What Are the 8 Wastes of Lean and How Can You Eliminate Them?

July 21, 2025Summary

Waste exists in every business, often hidden within daily operations. The 8 wastes of Lean—defects, transportation, waiting,...

What is Lean? | Lean Business

January 16, 2025The modern business landscape is full of buzzwords and passing management fads, so it isn't surprising if you hear of a new "methodology"...

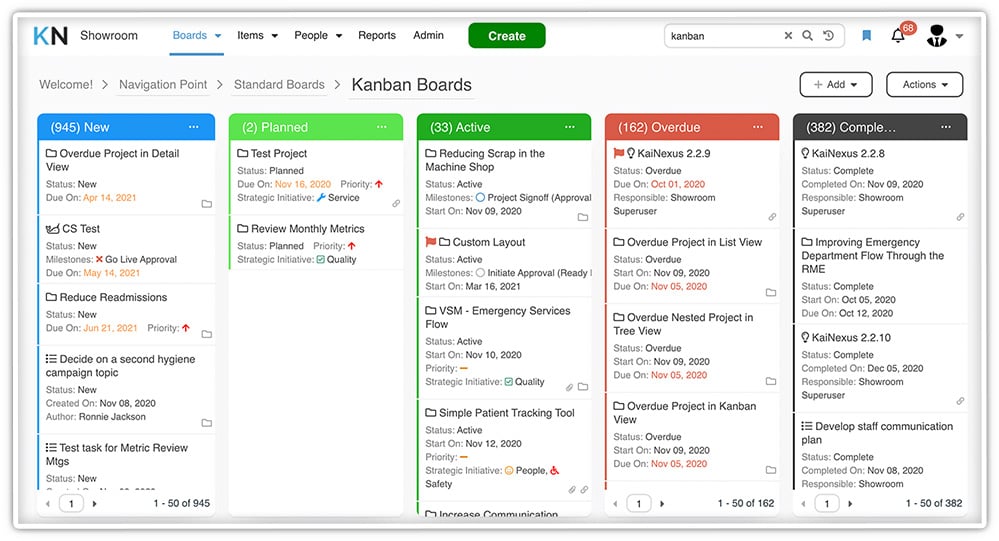

How Visual Management Tools Start & Sustain Improvement

December 23, 2024Visual management tools surround us. Although they are so ubiquitous, we might not even think about them. For example, when your car is...

5 Whys: A Simple Tool for Root Cause Analysis and Goal Setting | KaiNexus

December 17, 2024The 5 Whys technique is a cornerstone of Lean management and continuous improvement practices. Originally developed as part of the Toyota...

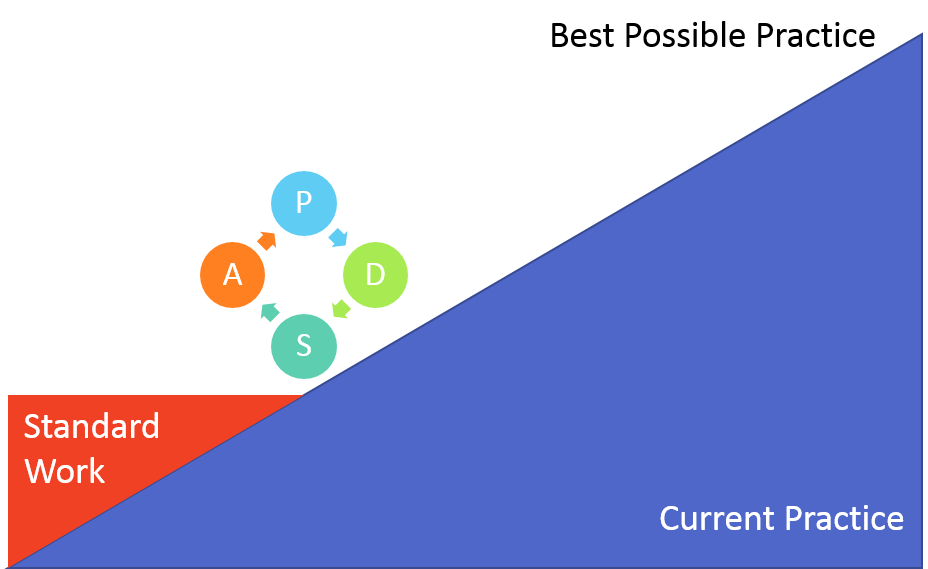

How Does Standard Work Drive Continuous Improvement in Organizations?

September 2, 2025Standard Work serves as the foundation for all continuous improvement efforts by establishing consistent, documented processes that create...

Key Objectives and Activities for Each Step of DMAIC

October 25, 2024DMAIC (Define, Measure, Analyze, Improve, Control) is a data-driven, structured, customer-centric problem-solving methodology. Each phase...

How Lean Healthcare Management Can Elevate Patient Care

January 5, 2026Although the Lean quality improvement methodology was initially developed to improve the quality and productivity of automotive factories,...

A Quick Guide to the Basic Ideas of Lean Manufacturing

August 28, 2024Lean manufacturing is a process improvement methodology that started in the Japanese automotive manufacturing sector after World War II....

12 Characteristics of a Lean Organization

June 20, 2024The renowned football coach and philosopher Vince Lombardi once said, “Perfection is unattainable, but if we chase perfection, we catch...