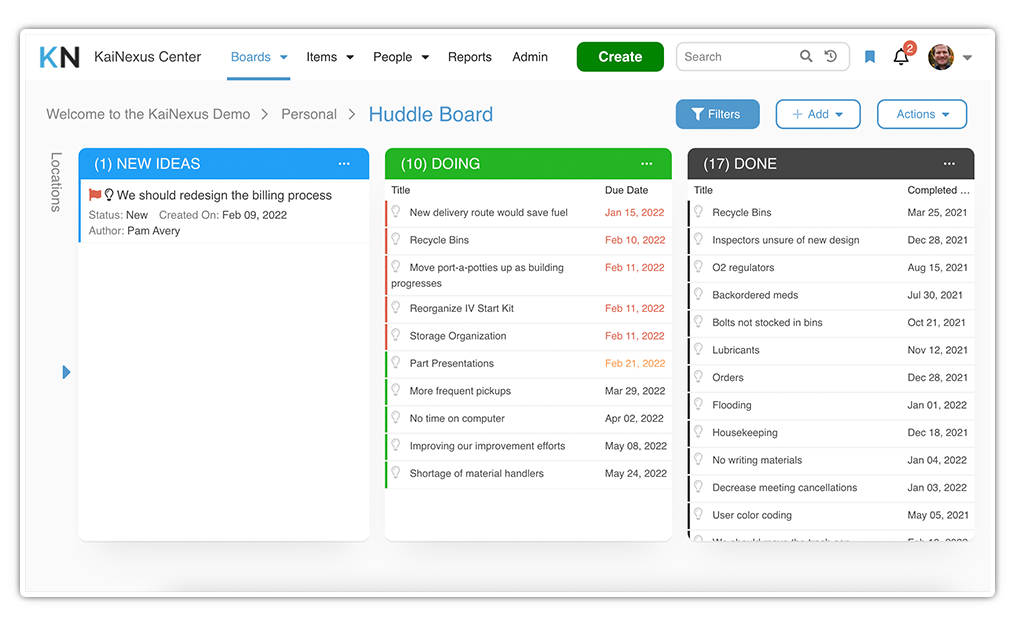

The Lean Visual Management Tools Your Team Will Love

January 28, 2019Although the overarching objective of Lean management is to create an unhindered flow of value to the customer, another of its primary...

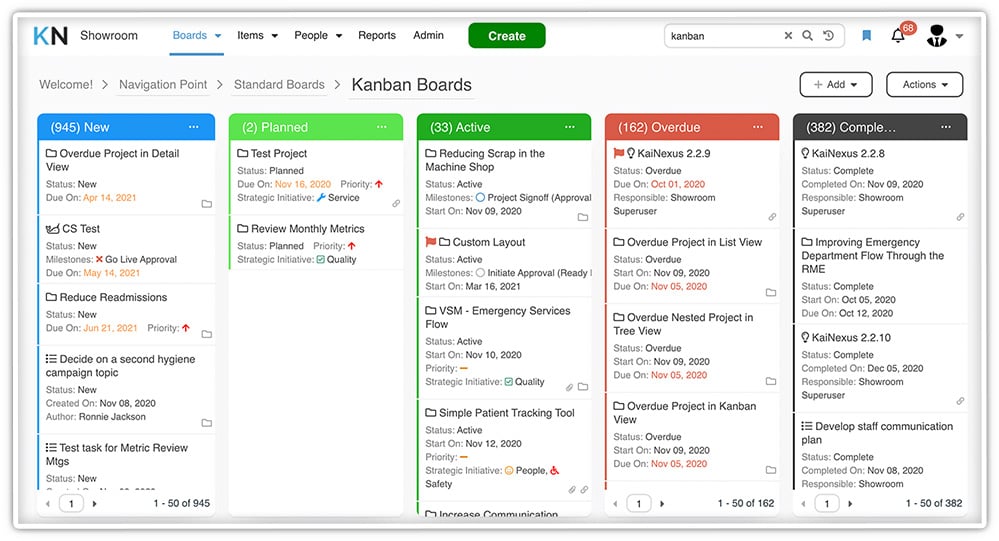

9 Reasons to Consider a Digital Kanban Management Tool

January 9, 2019As you might expect, we write quite a bit about Lean and Six Sigma management techniques that have been modernized by moving to digital...

What Should You Include in Your Hoshin Kanri Training Materials?

January 4, 2019If you’ve been tasked with introducing the Hoshin Kanri strategy deployment methodology to your organization, and you are like many of our...

The Essential CQI (Continuous Quality Improvement) Glossary

December 20, 2017CQI, like many other disciplines, has a language all its own. Many of the terms are acronyms, others are Japanese words retained from...

Want to Get More Out of Rapid Improvement Events? Click Here.

November 28, 2017Rapid improvement events are a popular continuous improvement approach with for good reasons. By focusing all of your team’s firepower on...

A Mission to Partner with Patients to Improve Safety

September 21, 2017If you’ve been following our blog, watching our webinars (which are available on demand), or listening to our podcasts for a while, you’ll...