Ten Years of Questions: The Ask Us Anything Insights That Still Hold Up

February 24, 2026Ten years of answering questions from CI practitioners taught us that the hardest problems aren't technical -- they're human. Leadership...

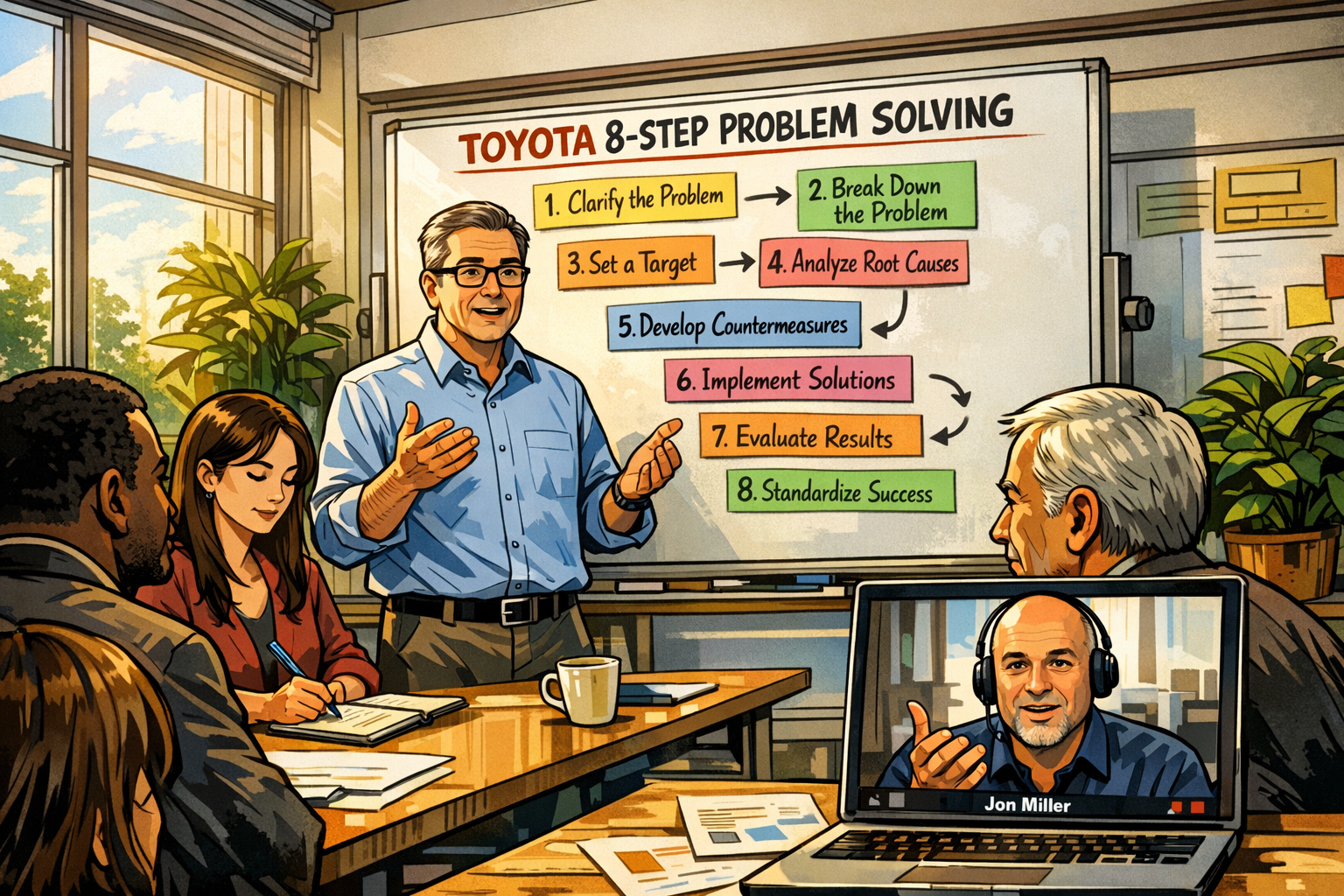

Go Slow to Go Fast: What I Learned from Jon Miller About 8-Step Problem Solving

February 19, 2026TL;DR:Continuous improvement stalls when teams skip disciplined problem solving. Jon Miller’s overview of Toyota’s 8-step framework...

