Top 8 Reasons that CQI Initiatives Fail

August 29, 2017Continuous quality improvement (CQI) isn’t a subject that inspires a lot of debate. We’ve yet to find a business leader or even a...

Continuous Improvement Leadership at Mohawk Paper

April 26, 2017Though we work hard to give you as much information as we can about continuous improvement (CI) and the many related methodologies, we...

A Pilot and a Focus on Engagement: Continuous Improvement at Mohawk

April 14, 2017One of the most interesting things about working with new clients at KaiNexus is that we get to hear stories about how organizations have...

Turning a PMO & Continuous Improvement into an Innovation Team

February 11, 2020We love highlighting Lean success stories here at KaiNexus and so we were very excited when Erin Edwards, Continuous Improvement Manager at...

Should You Introduce Improvement Software to Your Over-Loaded Staff?

January 26, 2017One of the most common worries we hear about from people getting ready to introduce a continuous improvement software solution is that...

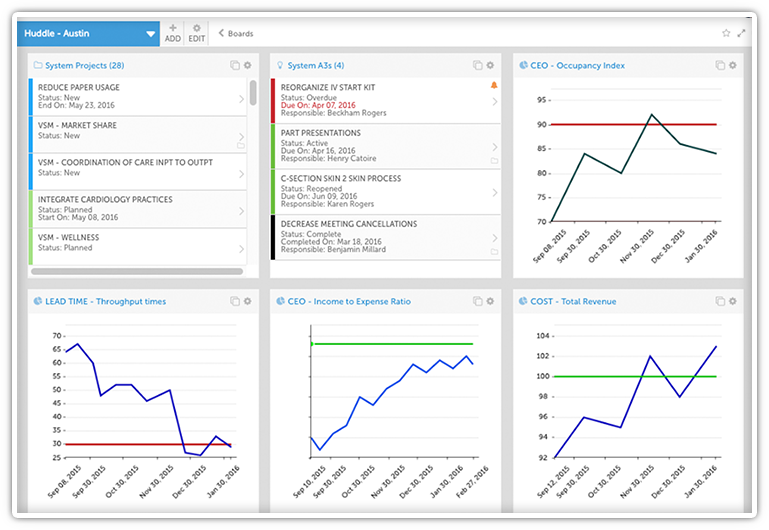

How to Drive Performance Improvement Using KaiNexus in Healthcare

January 4, 2017Identify, Specify and Create Value for the Users

Kristin Bentz, RN, BSN, CPHQLean Transformation Specialist, LeeHealth

I am a registered...

Yes, You Can Spread an Improvement Culture with Limited Resources

January 22, 2018Hint: Continuous Improvement Software Makes it Possible

Creating a unified culture of continuous improvement, rolling out new software to...

Why This Organization Turned to Continuous Improvement Software

February 11, 2020When Dr. Tania Lyon became the first Director of Organizational Performance Improvement for St. Clair Hospital, continuous improvement...

A Lean Transformation From a Struggling ED to Top Notch

July 27, 2016Here at KaiNexus, we have some pretty impressive customers and we work with very talented, passionate people every day. One such individual...