The Development & Use of the PDSA Cycle of Improvement

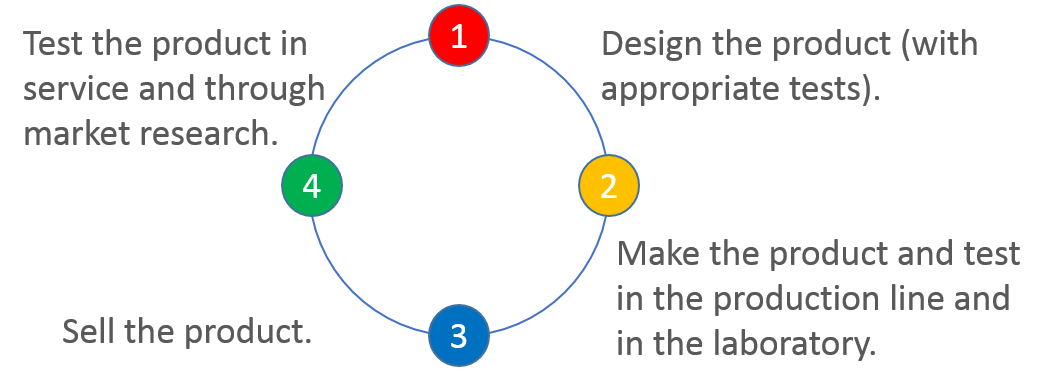

January 20, 2022The PDSA cycle is a popular approach to process improvement because of its simultaneous simplicity and effectiveness. Although it started...

What is a Business Process Improvement Methodology?

April 18, 2024Business process improvement is a management practice that helps leaders leverage several tools and techniques to analyze their processes...

What is Policy Deployment and How To Reach True North

December 29, 2021Policy deployment, known in Lean circles as Hoshin Kanri or Strategy Deployment, is a technique for ensuring that an organization's...

Three Steps to Applying the A3 Problem-Solving Methodology

December 14, 2021The A3 problem-solving methodology was first used by Toyota in the 1960s and later embraced by proponents of Total Quality Management, Six...

Enhancing Positive Change with Continuous Improvement Technology

June 5, 2023If you look around any public space today, odds are you will see more than one person with a phone in their hand or pressed up to their...

Actionable Tactics for Shaping Organizational Culture

March 11, 2024Most leaders recognize that organizational culture has a significant impact on success. Delivering on strategic objectives requires that...

How to Create a High-Performance Organizational Culture

December 7, 2021An organization's culture is the foundation upon which success, stagnation, or failure is built. It is imperative during times of growth or...

Continuous Process Improvement Methodology Definitions

November 30, 2021Long-term business survival requires constantly re-assessing and improving business processes. Continuous process improvement allows for...

9 Easy to Deploy Continuous Quality Improvement Tools

November 24, 2021Quality management programs are often associated with large organizations, such as automotive manufacturing or large healthcare systems....