Recent Posts

What Does Continuous Improvement With Lean Systems Mean in Manufacturing?

October 12, 2023Continuous improvement, often called Kaizen, is a fundamental concept in manufacturing that emphasizes the ongoing, incremental enhancement...

Top 15 Process Improvement Tools to Enhance Workflow Performance

July 13, 2023Organizations implement process improvement initiatives, using various process improvement tools, to drive operational excellence, enhance...

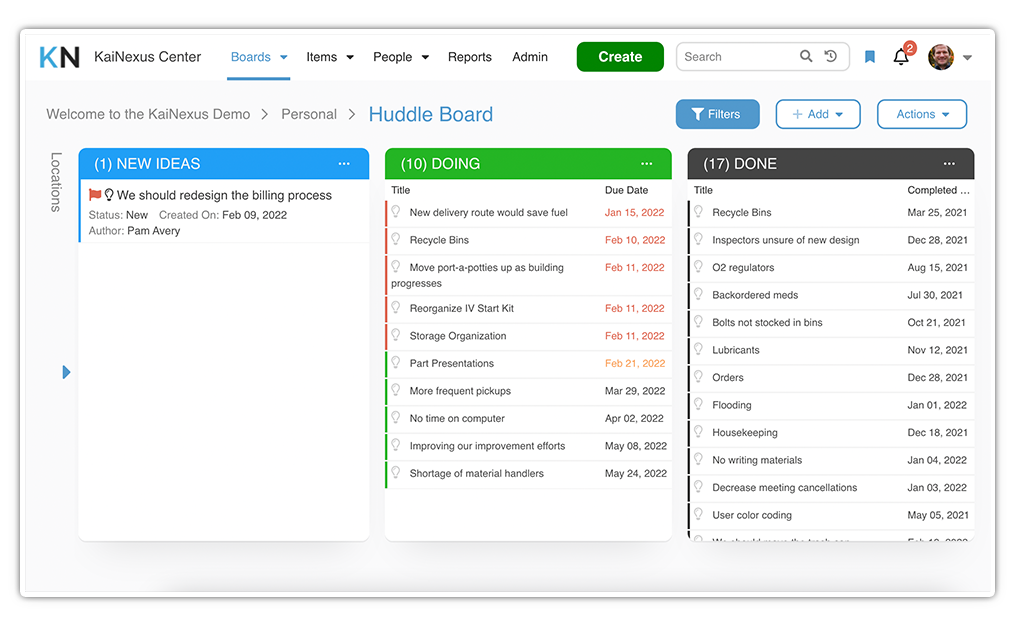

Huddle Board Examples to Encourage Collaboration

January 10, 2023One of the fundamental principles of continuous improvement is that positive change is the responsibility of every employee. Embracing that...

How to Use The Hoshin Kanri X-Matrix to Deploy Your Strategic Plan

October 19, 2022Now is the time of year when many leaders turn their thoughts to crafting the strategic plan for next year. In most cases, this involves...

What is a Business Process Improvement Methodology?

April 18, 2024Business process improvement is a management practice that helps leaders leverage several tools and techniques to analyze their processes...

5S: The Lean Gold Standard for Workplace Organization

September 13, 20215S is a Lean manufacturing technique that addresses the organization of workspaces and work processes for a safer and more efficient...

A Structured Approach to Problem-Solving | Webinar Recap

June 9, 2021We had the pleasure of presenting a webinar hosted by Chad Westbrook, a manufacturing engineering manager and AGCO production system...

Continuous Improvement Predictions for 2021

December 8, 2020If you think trying to predict anything that will happen in 2021 is insane after what’s happened this year, you have a point. But by...

Beyond the Problem – Bonus Benefits of Kaizen Events

October 21, 2019Kaizen events, sometimes called rapid improvement events, are an effective way of solving difficult challenges within organizations. A team...