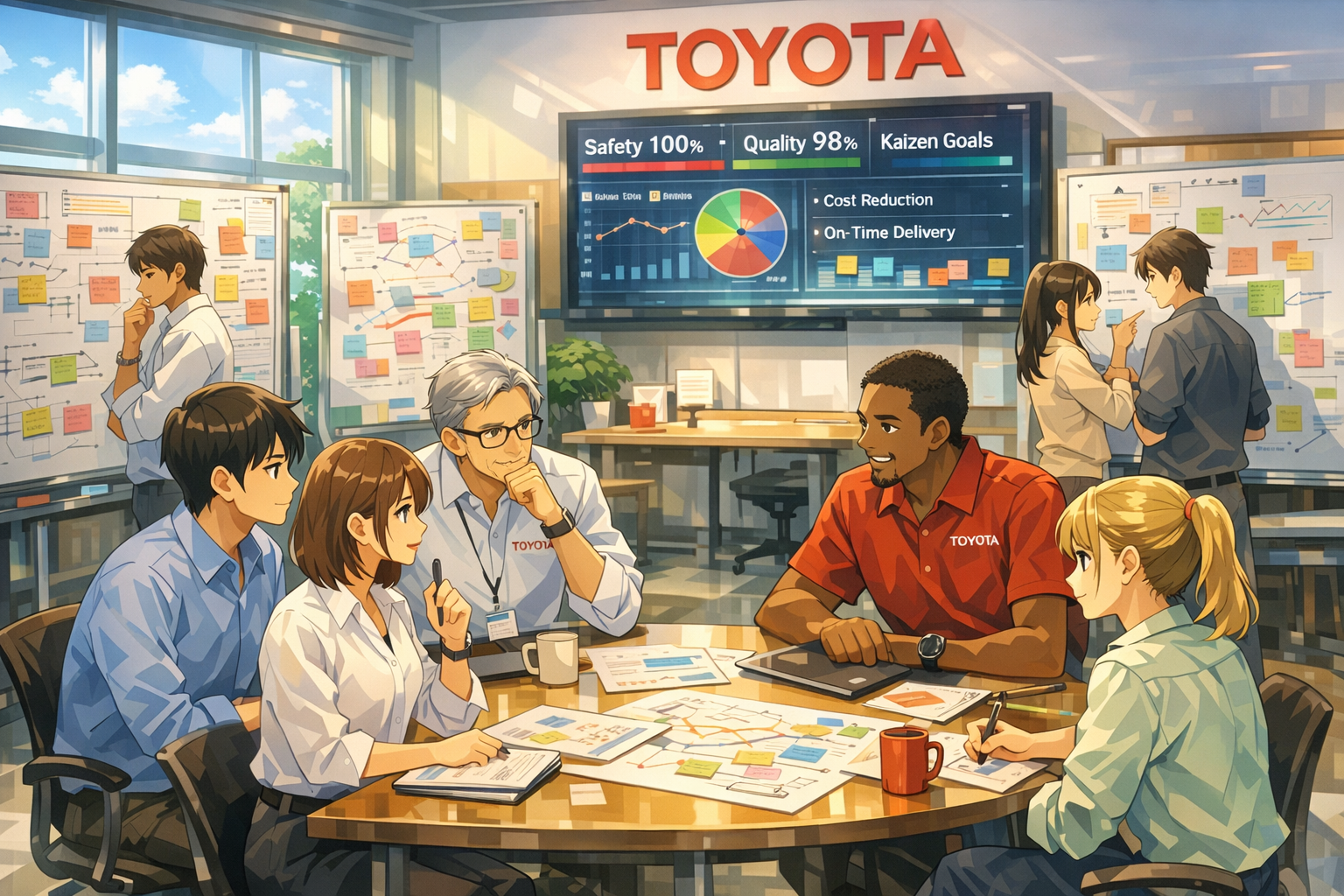

Mutual Trust and Respect in Lean: Toyota’s Real Competitive Advantage

February 18, 2026TL;DR: Toyota’s real competitive advantage is not its tools -- it is mutual trust and mutual respect. Leaders are responsible for...

Respect for People in Lean: What It Really Means and Why It Drives Continuous Improvement

February 16, 2026TL;DR: Respect for People is the foundation of Lean management. It means engaging employees as problem solvers, creating psychological...

The CEO’s Role in a Continuous Improvement Business System

January 20, 2026Many executives say they want a culture of continuous improvement.

What they often struggle to articulate is what that actually means in...

Why Pursuing Zero Harm Still Matters as a Leadership Strategy

January 14, 2026When we hosted the webinar Pursuing Zero Harm: A Powerful Platform for Embedding Lean Capability with Meghan Scanlon, the discussion...

Looking Back: Why A3 Thinking Still Matters—At Work and Beyond

January 9, 2026When we hosted the How to Use A3 Thinking in Everyday Life webinar with Jess Orr, the premise was intentionally a bit provocative. A3...

The Unified Approach: Connecting Strategy, Process, and People in Operational Excellence

December 13, 2025For organizations committed to Operational Excellence (OpEx), the challenge is rarely a lack of ideas or ambition. The struggle often...

Interview Questions to Hire Continuous Improvement Employees

January 5, 2026Quick Answer: Ask questions that reveal whether candidates are open to feedback, willing to identify problems, capable of learning from...